Vehicle body position detection method for washing vehicles

A detection method and vehicle body technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of complex structure, inability to be used for accurate identification, weak detection ability, etc., and achieve the effect of high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

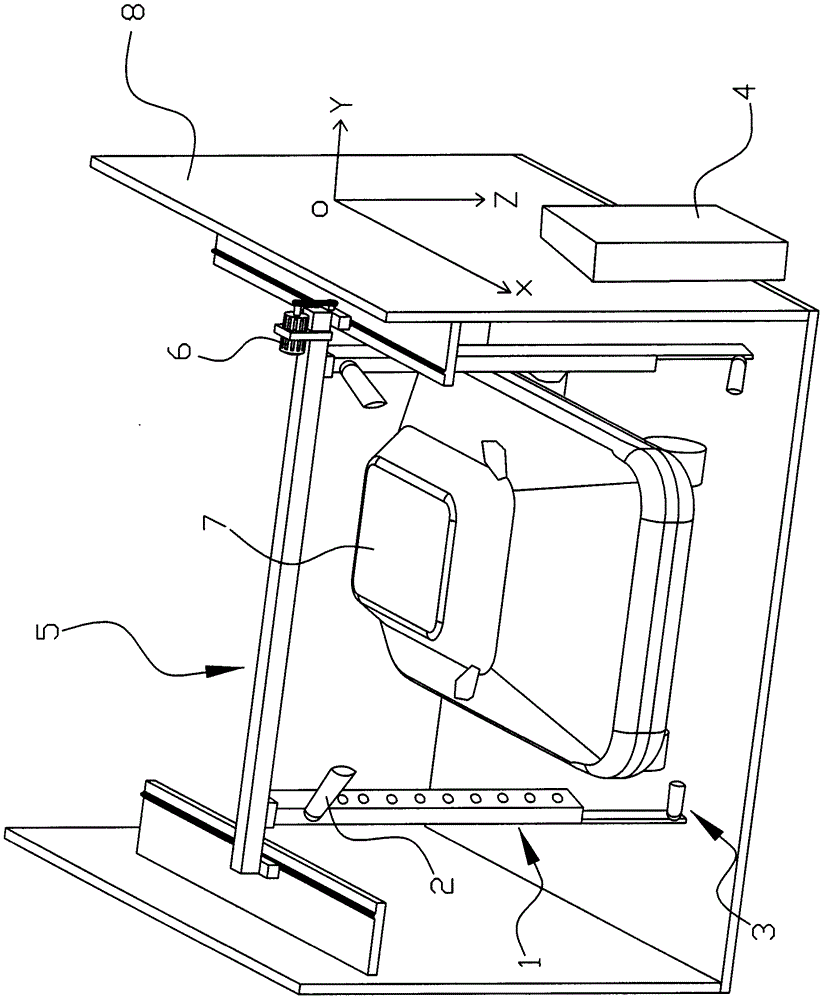

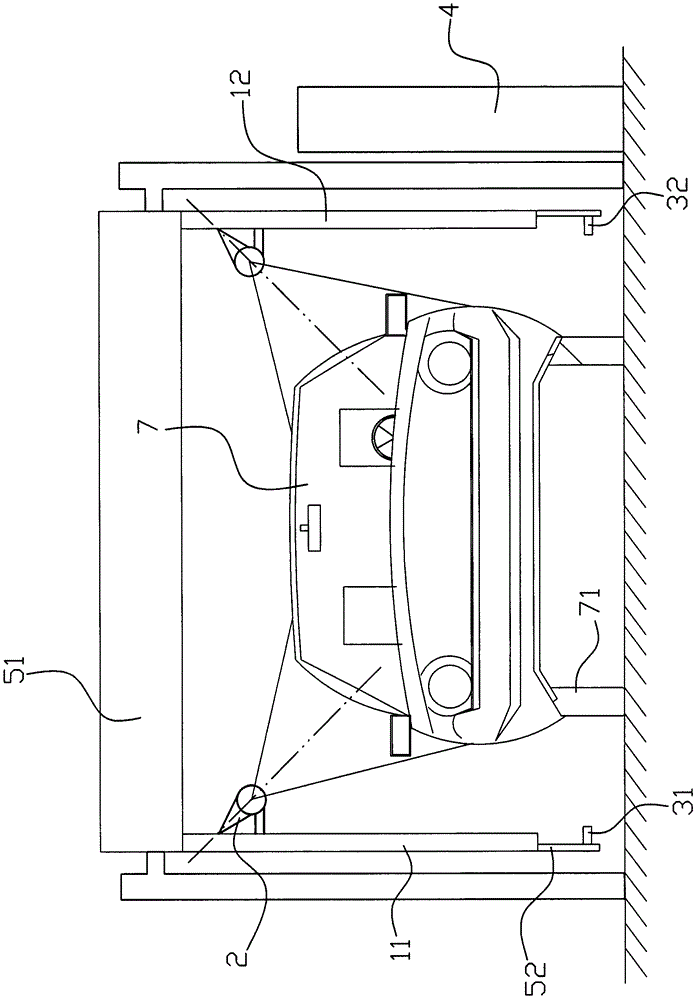

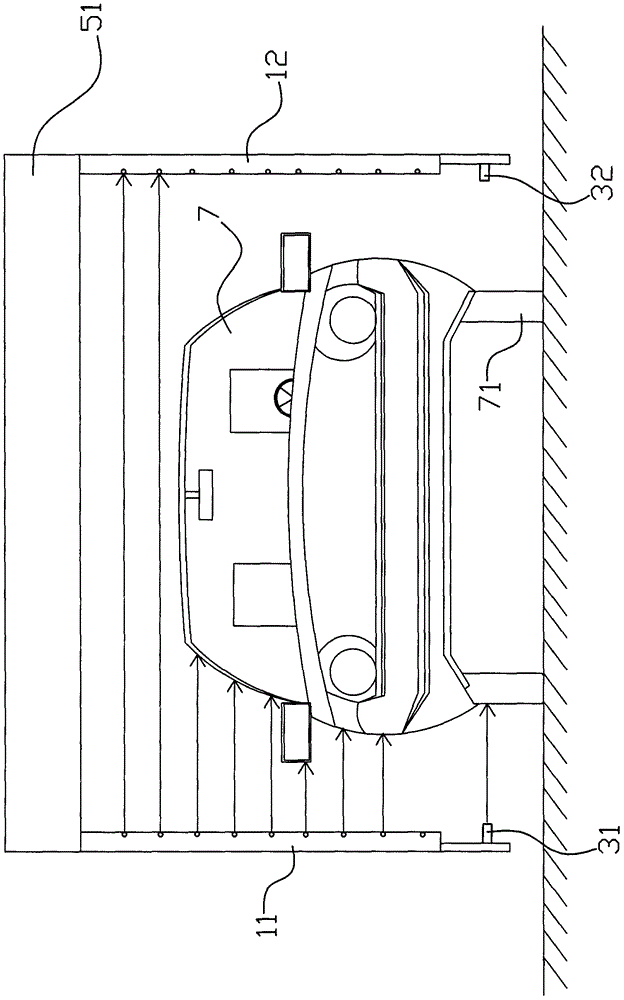

[0019] Such as Figure 1 to Figure 4 As shown, the vehicle body position detection method for car washing in this embodiment, the vehicle body position detection method is composed of the following steps: measuring the height of the vehicle body by the measuring device 1, measuring the position of the tire 71 by the detector 3, and measuring the contour of the vehicle body by the image processor line, the measuring device 1, the detector 3 and the image processor are respectively connected to the electrical control module 4 through lines, and the measuring device 1, the detector 3 and the camera 2 in the image processor are fixed on the frame body 5, and the frame body 5 Can be placed on the car washing rack 8 by the driving mechanism, which is connected to the electric control module 4;

[0020] Above-mentioned measurer 1 comprises transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com