Laser plastic welding method and plastic product

A laser welding and plastic technology, applied in the field of laser welding, can solve the problems of inability to efficiently absorb laser energy, unusable, unstable welding, etc., and achieve the effect of solving plastic surface burns, reducing welding processes, and reducing welding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

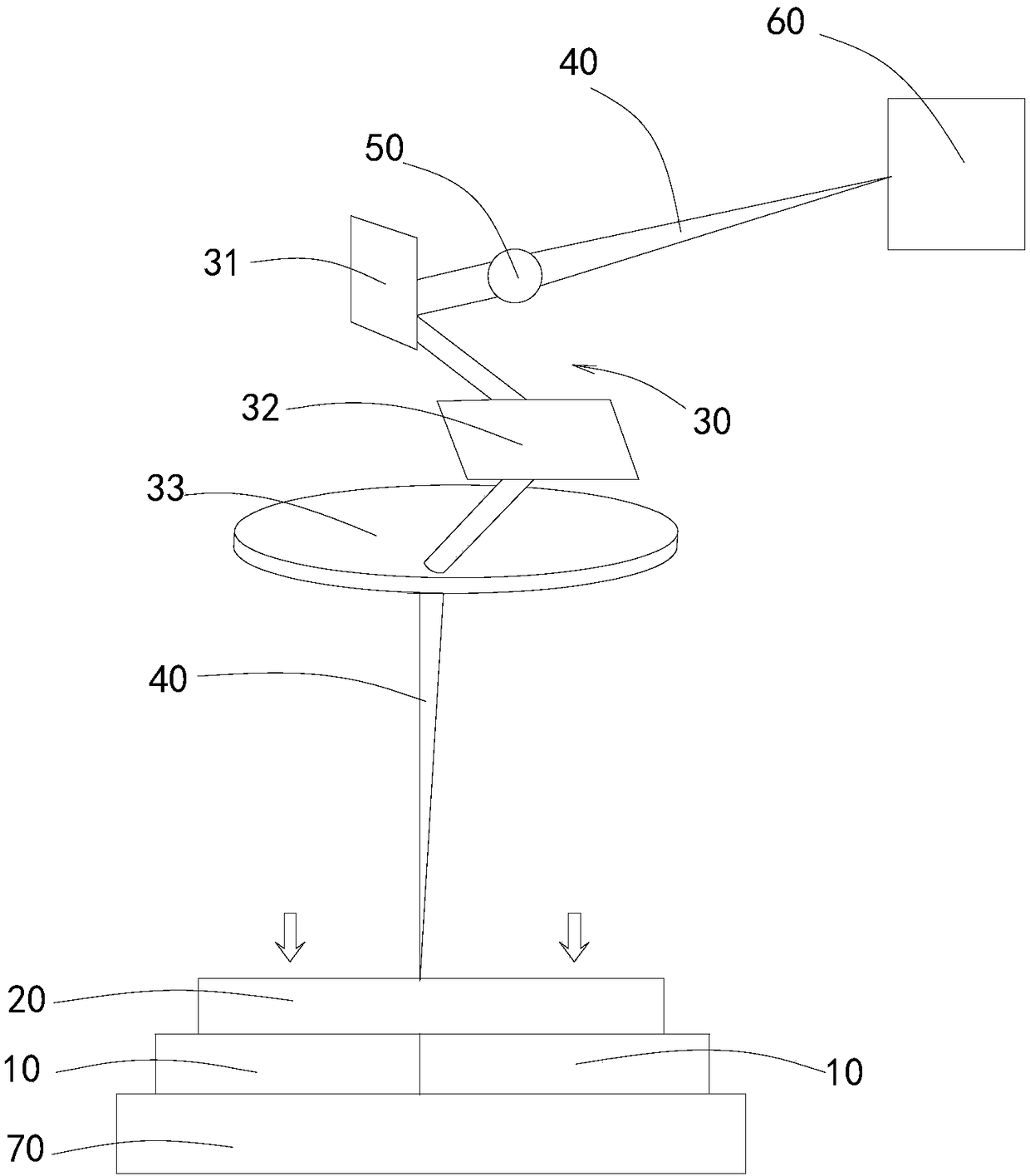

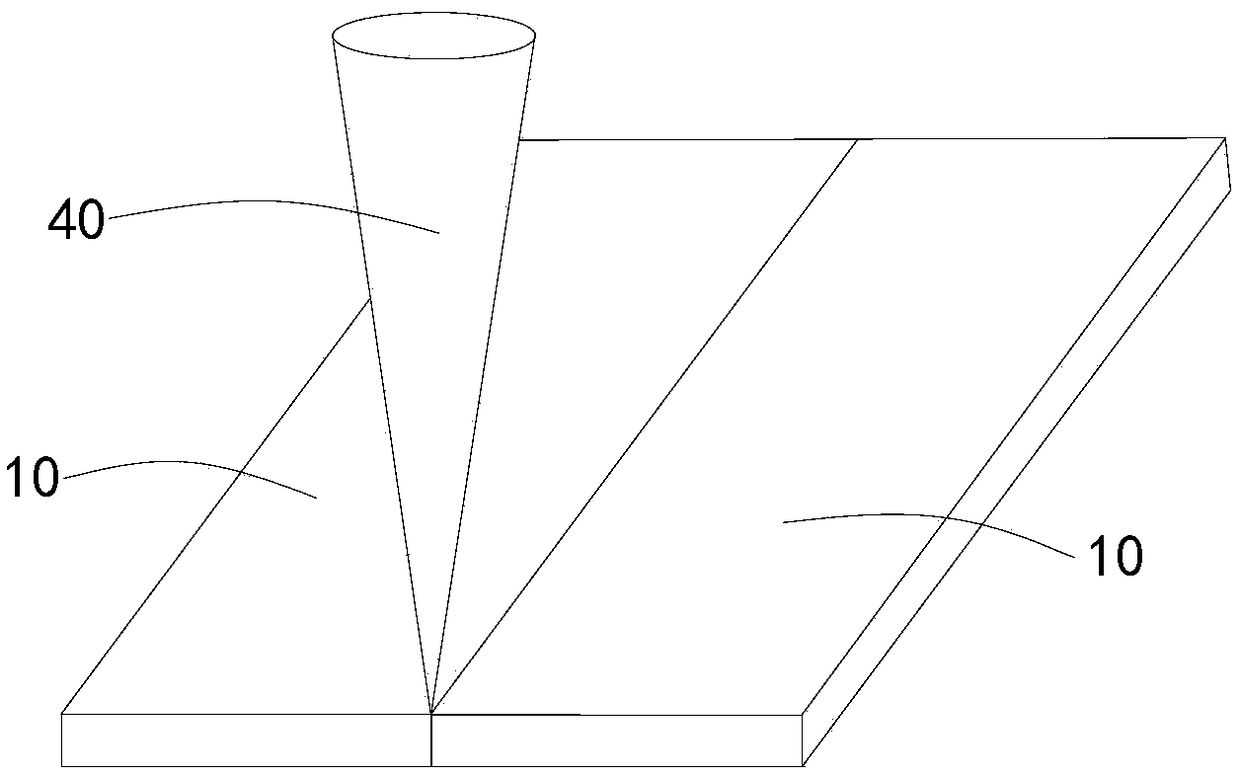

[0045] Please refer to figure 1 , The present invention provides a method for laser welding plastics, which is to butt-weld two pieces of 1mm thick transparent PA plastic 10 together, which includes the following steps: placing two pieces of plastic 10 on a metal workbench 70 and butt together, A sapphire cover 20 is pressed on the top surface of the two pieces of plastic 10 with a thermal conductivity of 45W / (m·K). The pressure of the sapphire cover 20 is guaranteed to be 100N, and a sapphire cover 20 with a wavelength of 1940nm is set above the sapphire cover 20 Mid-infrared thulium-doped fiber laser 60 and galvanometer 30. The diameter of the fiber laser 60 is 400um, the power is about 20W, and the maximum power is 30W. The galvanometer 30 is set near the fiber laser 60 to ensure that the fiber laser 60 emits The laser beam 40 can be transmitted to the galvanometer 30; turn on the fiber laser 60, the fiber laser 60 emits a laser beam 40, the laser beam 40 is transmitted to th...

Embodiment 2

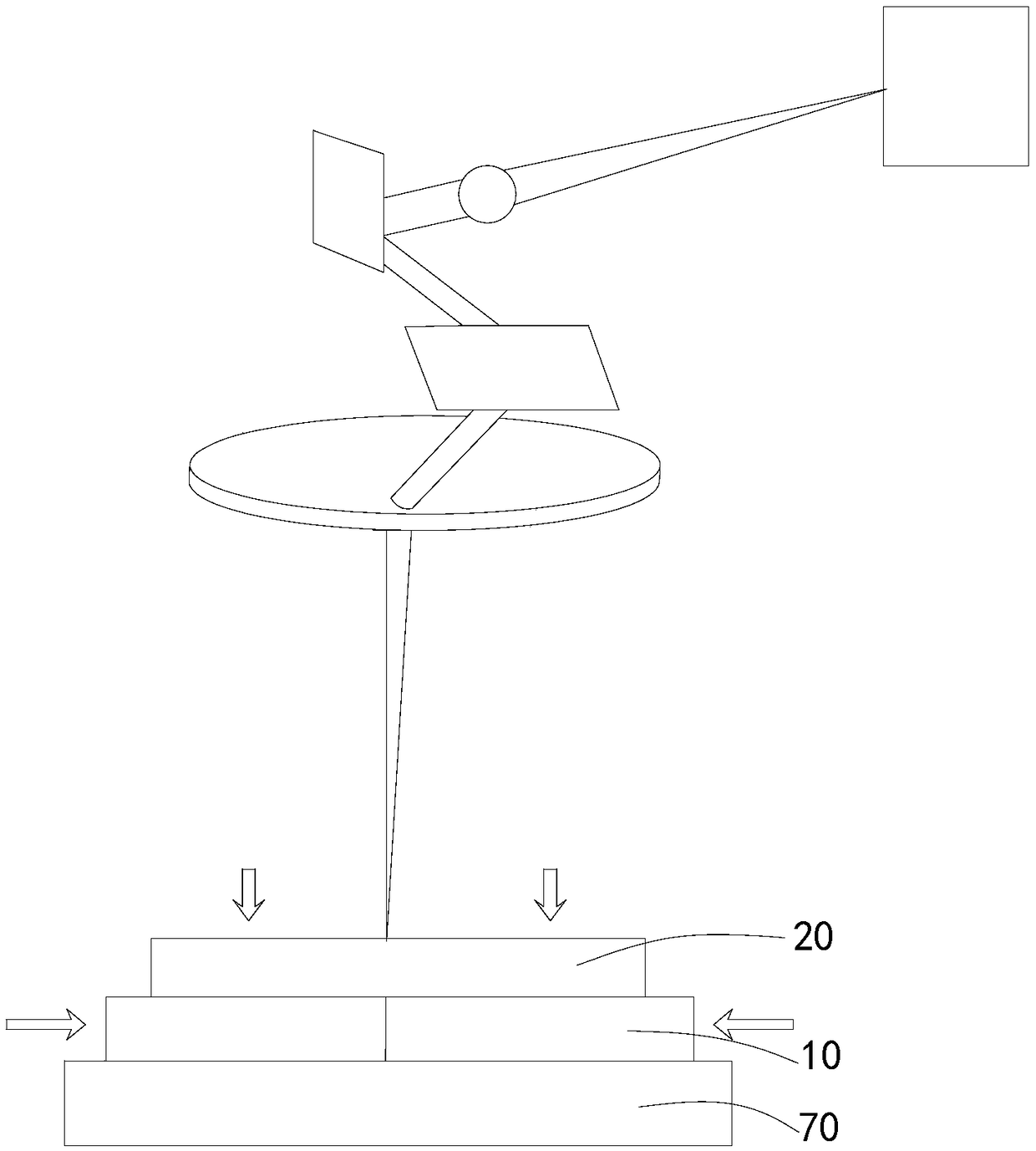

[0050] Please refer to image 3 The difference from the first embodiment is that before the fiber laser 60 is turned on, a pressure of 40N is applied to the opposite sides of the two pieces of plastic 10 far away from the butting gap. After the fiber laser 60 is turned on, the two pieces of plastic 10 are pressed on the left and right sides. A weld is formed under the action to ensure that the butt joint position is fit. If the butt joint of the two pieces of plastic 10 is curved, the laser beam 40 scans along the curved butt joint.

Embodiment 3

[0052] The difference between this embodiment and the first embodiment is that the material of the two pieces of plastic 10 is PET material. After monitoring, the absorption rate of the 1940 nm mid-infrared thulium-doped laser is 85%-90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com