Electronic component welding method

A technology of electronic components and welding methods, which is applied in the direction of assembling printed circuits with electrical components, welding equipment, manufacturing tools, etc., and can solve problems such as virtual soldering, easy cold soldering of products, and difficulty in heating solder paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

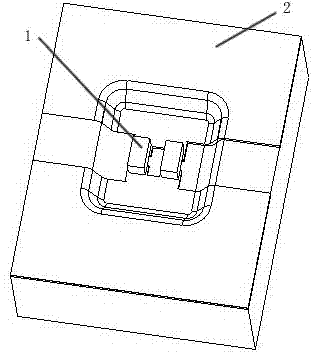

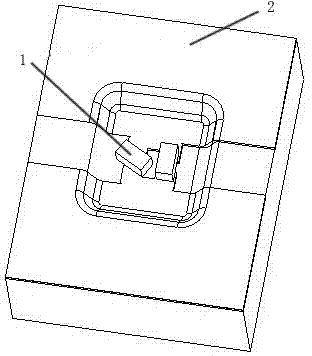

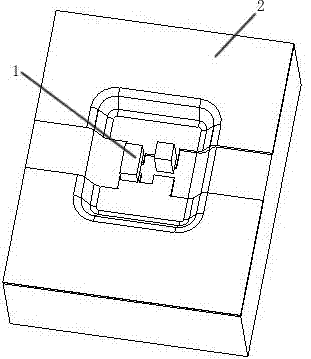

[0030] A welding method for electronic components 1, comprising the following steps:

[0031] First, do a pit structure treatment at the position of the carrier 2 where the component 1 needs to be welded to obtain a pit that matches the structure of the component 1;

[0032] Then, place the component 1 in the pit, and then apply the solder paste 3 on the top of the component 1 and between the component 1 and the side wall of the pit;

[0033] The solder paste 3 is heated, and the solder paste 3 absorbs the heat and solidifies to complete the soldering.

[0034] The volume of the pit is larger than the volume of the component 1, which heats the solder paste 3 through a reflow soldering furnace, and the carrier 2 includes a PCB and a plastic body, and can also be a carrier 2 of other materials. List them all. The surface of the carrier 2 is a profiled surface, that is, an uneven surface.

[0035] It heats the solder paste 3 through a reflow soldering furnace, the pre-solderin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com