Vapor Compression System With Condensate Intercooling Between Compression Stages

a technology of vapor compression system and compression stage, which is applied in the direction of defrosting, lighting and heating apparatus, and domestic cooling apparatus, to achieve the effects of improving the capacity of the refrigerant vapor compression system, enhancing the heat transfer surface, and improving the heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

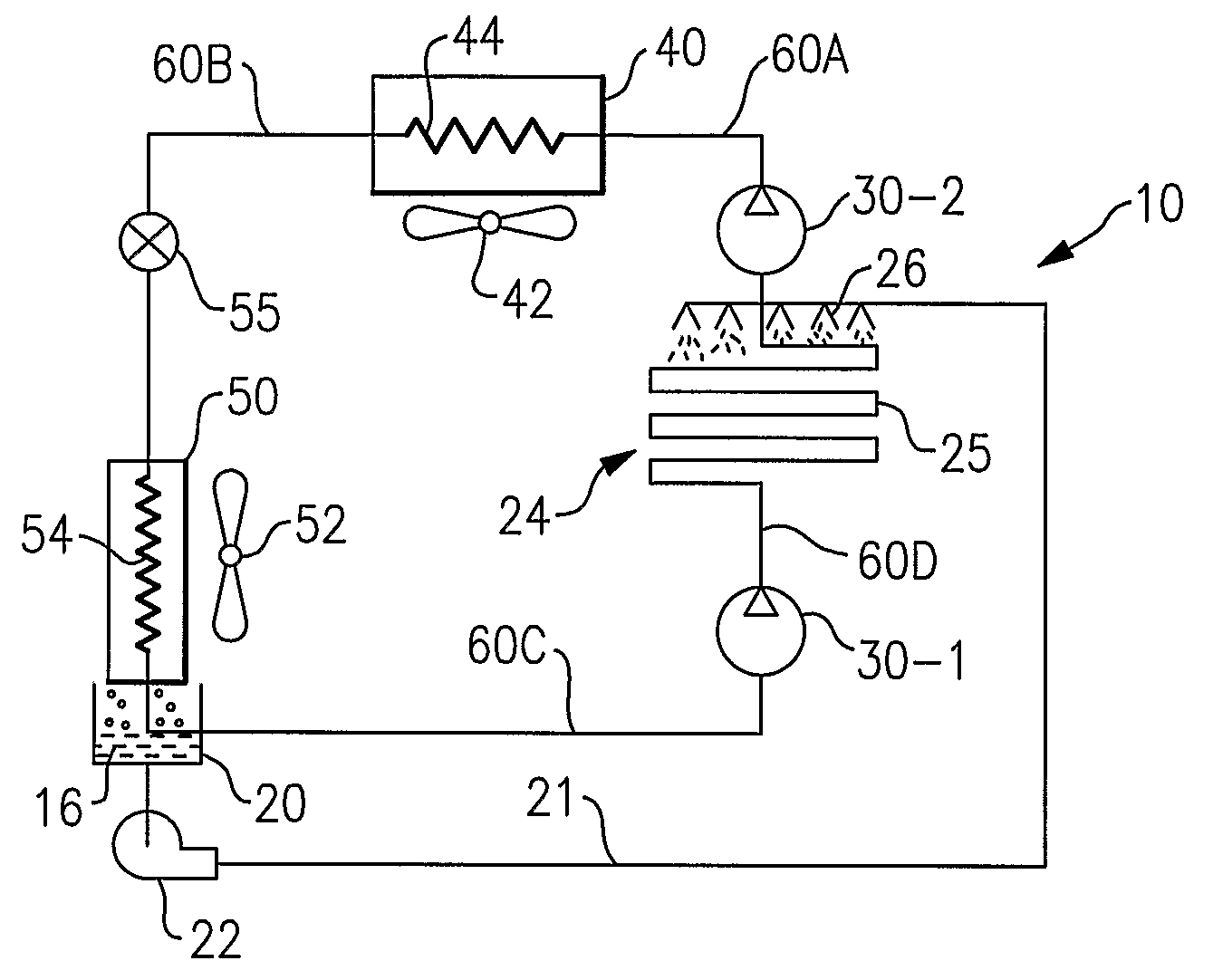

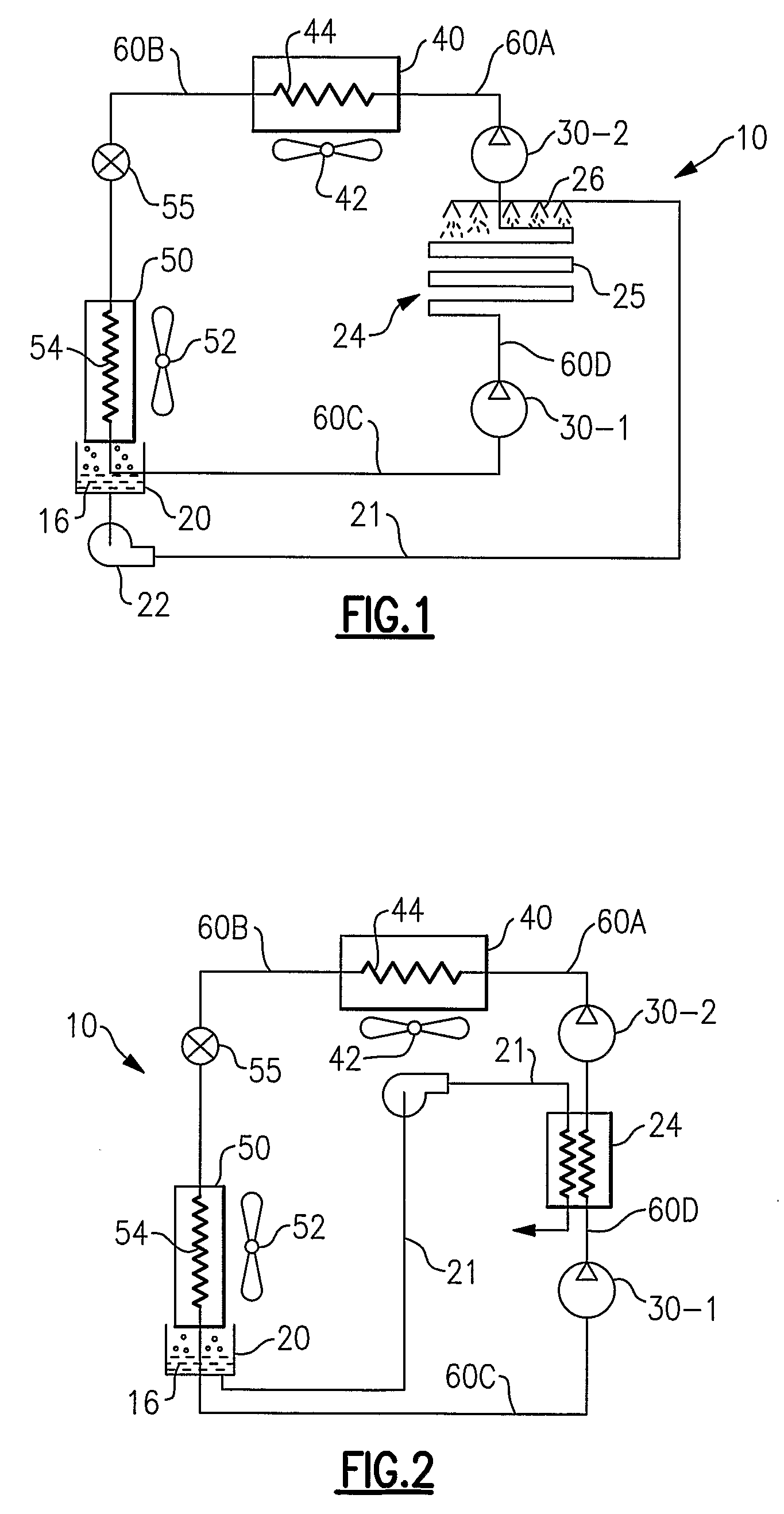

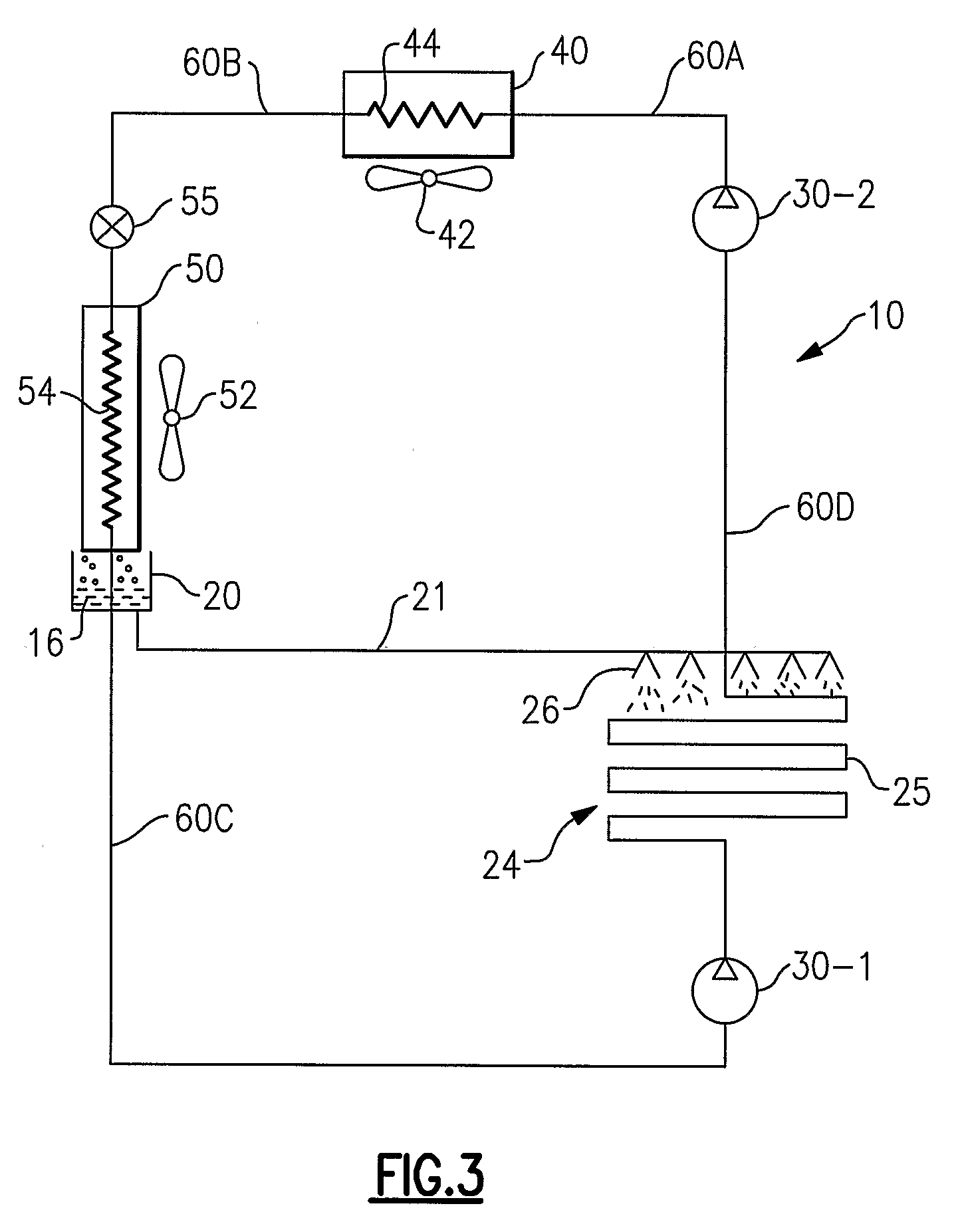

[0019]Referring now to FIGS. 1-4, as in conventional systems, the refrigerant vapor compression system 10 includes a compression device 30, a refrigerant heat rejecting heat exchanger 40, also referred to herein as a gas cooler or a condenser (depending on an application), a refrigerant heat absorbing heat exchanger 50, also referred to herein as an evaporator, an expansion device 55, illustrated as an expansion valve, operatively associated with the evaporator 50, and various refrigerant lines 60A, 60B, 60C and 60D connecting the aforementioned components in a conventional refrigerant circuit. The compression device 30 functions to compress and circulate refrigerant throughout the refrigerant circuit as will be discussed in further detail hereinafter. The compression device 30 may be a scroll compressor, a screw compressor, a reciprocating compressor, a rotary compressor, a centrifugal compressor or any other type of compressor or a plurality of any such compressors. The compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com