Quick-heating electric soldering iron heating head

A technology of heating head and electric soldering iron, applied in the direction of soldering iron, electric heating device, metal processing equipment, etc., can solve the problems of severe oxidation reaction of heating wire, severe oxidation reaction, slow response of hot head, etc., to save raw materials, easy process stability, The effect of consistency control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

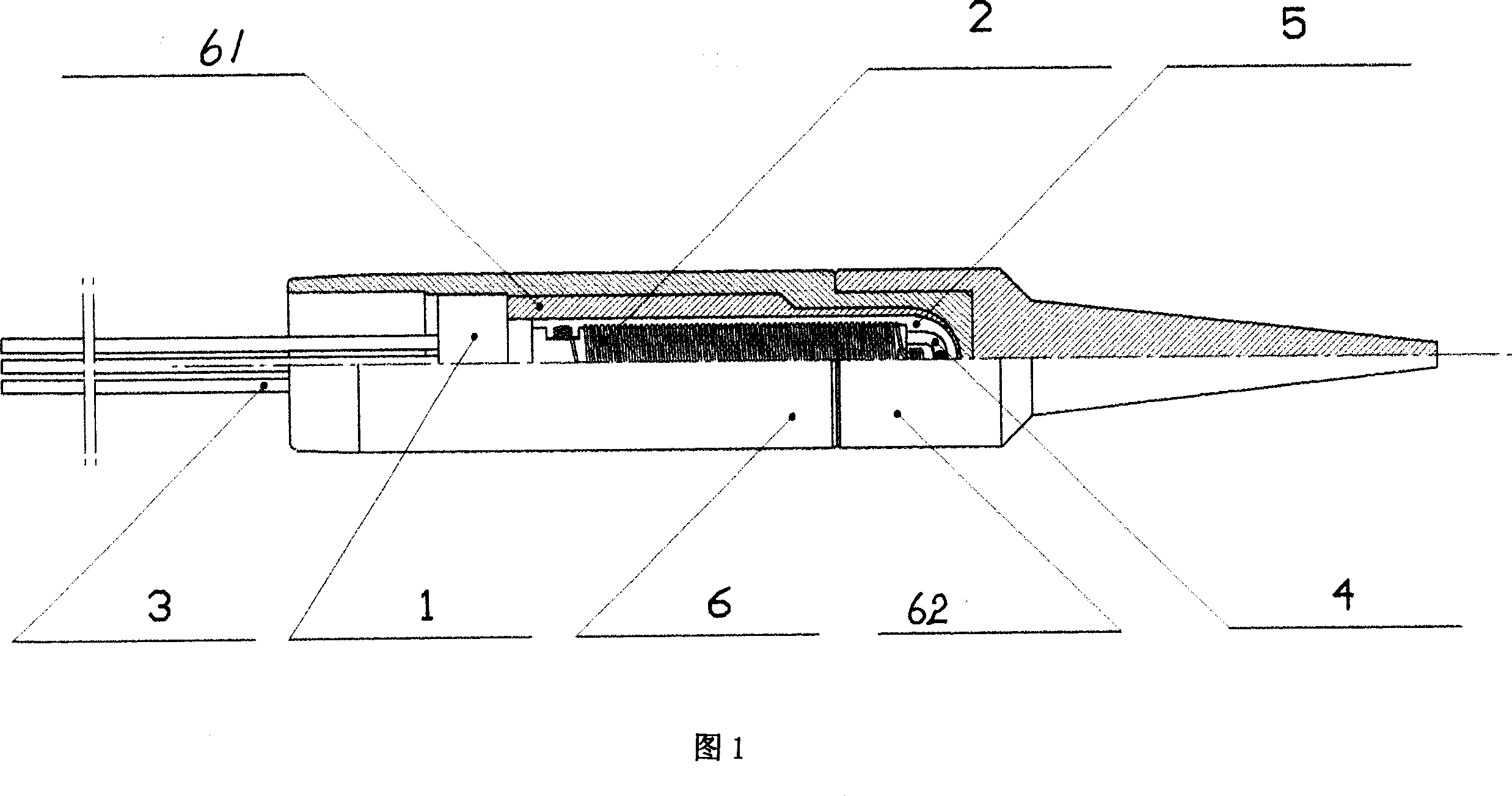

[0018] Insulating base 1 is made of insulating porcelain core base, heating wire 2 is made of electric heating wire with good oxidation resistance, sensor 4 is made of thermocouple temperature sensor, insulating layer 5 is made of high temperature resistant insulating porcelain or insulating glaze, and outer metal heat conductor 6 Stainless steel or copper is used, the inner metal heat conductor 61 is made of a metal with a lower melting point than the outer metal heat conductor 6, such as copper or aluminum, and the soldering iron tip 62 is usually made of copper.

[0019] Structurally, the heating head of the fast-heating electric soldering iron of the present invention is provided with a heating wire 2 on the insulating base 1 to form a heating core, an insulating layer 5 is arranged outside the heating core, and an outer metal heat conductor is arranged outside the insulating layer 5 6. The end of the outer metal heat conductor 6 is a soldering iron tip 62, in which the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com