Austenitic stainless steel welding technology

A technology of austenitic stainless steel and welding technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of large argon consumption, rising welding costs, restrictions, etc., and achieve obvious economic benefits and welding The effect of cost reduction and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

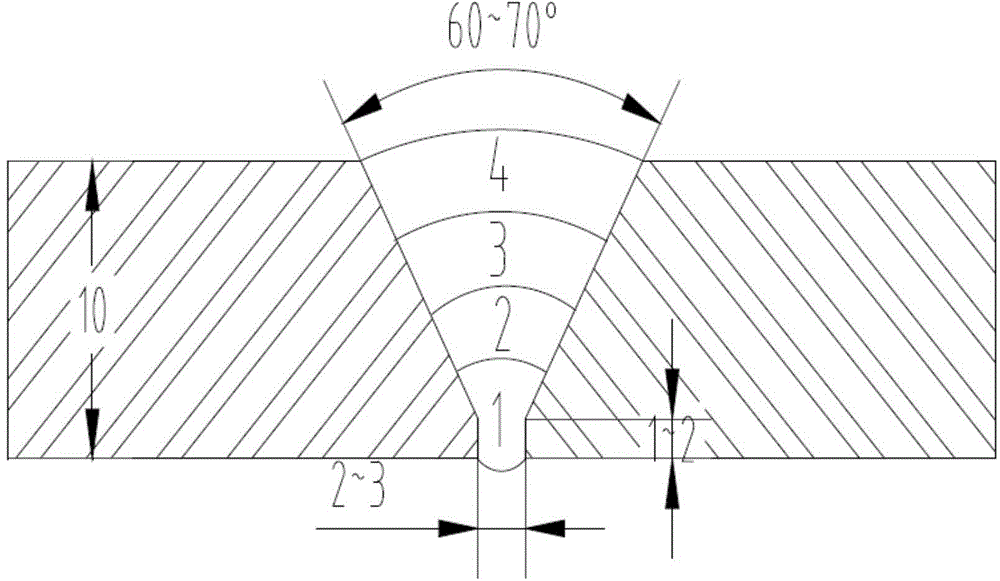

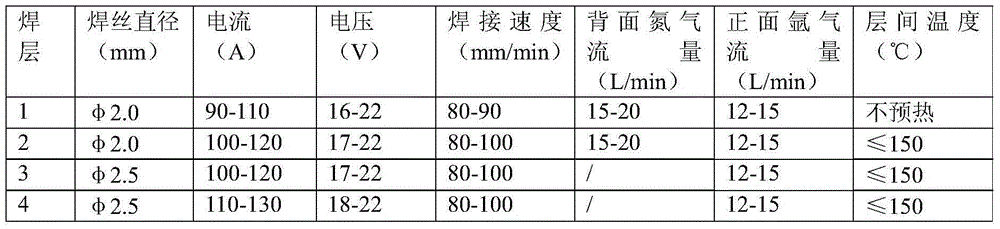

[0018] Refer to attached figure 1

[0019] The stainless steel sheet material is 06Cr19Ni10, the thickness is 10mm, the welding wire type is ER308L, and the V-shaped groove is adopted. The following steps and process parameters are used to make:

[0020] 1) Process a bevel at the stainless steel joint by machining, and use acetone to remove oil and harmful impurities within 20 mm of the surface of the bevel and the base material on both sides of the bevel, and make the welded part and the surrounding area reveal metallic luster. Dry the bevel and surrounding area without residual moisture.

[0021] 2) Selection of weld bevel shape: V-shaped bevel with groove angle of 60°, blunt edge thickness of 2mm, and eliminate burrs.

[0022] 3) The gap between base metal groups is 2mm, and the misalignment of the inner surface of the base metal is less than 2mm.

[0023] 4) The back of the weld adopts airtight measures, only the air inlet and outlet are opened, the back of the weld us...

Embodiment 2

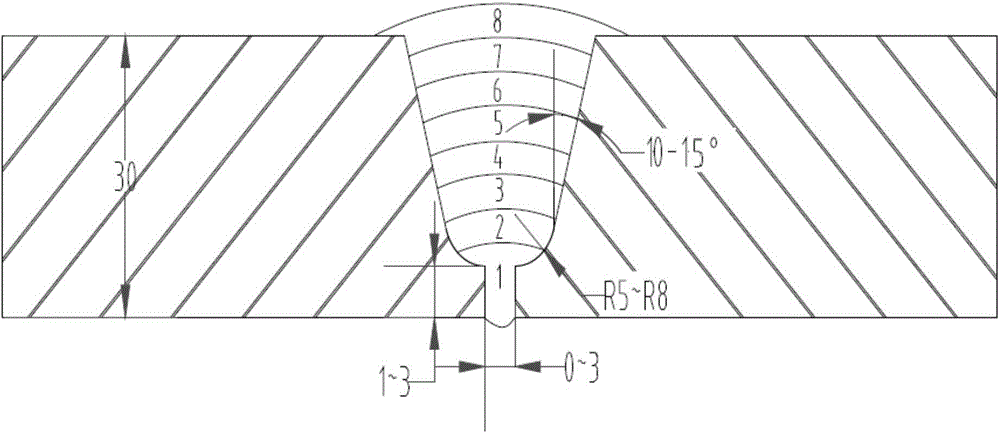

[0035] Refer to attached figure 2

[0036] The stainless steel sheet material is 022Cr17Ni12Mo2, the thickness is 30mm, the welding wire type is ER316L, and the U-shaped groove is adopted. The following steps and process parameters are used to make:

[0037] 1) Process a bevel at the stainless steel joint by machining, and use acetone to remove oil and harmful impurities within 20 mm of the surface of the bevel and the base material on both sides of the bevel, and make the welded part and the surrounding area reveal metallic luster. Dry the bevel and surrounding area without residual moisture.

[0038] 2) Selection of weld groove shape: U-shaped groove with groove angle of 30°, blunt edge thickness of 2mm, and eliminate burrs.

[0039] 3) The gap between base metal groups is 2mm, and the misalignment of the inner surface of the base metal is less than 2mm.

[0040] 4) Sealing measures are adopted on the back of the weld, and only the air inlet and outlet are opened. The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com