Microminiature machining cutting force real-time wireless detection and control system

A machining and control system technology, which is applied in the field of real-time detection and control of cutting force, real-time wireless detection and control system of cutting force in micro-machining, and can solve problems such as large application limitations, cable winding, and large cutting force. Achieve the effect of improving machining accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

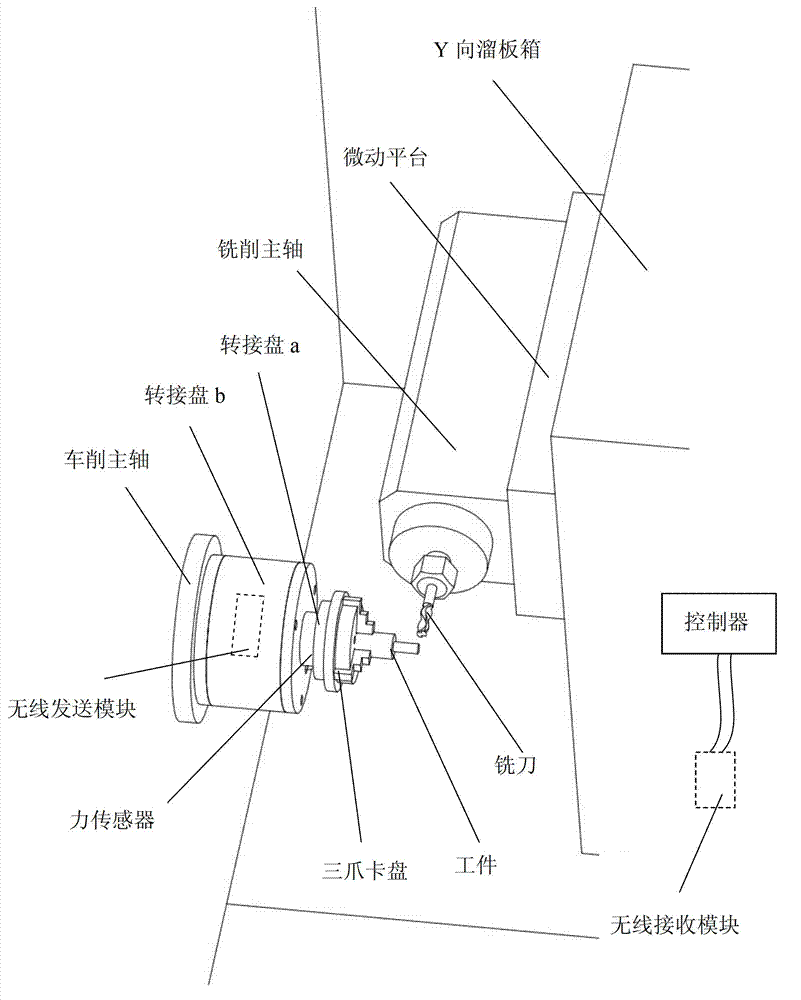

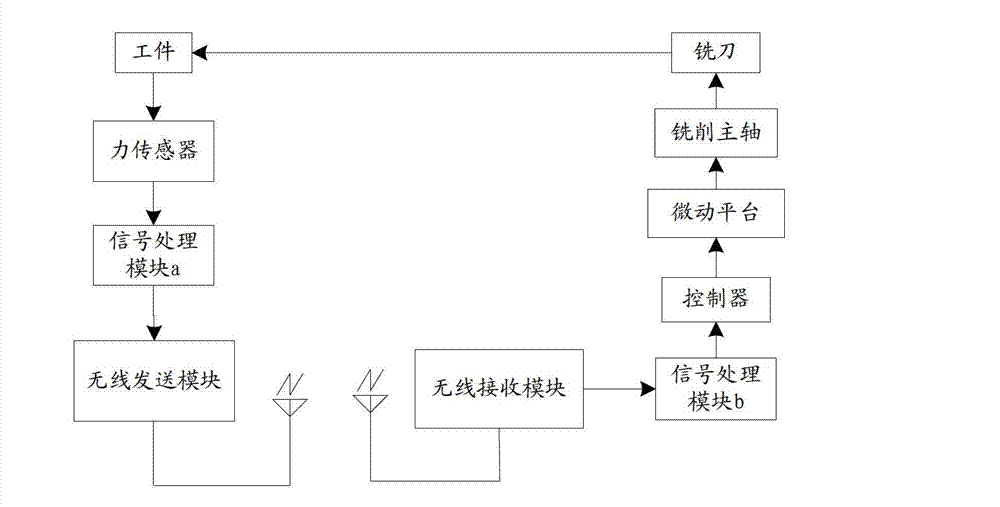

[0014] as attached figure 1 and attached figure 2 As shown, the present invention provides a real-time wireless detection and control system for micro machining cutting force, the detection and control system includes a six-dimensional force sensor, adapter plate a, adapter plate b, signal processing module a, wireless transmission Module, wireless receiving module, signal processing module b, controller and micro-motion platform; the six-dimensional force sensor is a ring structure; the transfer plate b is a cylindrical cavity structure, and the two ends of the transfer plate b are provided with end caps .

[0015] Installation relationship: the end cover at one end of the adapter plate b is fixedly connected to the end face of the turning spindle, the end cover at the other end of the adapter plate b is fixedly connected to one end face of the force s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com