Process for producing components having regions of differing ductility

a technology of ductility and production process, applied in the direction of quenching device, furnace type, shaping tool, etc., can solve the problems of high stress on spot-welded connections, affecting the quality of sheet steel components, and requiring expensive sealing treatment to control them. , to achieve the effect of sufficient cathodic corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The invention offers several process options.

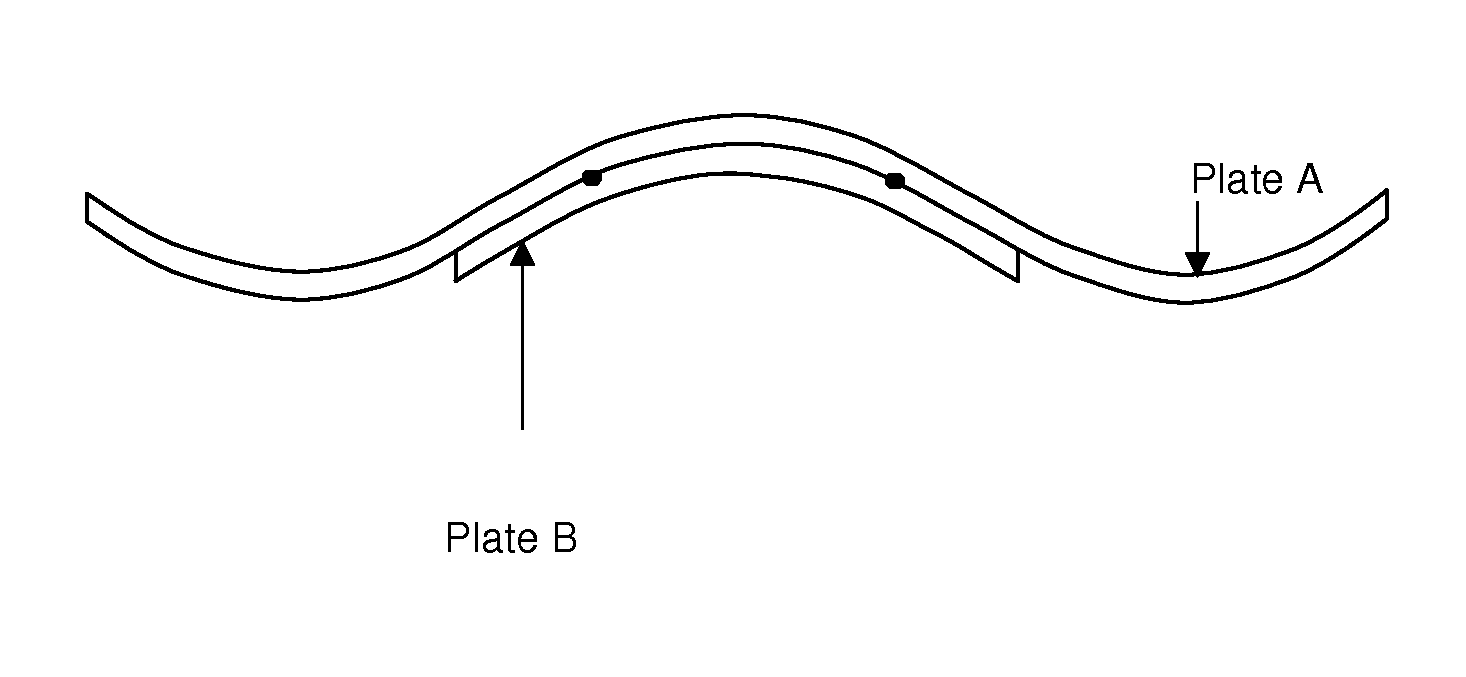

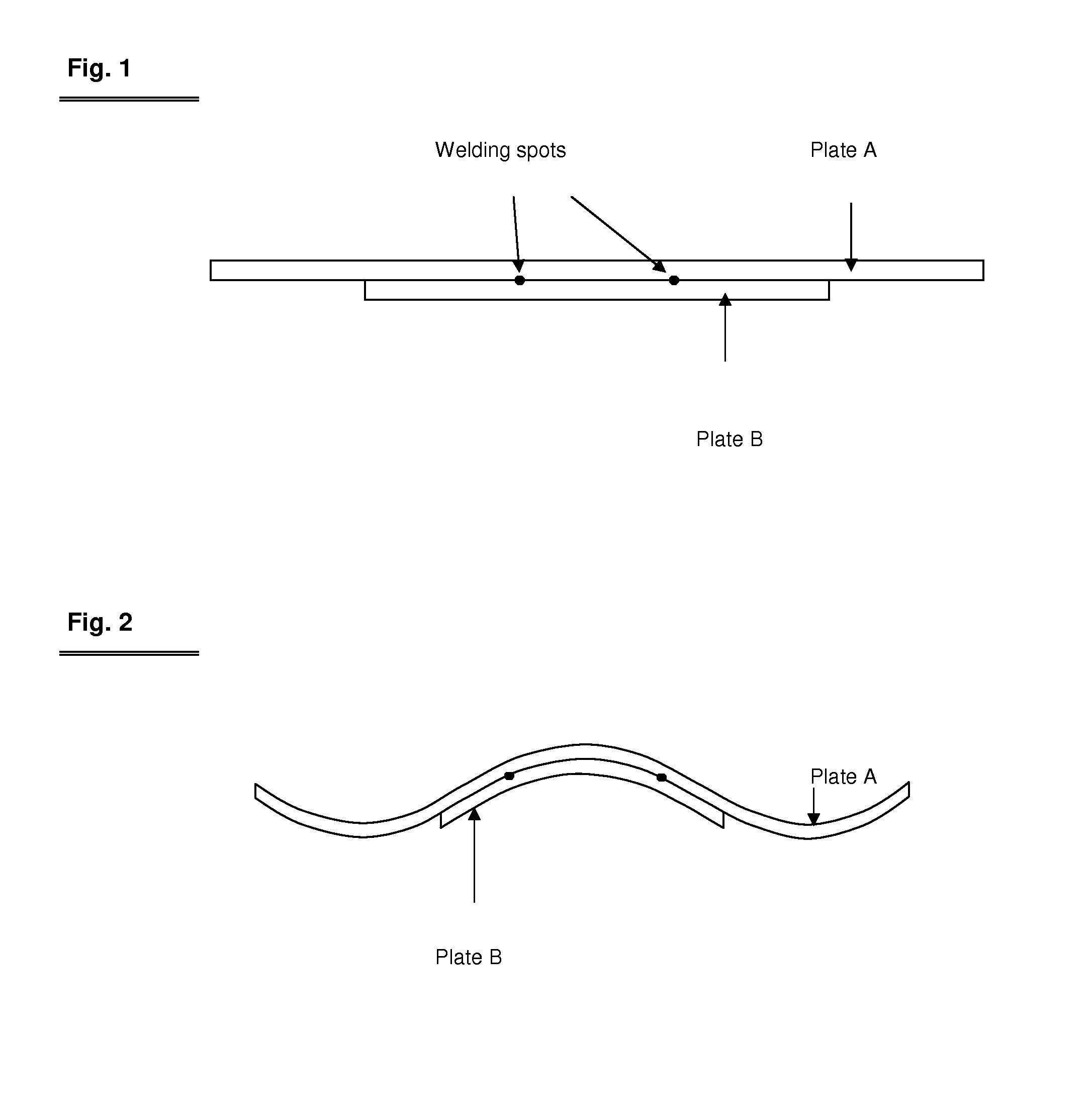

[0028]In process option 1, the cold-produced component (FIG. 2) composed of the joined individual plates A and B is heated in the furnace at approx. 900° C. until the larger component A has reached the austenitizing temperature in the regions in which it is not resting against the smaller component B.

[0029]In the regions in which components A and B are joined, the component has a higher mass to be heated.

[0030]This makes it possible, with the same furnace residence time, for region B of the component to not reach the austenitizing temperature while region A is heated to the austenitizing temperature due to its single sheet thickness and therefore lower mass.

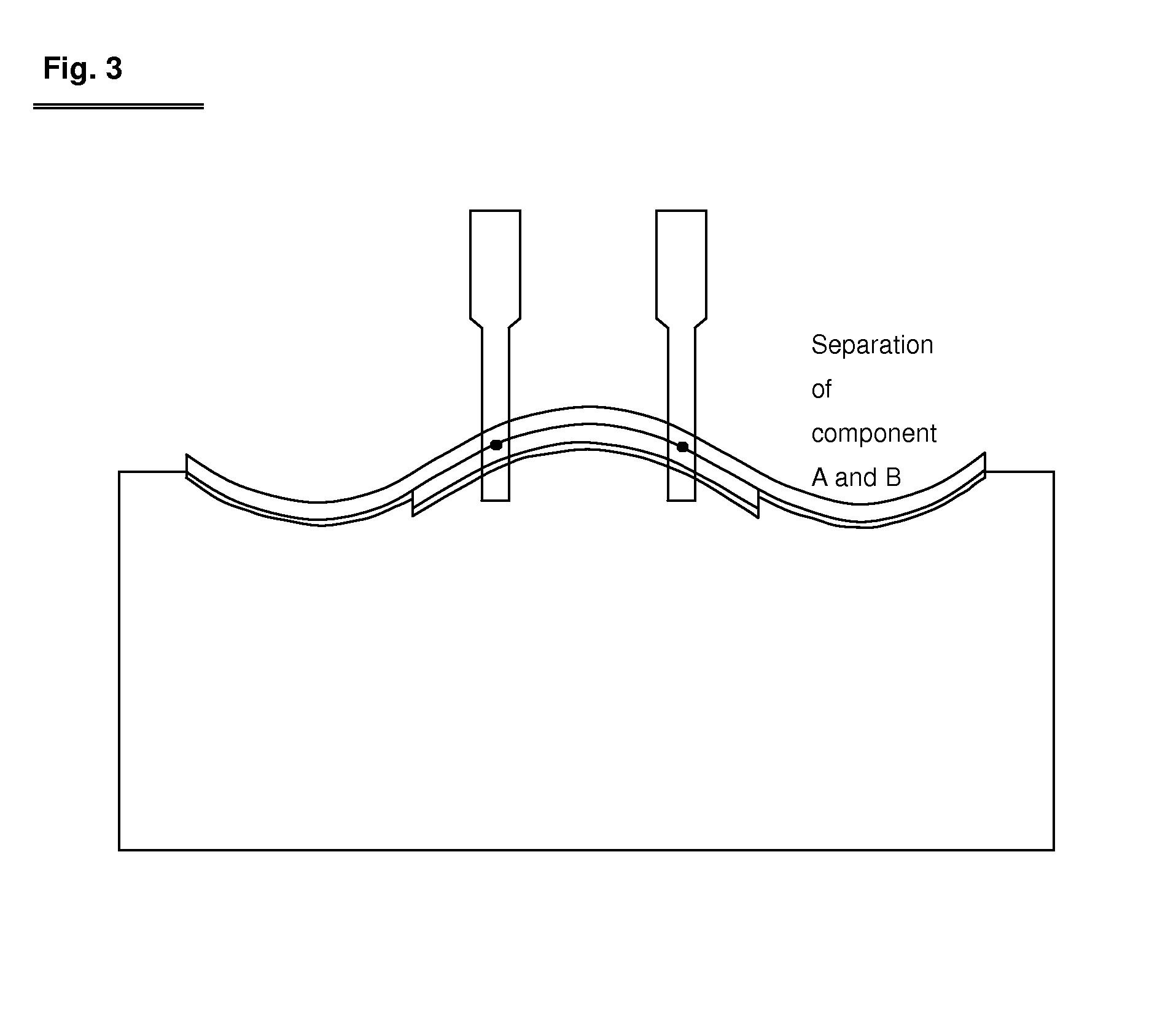

[0031]The component is then cooled and press hardened in a press hardening die.

[0032]After the press hardening, the component has a more ductile material structure in region B because it did not reach the austenitizing temperature in the furnace.

[0033]Depending on the selected fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| austenitizing temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com