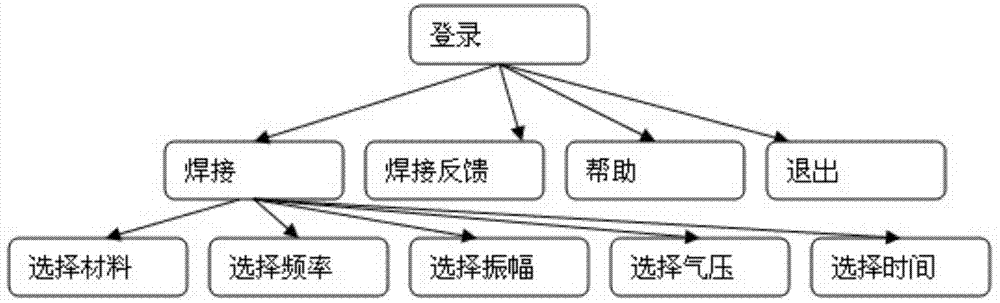

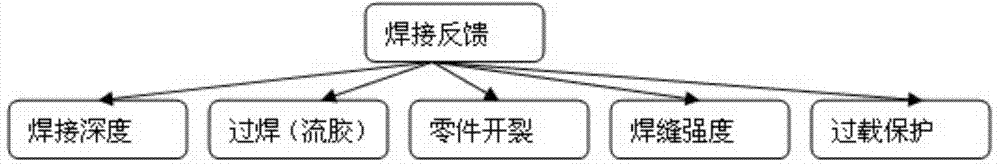

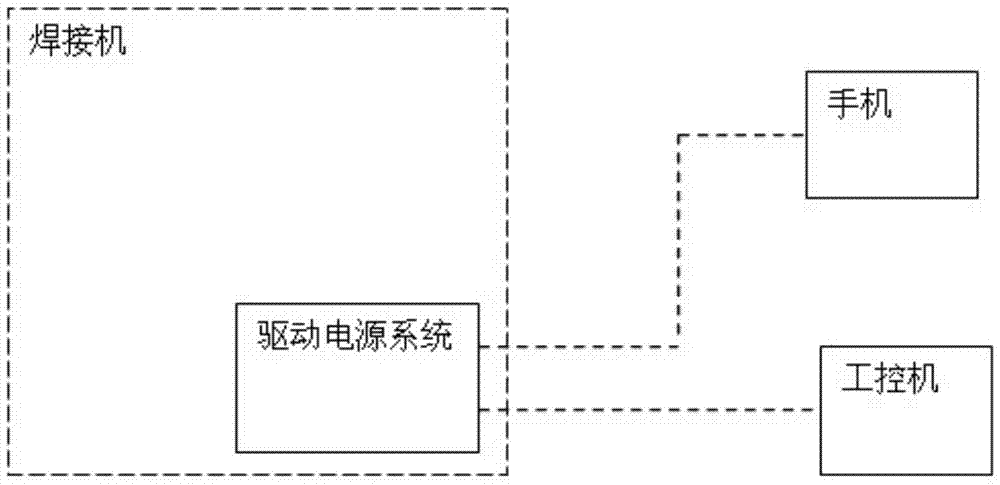

Intelligent adjustment-correction and management method and system for welding parameters of ultrasonic plastic welding machine

A technology of welding parameters and plastic welding, which is applied in the field of intelligent adjustment and management of welding parameters of ultrasonic plastic welding machines, to achieve the effects of reducing the influence of human factors, simplifying the acquisition process, and reducing quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with specific implementation examples.

[0034] The control parameters of the ultrasonic welding machine include machine power, frequency, welding time, amplitude, welding pressure, pressure holding time, delay time, etc. The most important of these are welding time, amplitude, and welding pressure. As for the power, frequency, pressure holding time and delay time of the whole machine, their judgment and setting are very simple, no special means are required, and they can also be included in the scope of adjustment objects if necessary. The specific instructions are as follows:

[0035] 1. Machine power. In actual operation, it is realized by adjusting the power gear or adjusting the power percentage. Inside the welding machine, the amplitude of the ultrasonic horn is actually adjusted. The greater the amplitude, the greater the corresponding power. From the point of view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com