Method for producing thin-wall metal circular ring and grading stamping mould used therefor

A metal ring and stamping die technology, applied in the field of stamping dies, can solve the problems of low machining accuracy and low production efficiency of metal rings, and achieve the effects of high concentricity, improved production efficiency and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

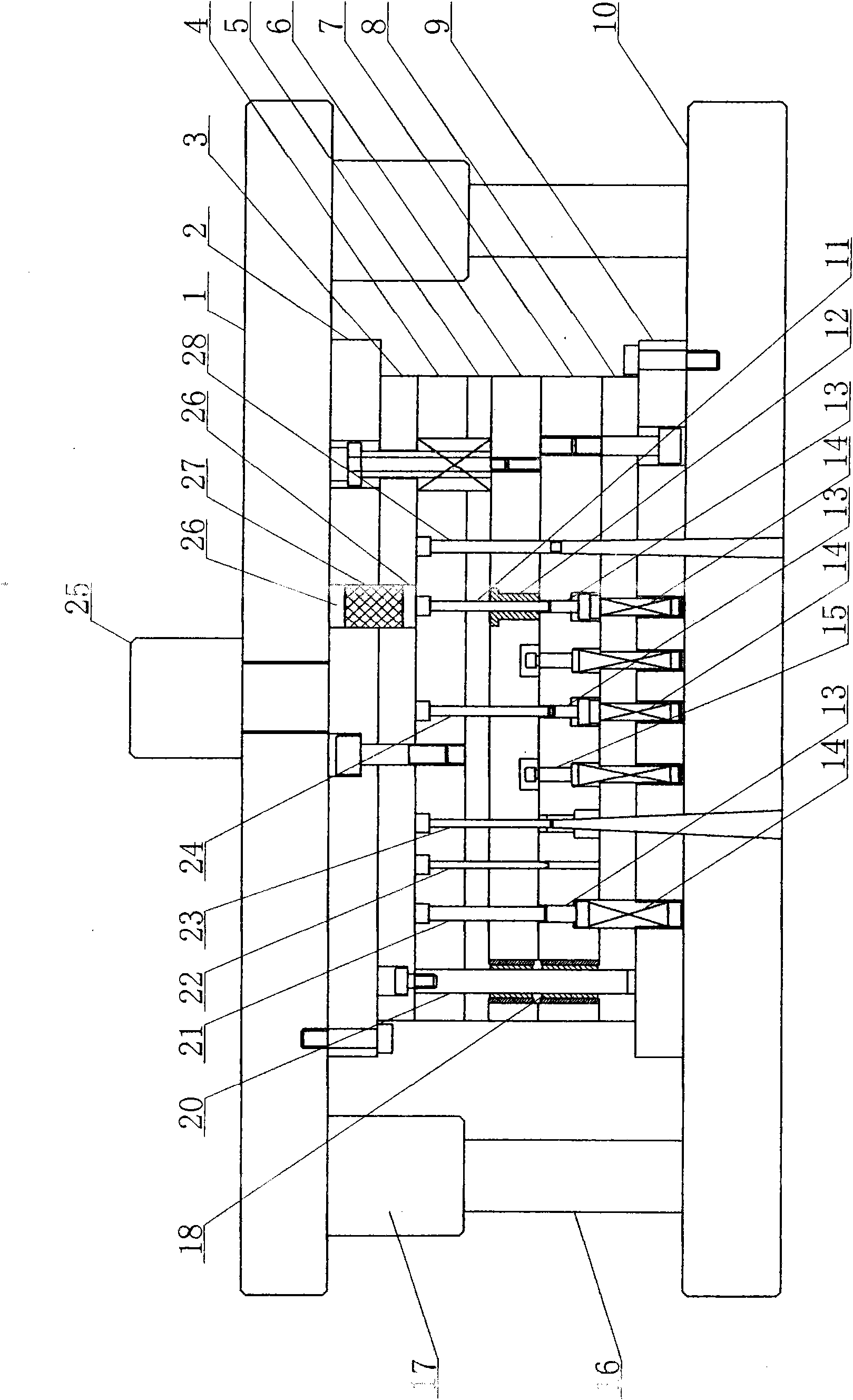

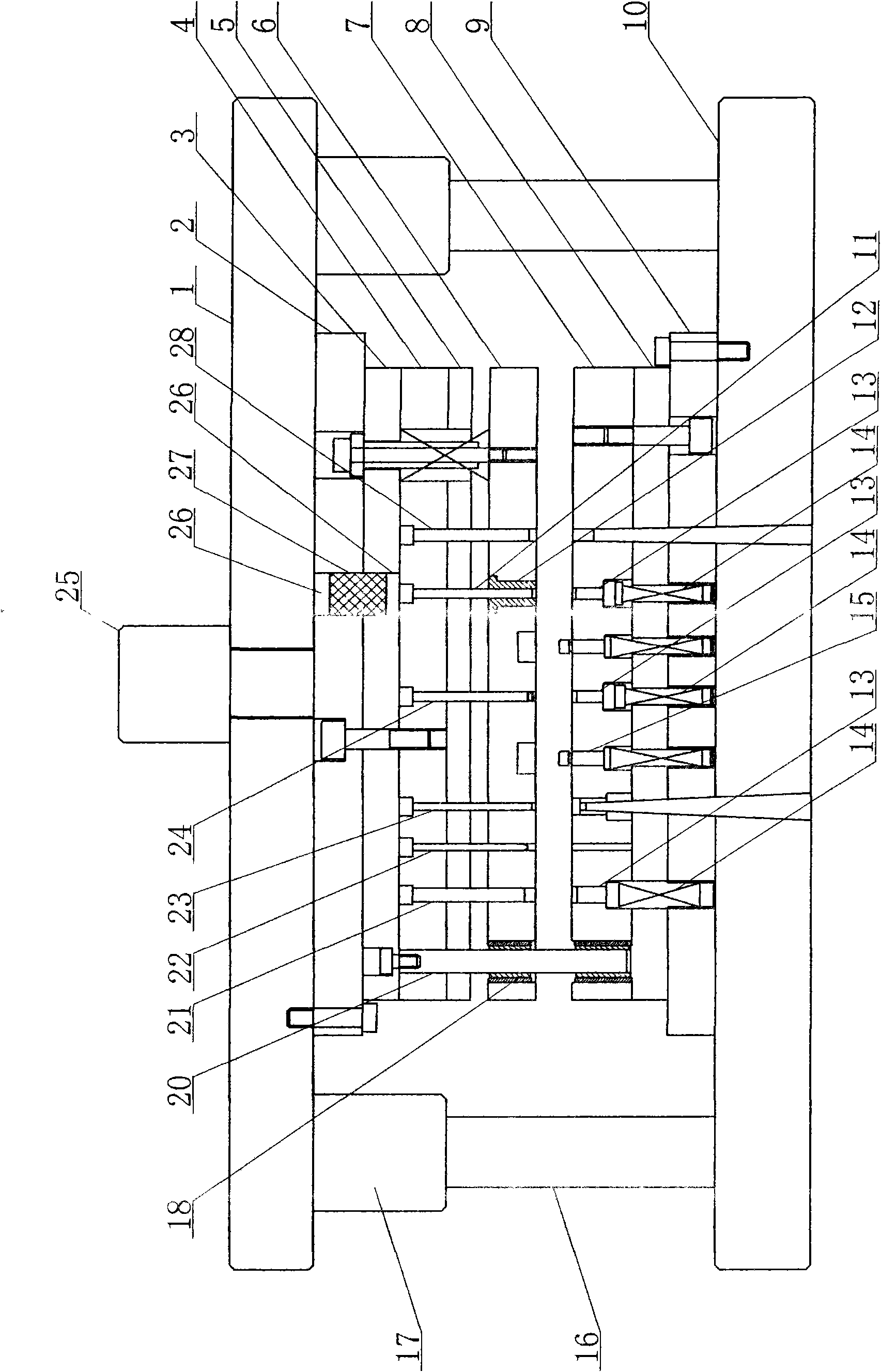

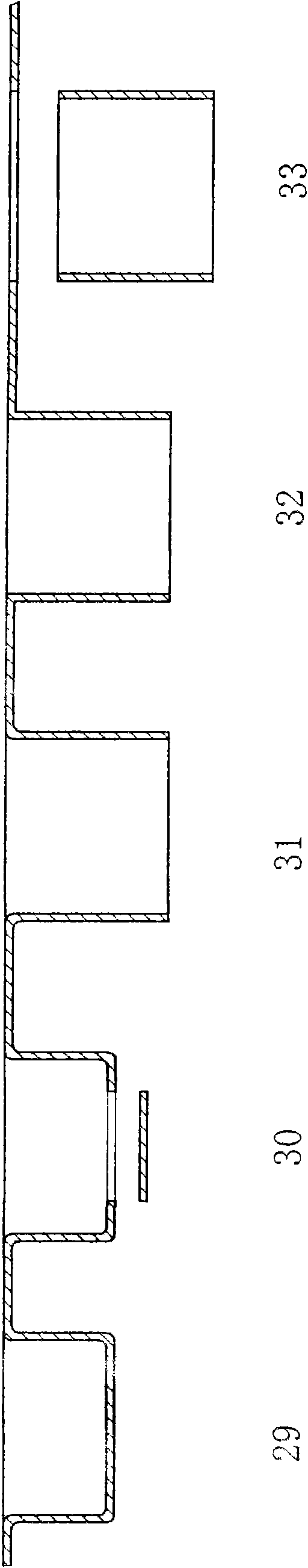

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a method for producing a thin-walled metal ring, placing the plate or strip in a progressive stamping die, includes the following steps in sequence: drawing step 29, drawing the plate or strip into an open top A cylinder with a closed bottom; punching step 30, punching a round hole at the bottom of the cylinder; flanging step 31, turning the circular edge of the bottom of the cylinder outward; shaping step 32, placing the cylinder on The progressive stamping die is in an annular closed cavity formed when the mold is closed, and then applies pressure to the annular area of the connection between the top of the cylinder and the plate or strip material; blanking step 33, the cylinder is moved from the cylinder along the outer peripheral surface of the cylinder Separation on sheet or strip. The ring-shaped closed cavity is formed by the following steps: First, the shaping punch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com