Transfer method, method of manufacturing thin film devices, method of maufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

a technology of thin film devices and transfer methods, applied in the direction of non-linear optics, instruments, semiconductor/solid-state device details, etc., can solve the problems of inability to withstand such high temperatures, difficult to accurately align, and uncertainty in the placement of microstructures on the substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0119]FIGS. 4A to 12B are drawings for explaining a first embodiment (transfer method) of the present invention. The first embodiment comes under the first invention, which relates to carrying out partial transfer once. The device transfer method is carried out through the following first to fifth steps.

[0120] In the first step, as shown in FIG. 4A, a peeling layer (light-absorbing layer) 11 is formed on a first substrate (transfer origin substrate) 10.

[0121] The first substrate 10 is preferably a light-transmitting substrate through which light can pass. As a result, light can be irradiated onto the peeling layer via the first substrate, and hence peeling can be made to occur swiftly and accurately through the irradiation of light onto the peeling layer. In this case, it is preferable for the transmissivity to light of the first substrate to be at least 10%, more preferably at least 50%. The higher the transmissivity, the lower the attenuation (loss) of light becomes, and hence t...

second embodiment

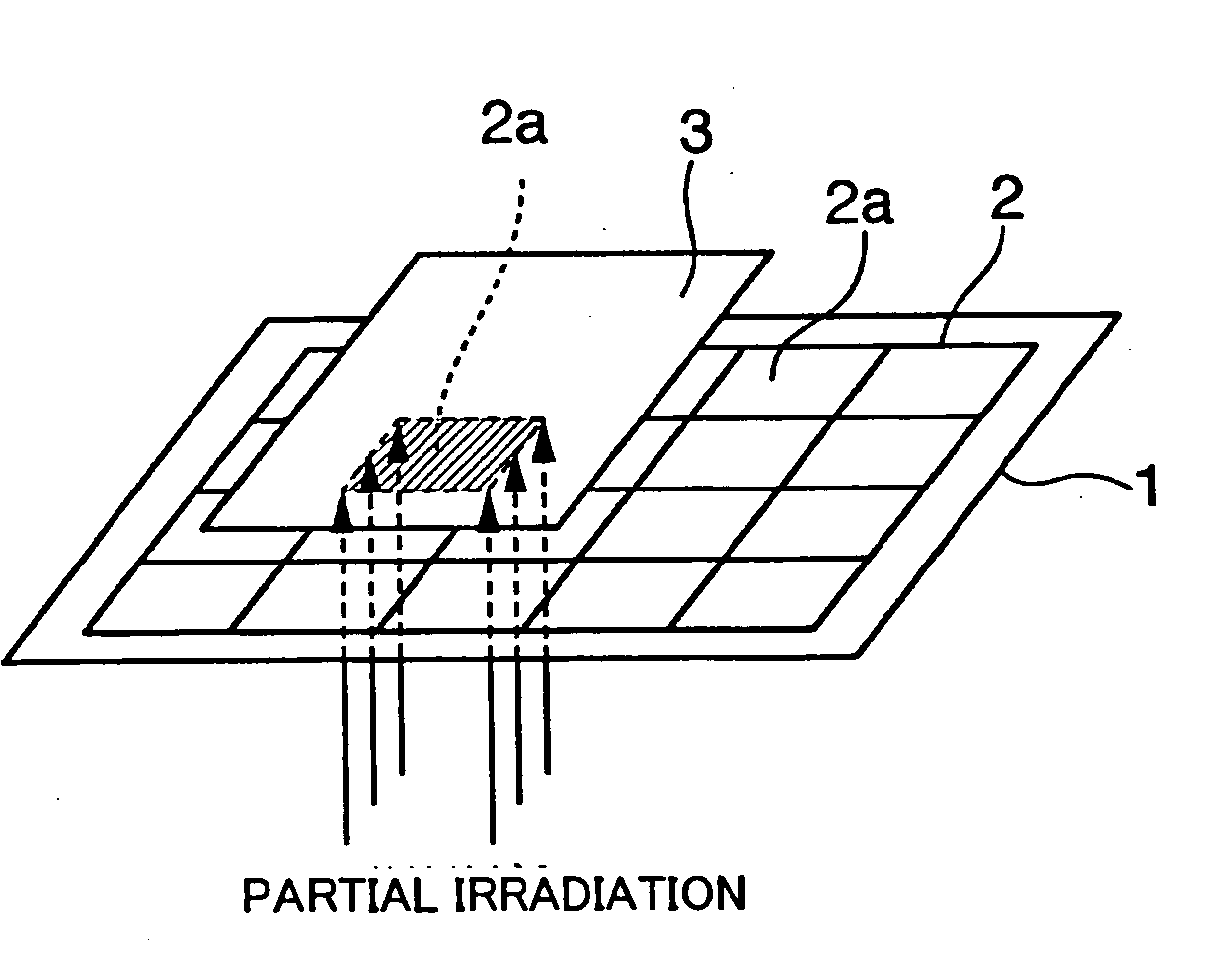

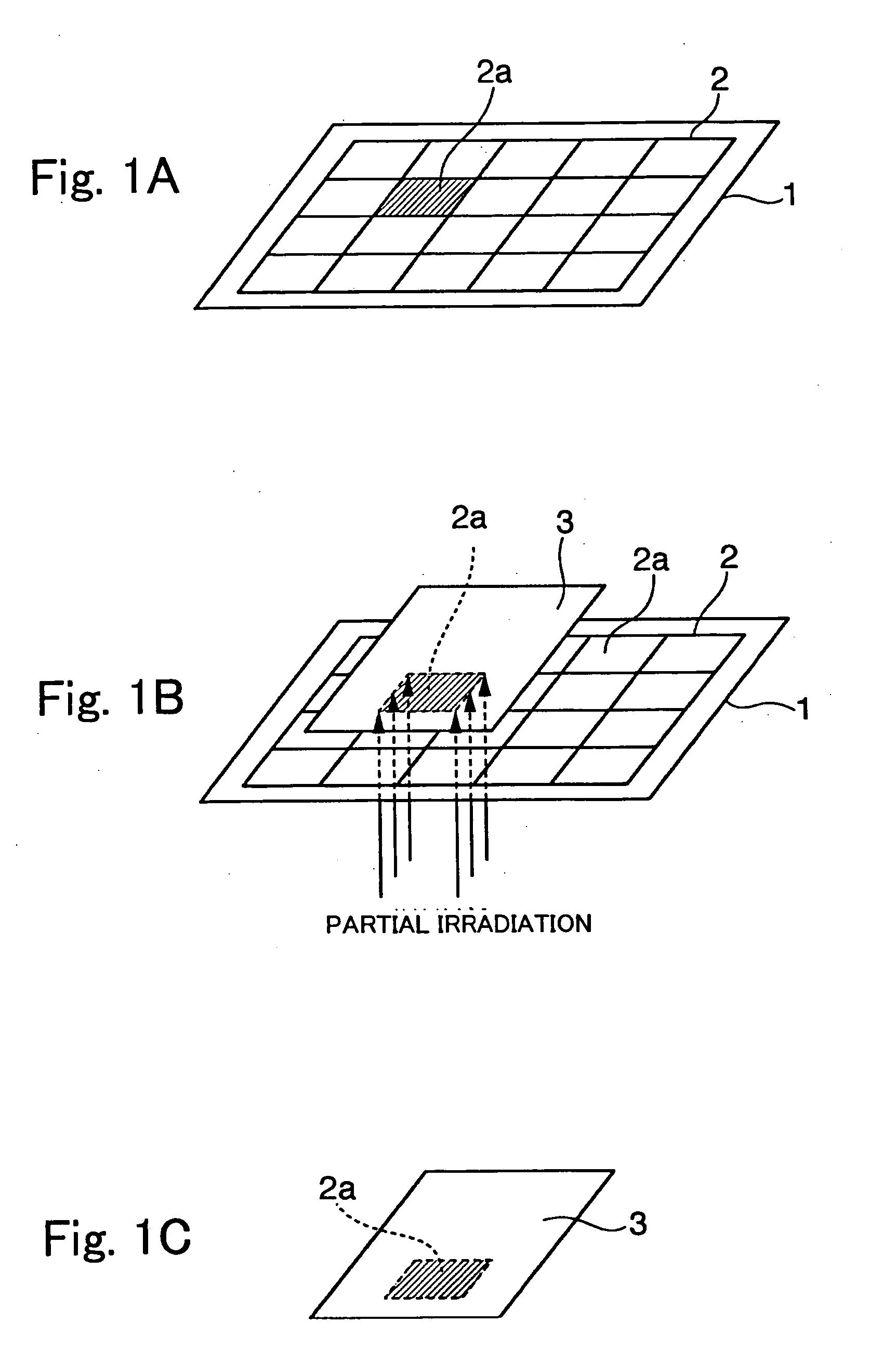

[0222]FIGS. 13A to 13D are drawings for explaining a second embodiment (transfer method) of the present invention. As with the first embodiment described above, the present second embodiment comes under the first invention, which relates to carrying out partial transfer once, but the present second embodiment differs from the first embodiment in particular in that, in the third step, the transferred bodies 12a to be transferred are joined to the final substrate 14 through a combination of a UV-curing resin and partial irradiation with UV light.

[0223] The first step and the second step can be carried out as in the first embodiment described above with regard to the methods of operation, components and materials used, formation conditions and so on, and hence the description of these steps will be omitted here.

[0224] In this second embodiment, a first substrate 10 having a large number of transferred bodies 12a formed thereon, and a final substrate 14 having an adhesive layer 52 com...

third embodiment

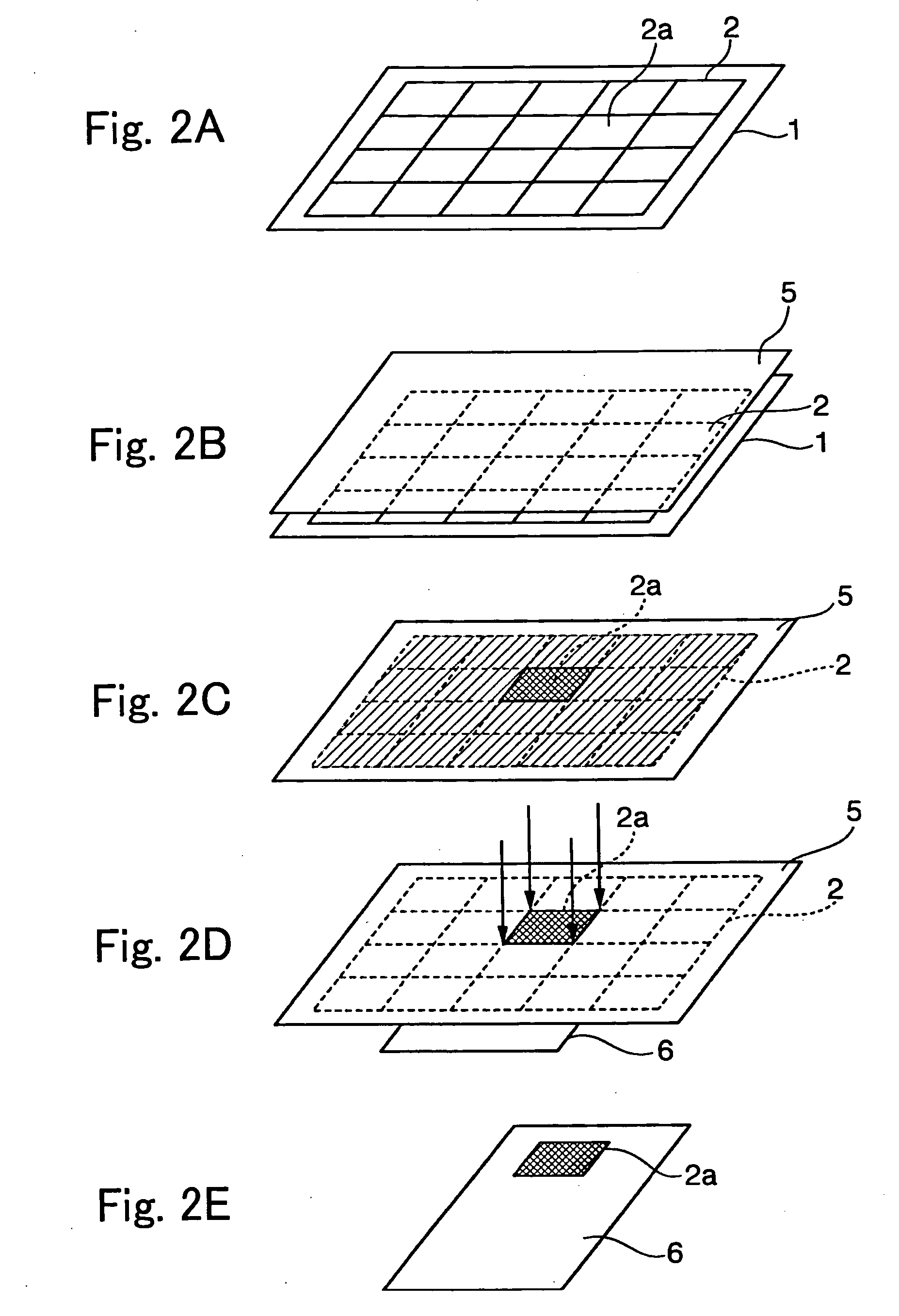

[0233]FIGS. 14A and 14B are drawings for explaining a third embodiment (transfer method) of the present invention. As with the first embodiment described above, the present third embodiment comes under the first invention, which relates to carrying out partial transfer once, but the present third embodiment differs from the first embodiment in particular in that, in the third step, the transferred bodies 12a to be transferred are joined to the final substrate 14 through a combination of an adhesive sheet 56 comprising a heat-fusing adhesive disposed between the final substrate 14 and the transferred bodies 12a and partial irradiation with laser light L1.

[0234] The first step and the second step can be carried out as in the first embodiment described above with regard to the methods of operation, components and materials used, formation conditions and so on, and hence the description of these steps will be omitted here.

[0235] In this third embodiment, adhesive (heat-fusing) sheets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com