Laser plastic micro-welding method based on LCD space light modulator and device

A technology of spatial light modulator and welding method, applied in optics, instruments, nonlinear optics, etc., can solve the problems of inability to weld micro-fine parts, irregular laser beam melting, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

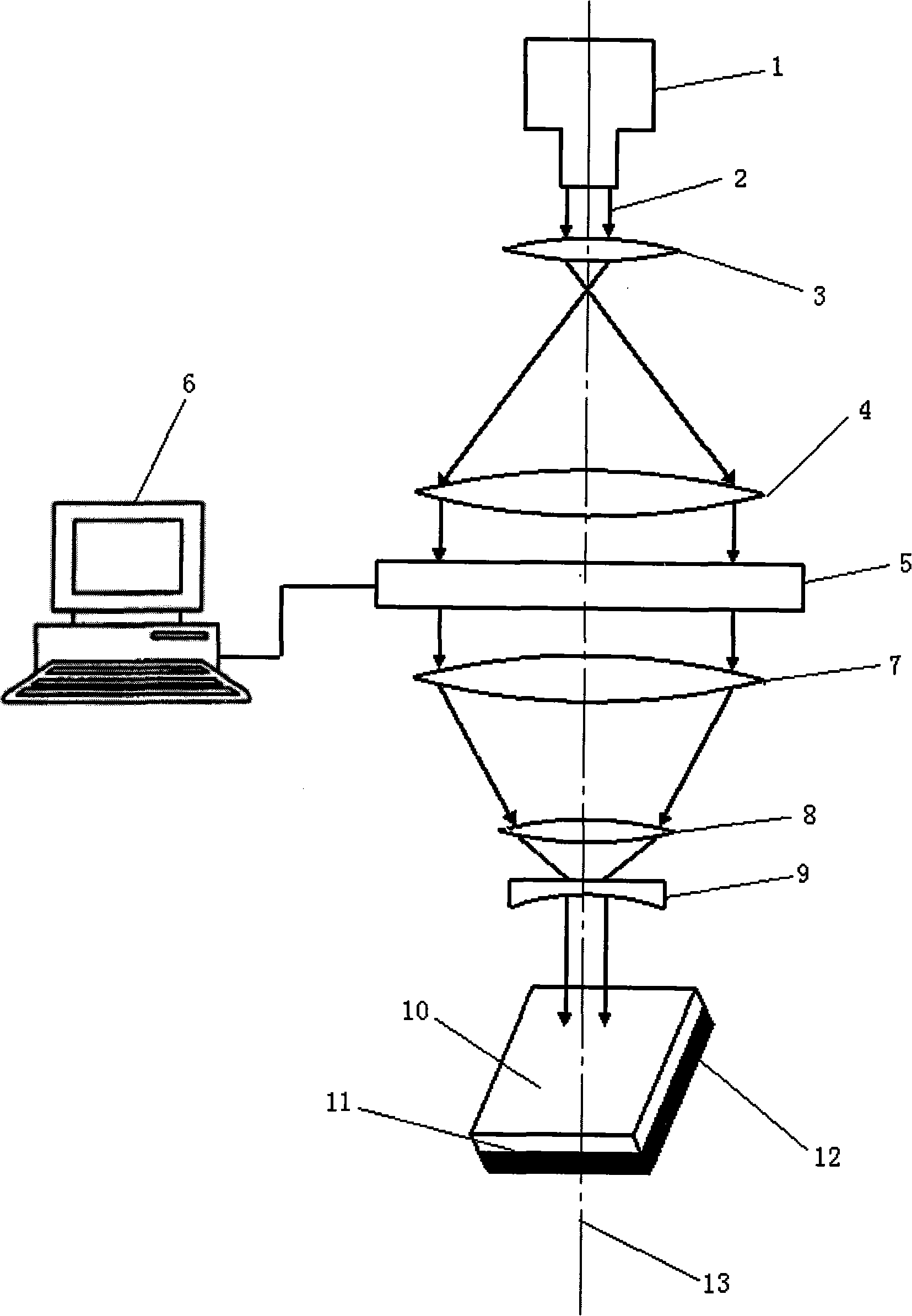

[0020] The laser plastic micro-welding device based on the liquid crystal spatial light modulator proposed by the present invention is as figure 1 shown. It consists of a laser 1, an astigmatism system, a liquid crystal spatial light modulator 5, a computer 6, and a focusing system; the astigmatism system consists of two convex lenses with different focal lengths, the convex lens 3 with a small focal length is placed above the laser 1, and the convex lens 4 with a large focal length Place it far below the laser 1; just below the astigmatism system is a liquid crystal spatial light modulator 5, and the liquid crystal spatial light modulator 5 is connected to the computer 6 through a data line; just below the liquid crystal spatial light modulator 5 is a focusing system, which consists of two Convex lenses with different focal lengths and a concave lens. The three lenses are convex lens 7 with large focal length, convex lens 8 with small focal length and concave lens 9 from top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com