Angle measurement method and device based on alternate complementary work of double-rate integrating gyroscope

An angle measurement device and angle measurement technology, which are applied in the direction of measurement device, measurement angle, surveying and navigation, etc., can solve the problem of inability to guarantee measurement accuracy, and achieve the effect of avoiding short working time, high measurement accuracy and large dynamic range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

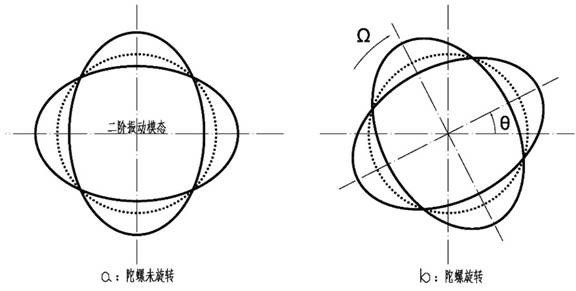

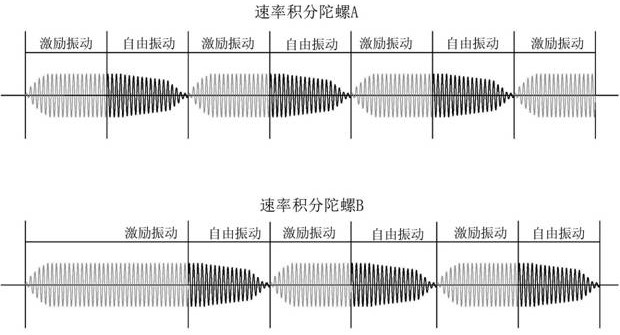

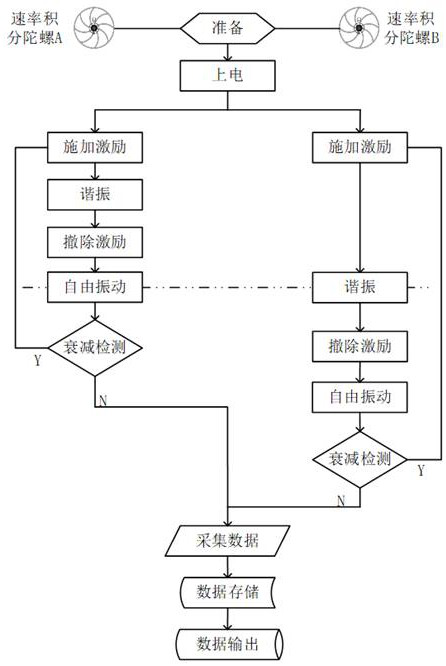

[0019] see figure 2 , this embodiment is based on the angle measurement method of dual-rate integrating gyroscopes working alternately and complementaryly, including driving and controlling a pair of rate-integrating gyroscopes A ( figure 2 denoted as A gyro), rate-integrating gyro B ( figure 2 (referred to as B gyro) work alternately and complementary, so that the rate-integrating gyro A is alternately in the excited vibration state and the free vibration state, and when the rate-integrating gyro A is in the excited vibration state, the rate-integrating gyro B is in the free-vibration state, and the rate-integrating gyro A is in the In the free vibration state, the rate-integrating gyro B is in the excitation vibration state, and the signal of the rate-integrating gyro A or rate-integrating gyro B in the current free vibration state is selected as the detection signal. The rate-integrating gyroscope is a gyroscope designed, processed, and manufactured using MEMS technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com