Portable train wheel normal section contour structured light vision measurement system and method

A technology of train wheel and contour structure, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of incomplete measured contour, low efficiency, influence of measurement accuracy and installation accuracy, etc., and achieve the effect of improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

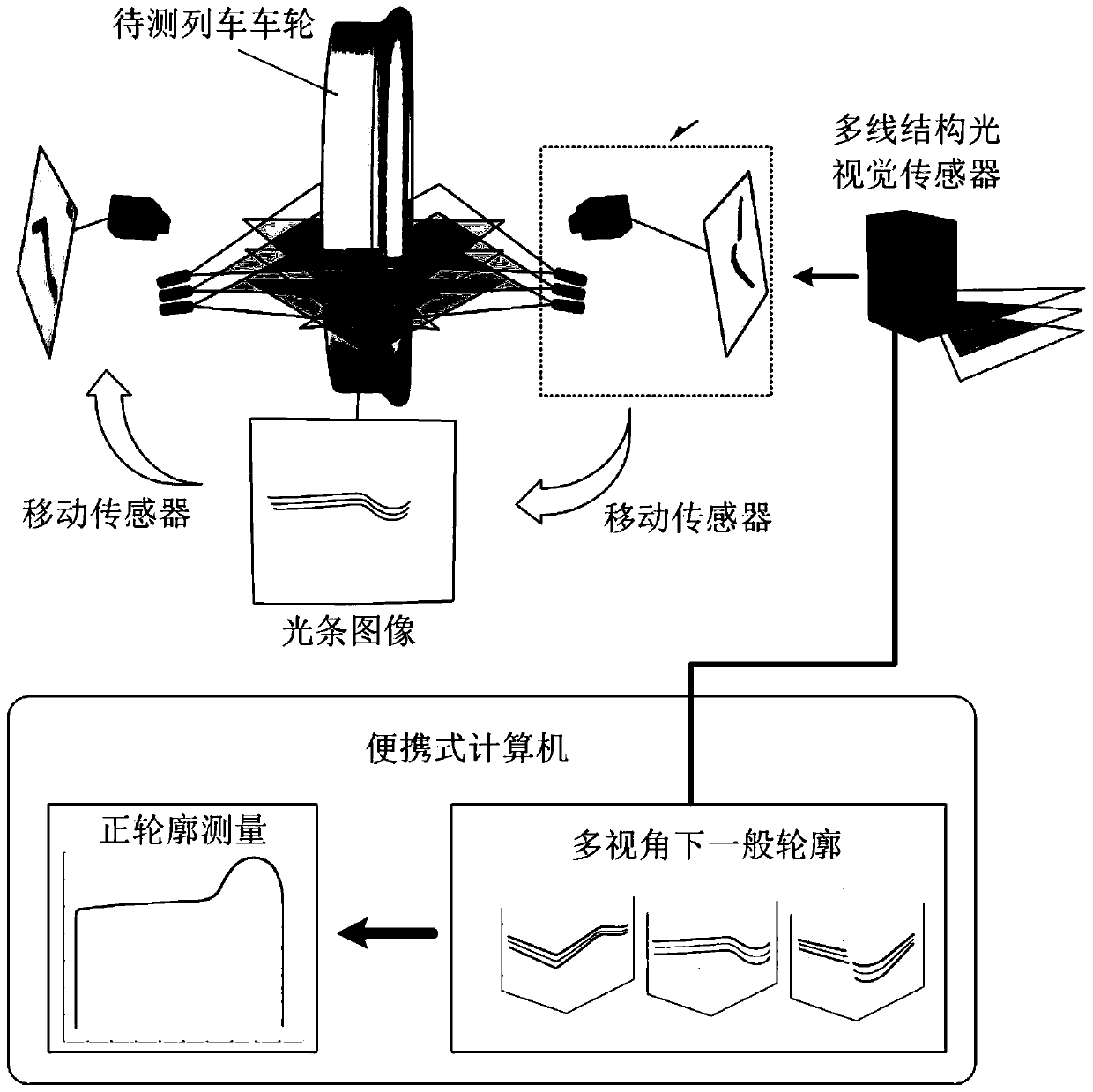

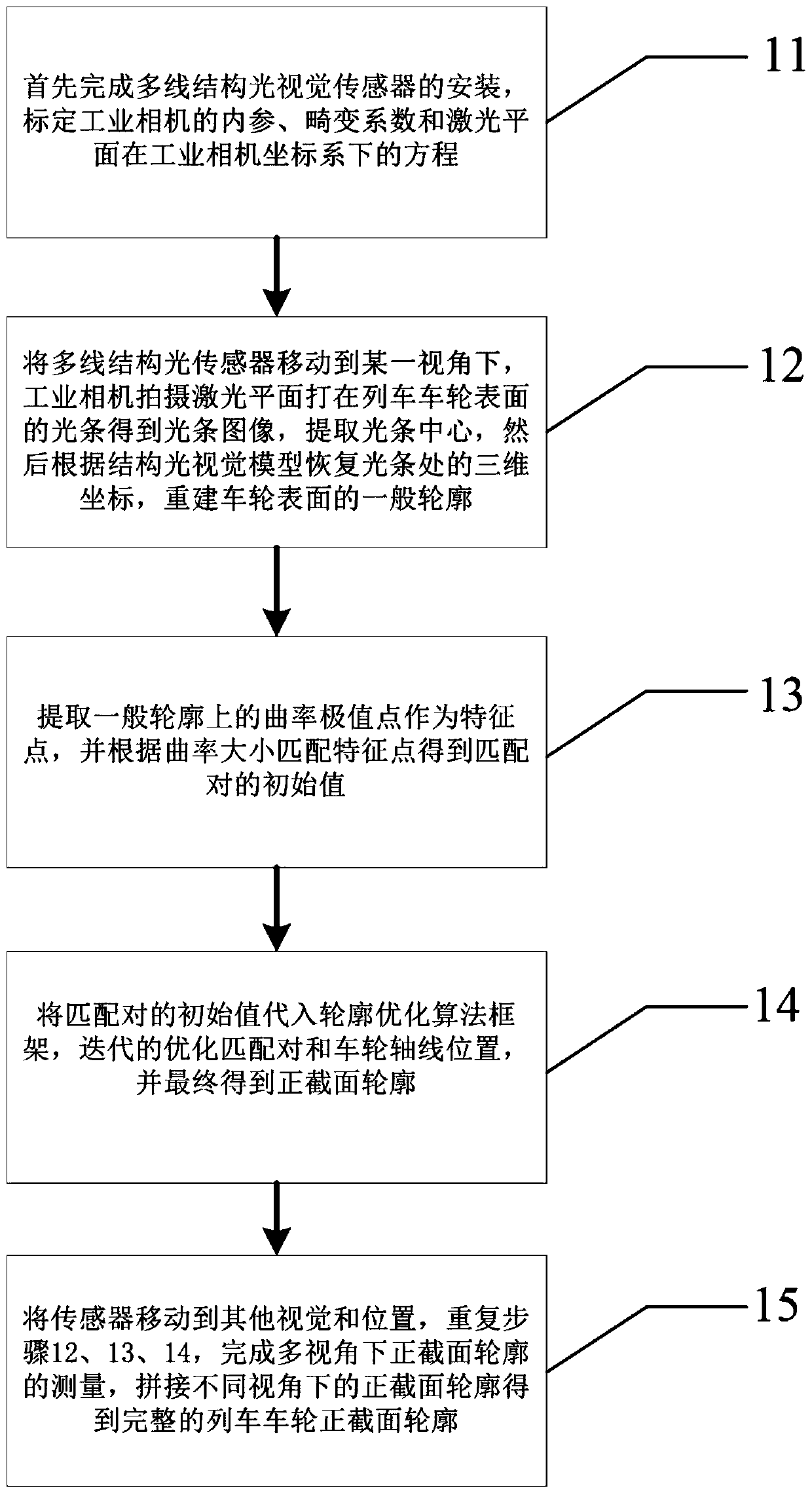

[0050] figure 1 and figure 2 They are respectively the overall realization flow chart of a portable structured light vision measurement system and method for the front cross-sectional profile of a train wheel according to the present invention. The structured light vision measurement system for the profile of the front section of the train wheel is composed of a multi-line structured light vision sensor, a portable computer, and measurement control software. It can move freely to different viewing angles and reconstruct the general profile of the train wheel under multiple viewing angles. The structured light visual measurement method of the front section profile of the wheel recovers the front section profile of the train wheel from the general profile of the train wheel surface, and obtains a complete front section profile by spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com