Diffractive optical chip

A diffractive optics and chip technology, applied in diffraction gratings and other directions, can solve the problems of large surface shape combination, weakened energy of coated Gaussian mirror, complex aspheric surface shaping, etc., and achieves high device reliability, high integration and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

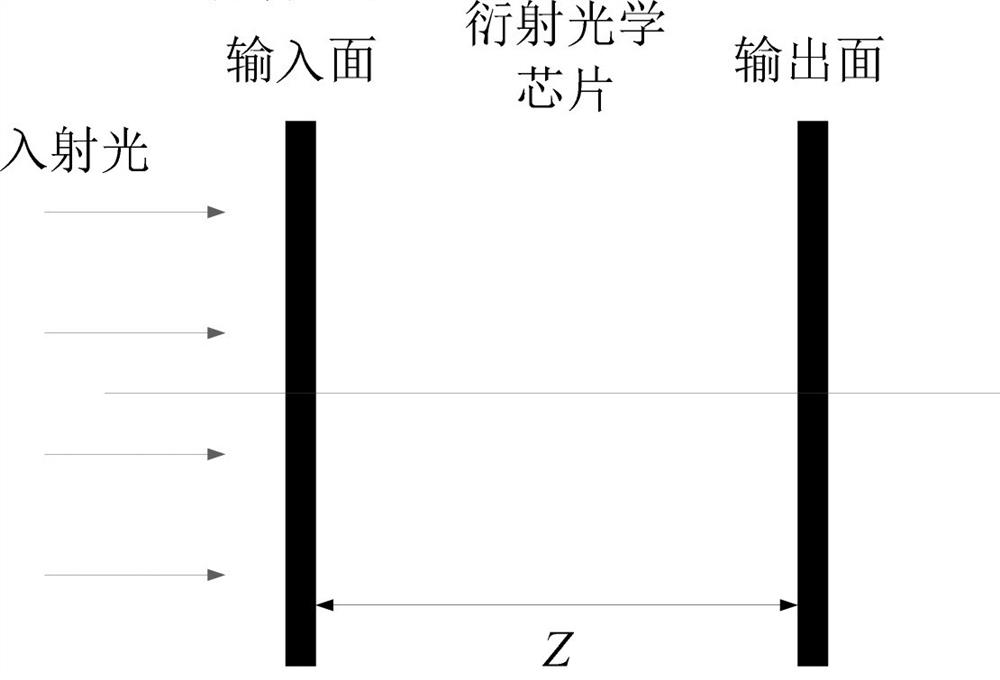

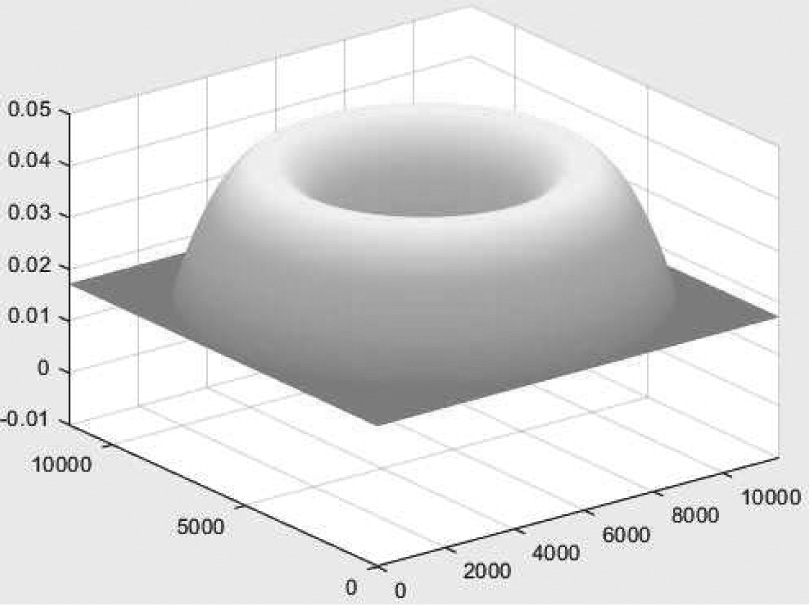

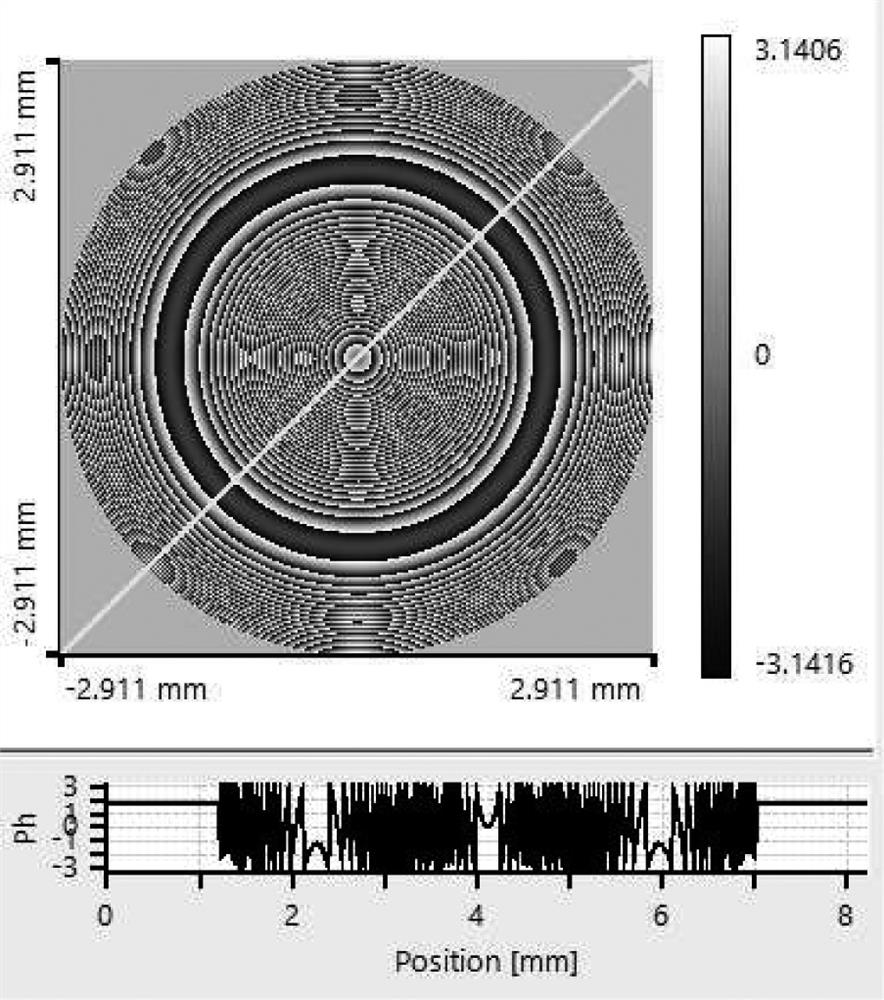

[0042] refer to figure 1 As shown, a diffractive optical chip disclosed in the present invention has an incident surface for intensity homogenization and an exit surface for phase homogenization, the micro-nano structures on the incident surface and the exit surface are centrosymmetric structures, The output surface can be round or square, or other shapes can be determined according to actual needs. The area of the micro-nano structure on both sides can be made according to the diameter of the light source after collimation. The structure area of the incident surface on the left side of this embodiment is 5.8 μm 2 ~20mm 2 , the structural area of the exit surface on the right is 3.8 μm 2 ~ 20mm 2 , not limited to this area, the production area can be increased according to the needs, and the micro-nano structure area of the two surfaces can be equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com