A high-sensitivity resonant system based on straight waveguide-feedback waveguide-ring-straight waveguide

A high-sensitivity, resonant system technology, applied in the optical field, can solve the problems of insufficient measurement accuracy of fiber resonators, and achieve the effects of reducing the required space, high sensitivity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

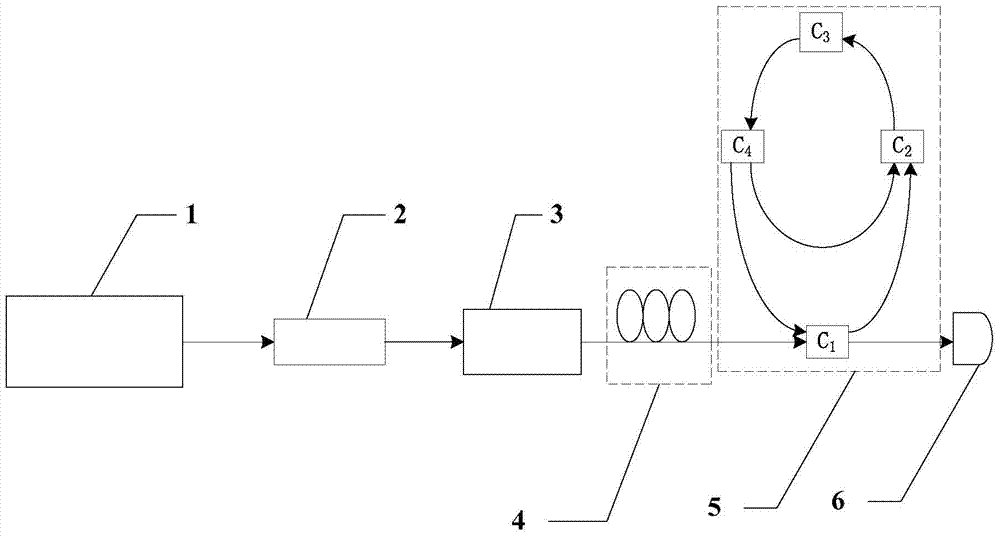

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a high-sensitivity resonant system based on straight waveguide-feedback waveguide-ring-straight waveguide described in this embodiment, which includes a laser 1, an attenuator 2, an isolator 3, a polarization controller 4, and a resonant structure 5 and a detector 6, the transmitting end of the laser 1 is connected to the input end of the attenuator 2, the output end of the attenuator 2 is connected to the input end of the isolator 3, and the output end of the isolator 3 is connected to the input end of the resonant structure 5, A polarization controller 4 is arranged on the optical fiber between the output end of the isolator 3 and the input end of the resonant structure 5, and the output end of the resonant structure 5 is connected to the receiving end of the detector 6;

[0017] The resonant structure 5 includes a first coupler C 1 , the second coupler C 2 , the third coupler C 3 and the ...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1Describe this embodiment. This embodiment is a further limitation of a high-sensitivity resonant system based on straight waveguide-feedback waveguide-ring-straight waveguide described in Embodiment 1. All optical fibers are SMF-28 single-mode optical fibers .

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further definition of a high-sensitivity resonant system based on straight waveguide-feedback waveguide-ring-straight waveguide described in Embodiment 1. The optical fiber in the ring resonator and feedback waveguide The overall length ratio is L 反 / L 环 = 1.6 or L 反 / L 环 =1.4,L 反 is the total length of the fiber in the feedback waveguide, L 环 is the total length of the fiber in the ring resonator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com