Water-Cooled Oil-Free Air Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

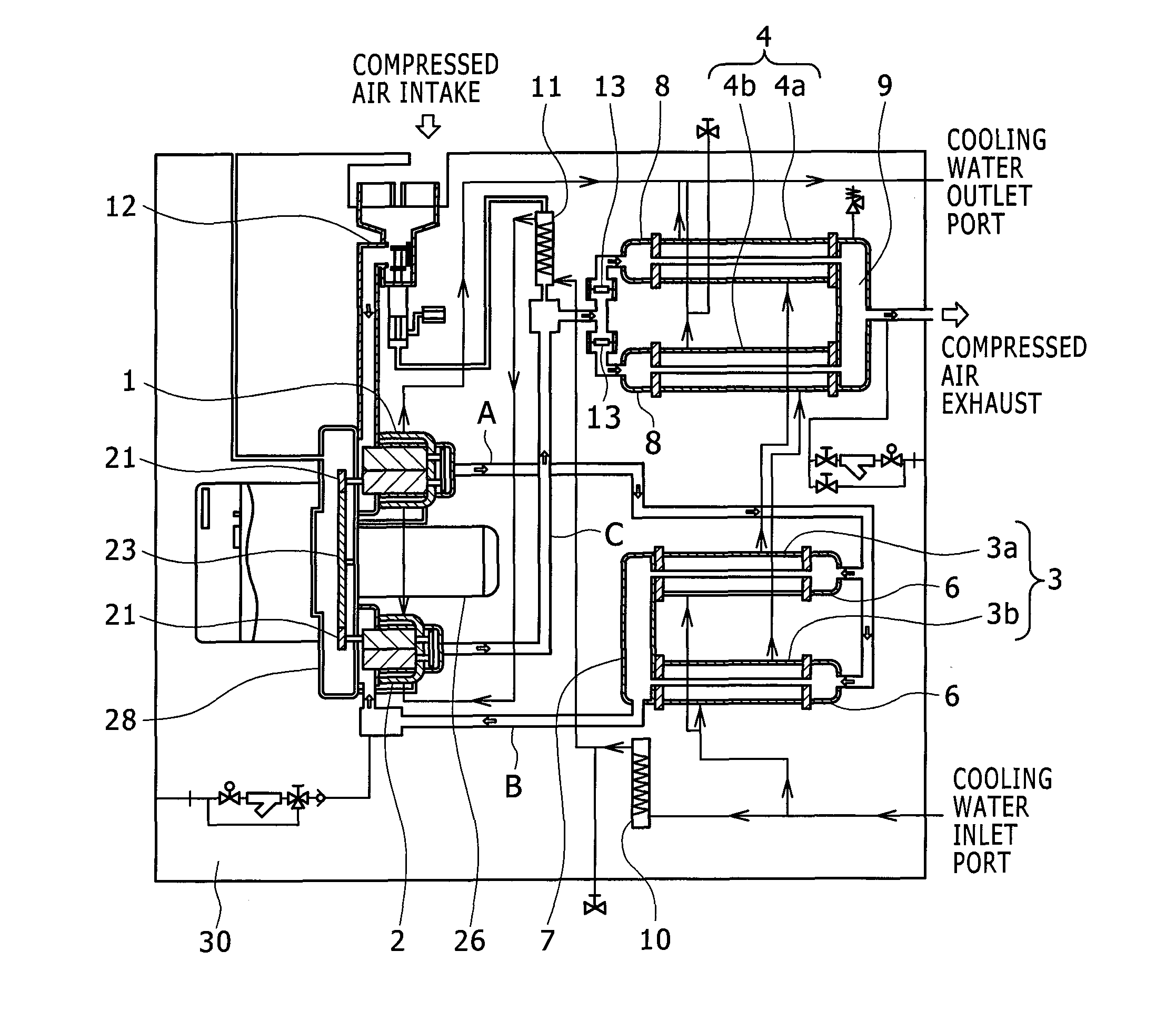

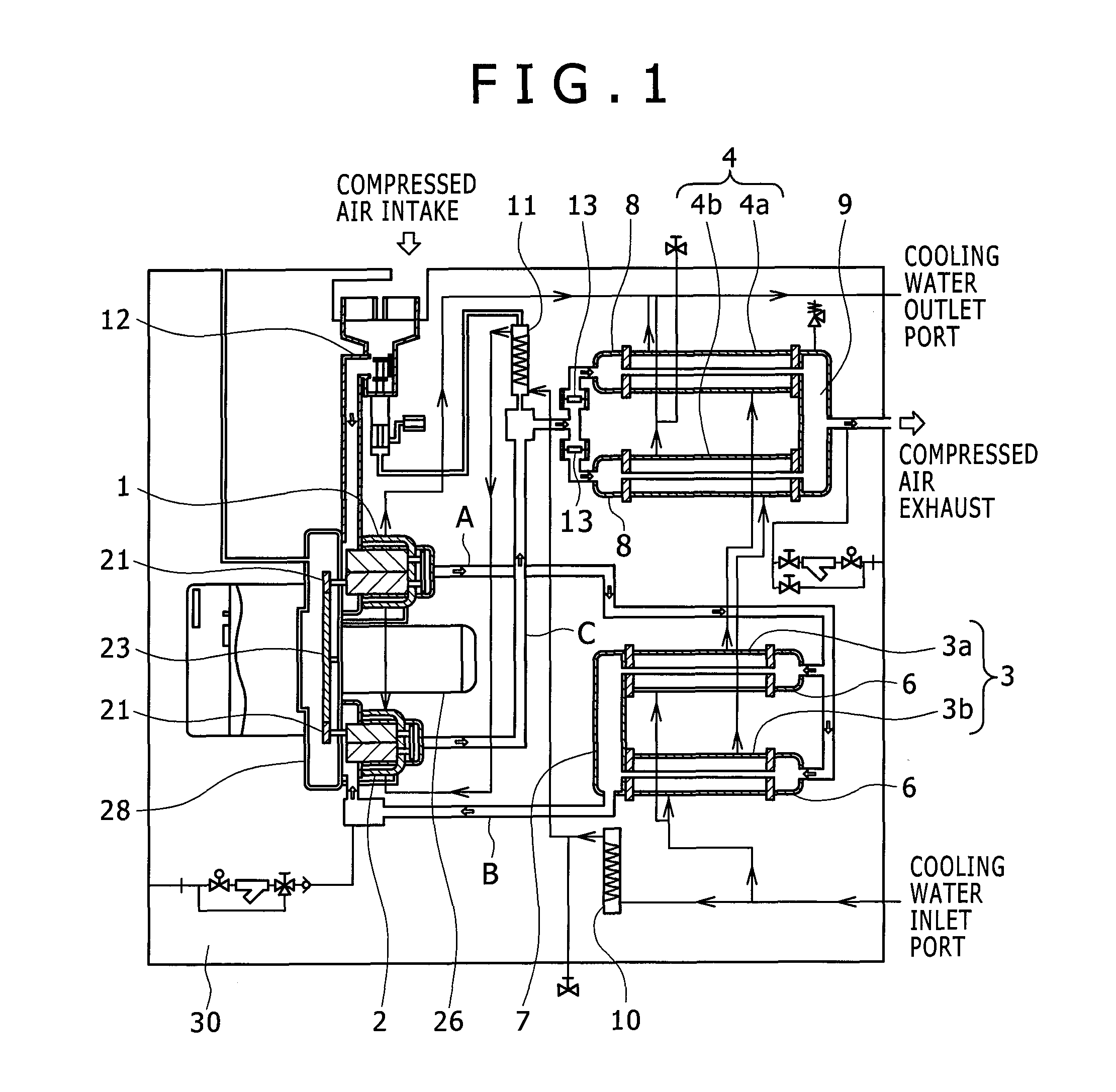

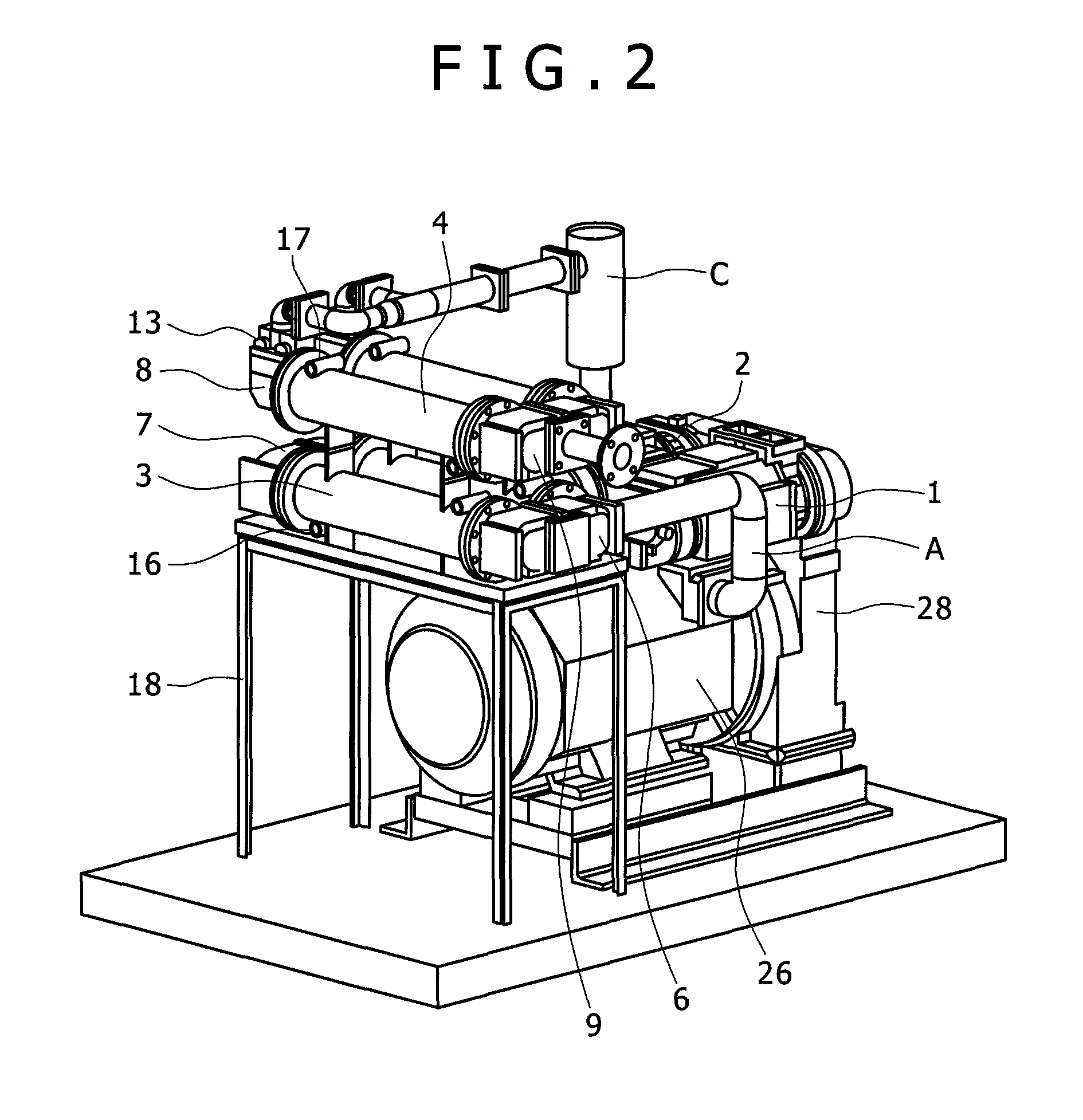

[0048]The first embodiment of the present invention will be described in detail referring to the accompanying drawings. The description will be given below by taking as an example a screw compressor which compresses air by rotation of male and female rotors.

[0049]FIG. 1 is a schematic diagram showing a water-cooled two-stage oil-free screw compressor 30 having a low pressure stage compressor body 1 and a high pressure stage compressor body 2. The low pressure stage compressor body 1 and high pressure stage compressor body 2 each include a pair of rotors, i.e. a male rotor and a female rotor. The compressor according to this embodiment is a screw air compressor which compresses air by rotation of the male and female rotors.

[0050]Pinion gears 21 are fitted to the axial ends of the male rotors of the low pressure stage compressor body 1 and high pressure stage compressor body 2. These pinion gears 21 are engaged with a bull gear 23 fitted to one end of a driving shaft inside a gear cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com