Electromagnetic induction welding of plastic pipe distribution systems

A technology of induction welding and electromagnetic induction, which is applied in the direction of induction heating, pipeline connection arrangement, induction heating device, etc., and can solve problems such as weak welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Induction Weldable Fittings

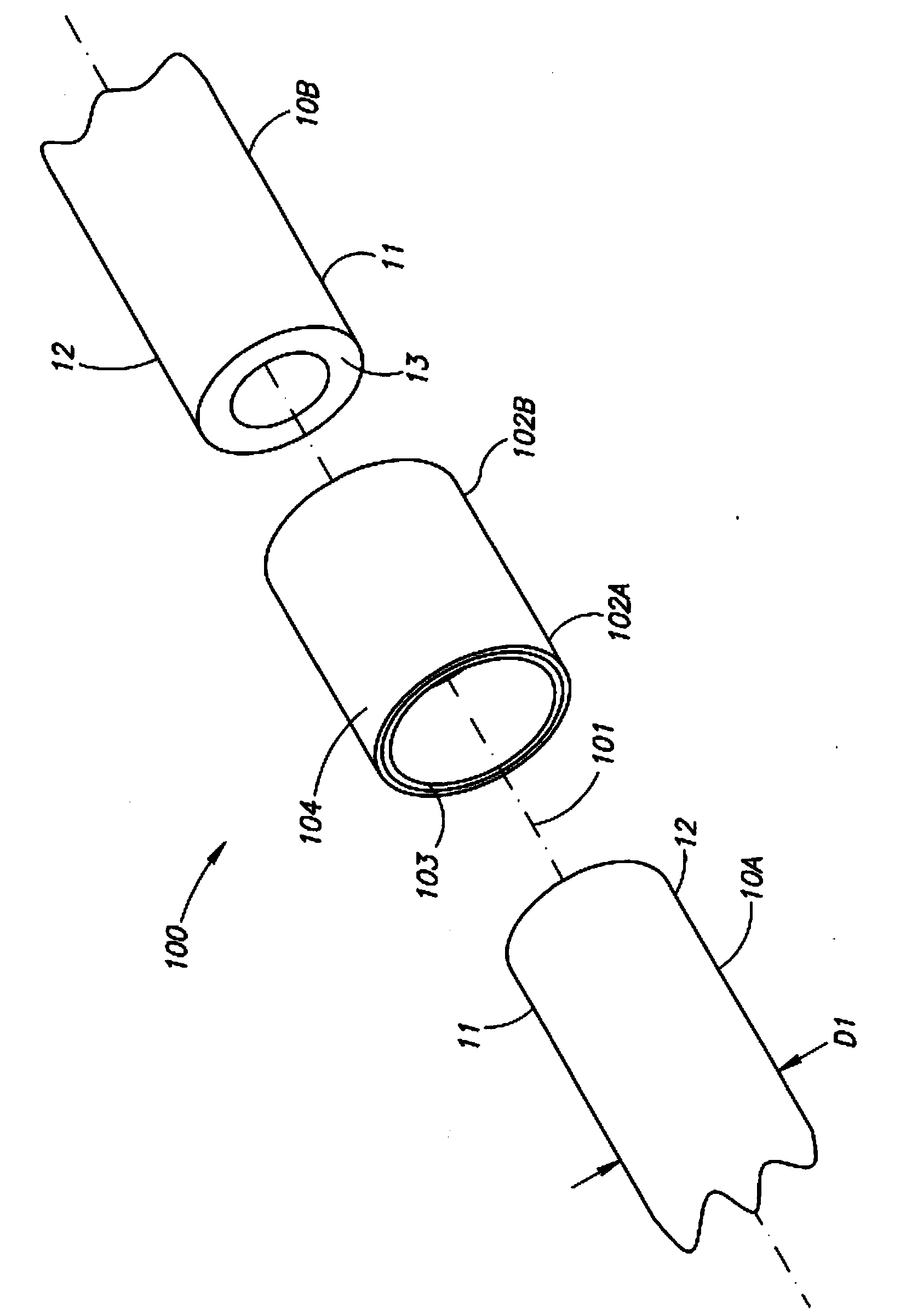

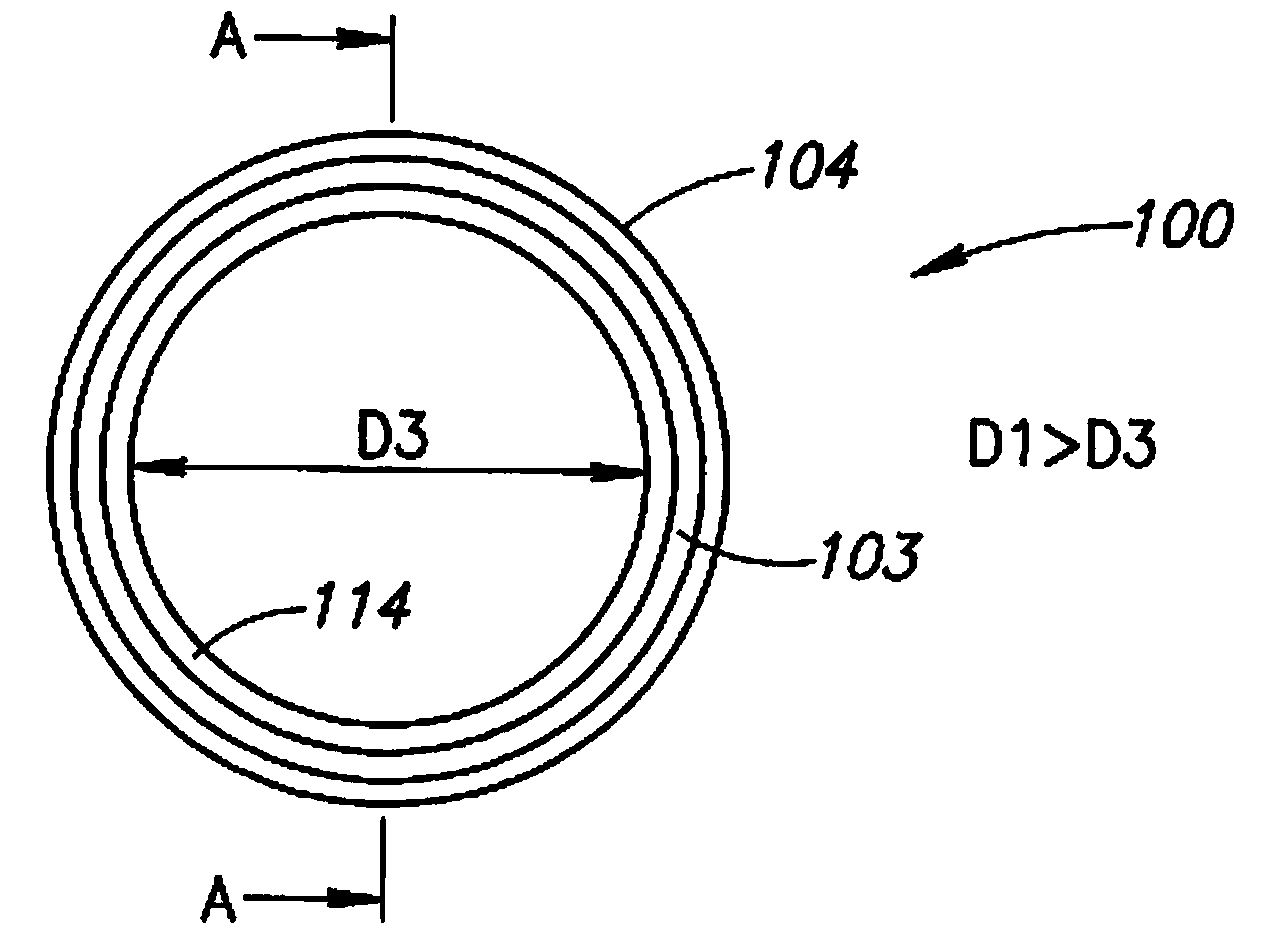

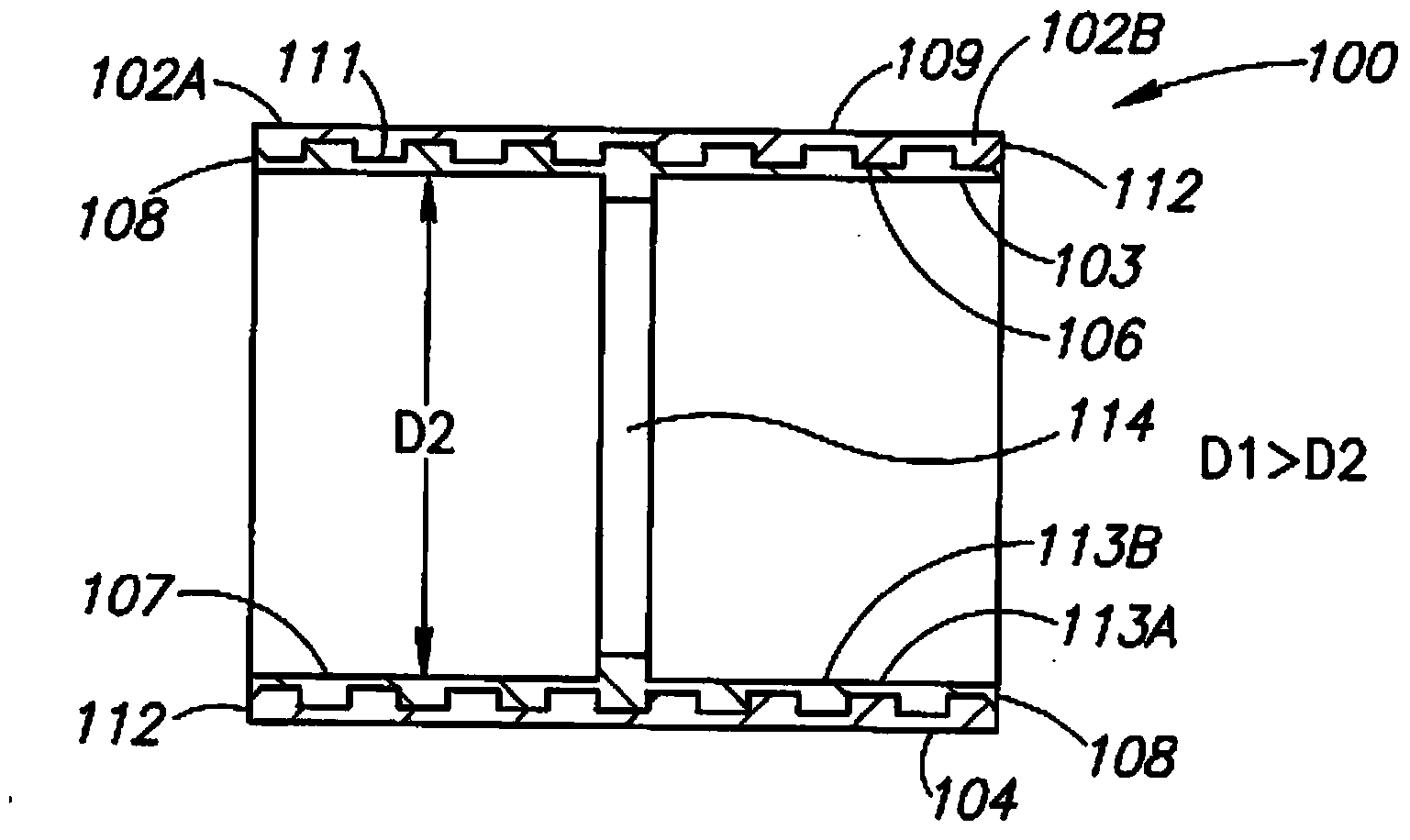

[0037] Figure 1-Figure 4An induction weldable pipe fitting 100 is shown for electromagnetic induction welding to a pair of plastic pipes 10A and 10B. Plastic pipes can be made entirely of a single plastic or have multiple layers. Multilayer compositions are used to provide a better combination of mechanical and chemical properties such as weight, stiffness, strength, chemical resistance, operating pressure, operating temperature, etc. The plastic tube 10 is usually of the same material. The outer diameter D1 of the plastic tube 10 is typically in the range of 10 mm to 30 mm. The plastic tube 10 has a tube end 11 . The pipe end 11 has a circumferential outer pipe end surface 12 and an annular pipe end surface 13 .

[0038] The induction weldable pipe joint 100 has a longitudinal pipe joint shaft 101 and includes two opposite induction weldable pipe sockets 102A and 102B, each for force-sliding insertion of the plastic pipe end 11 the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com