Plastic welding machine for oil-gas separator, and plastic welding method

A technology of oil and gas separators and plastics, which is applied in applications, household appliances, household components, etc. It can solve problems affecting quality, affecting aesthetics, and weak welding, etc., and achieves the effect of uniform heating and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

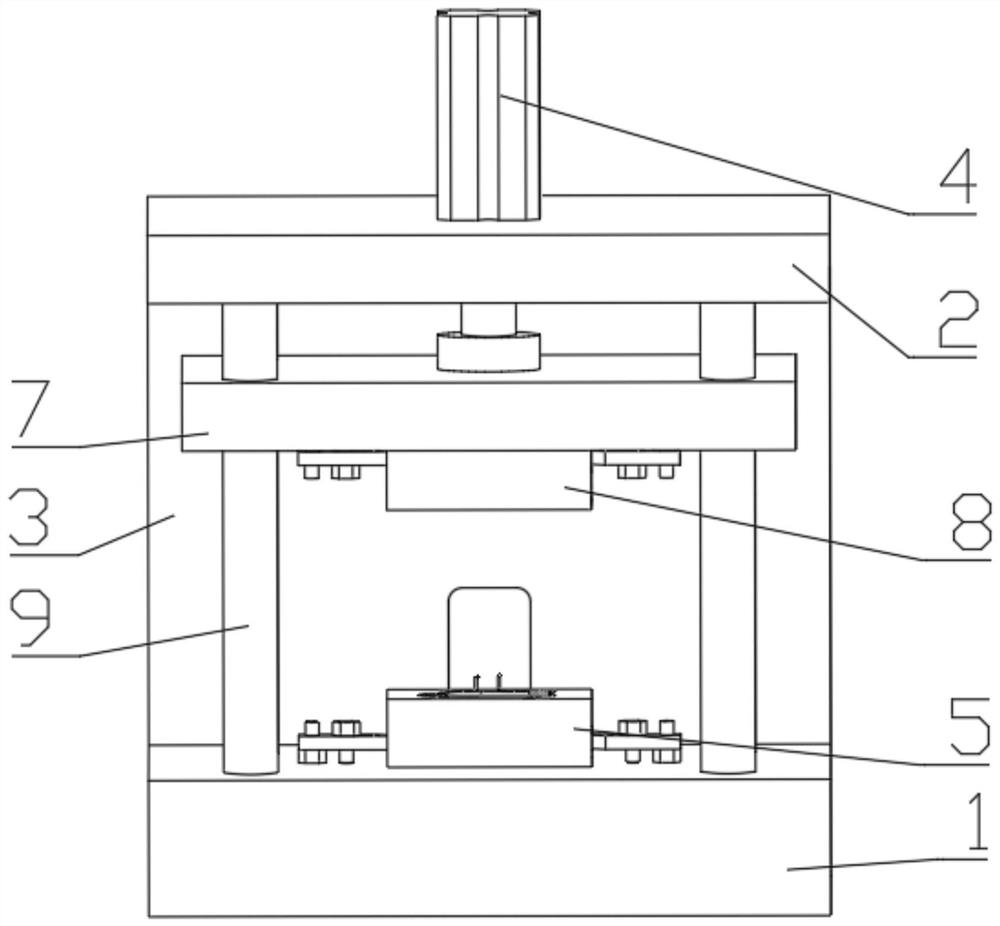

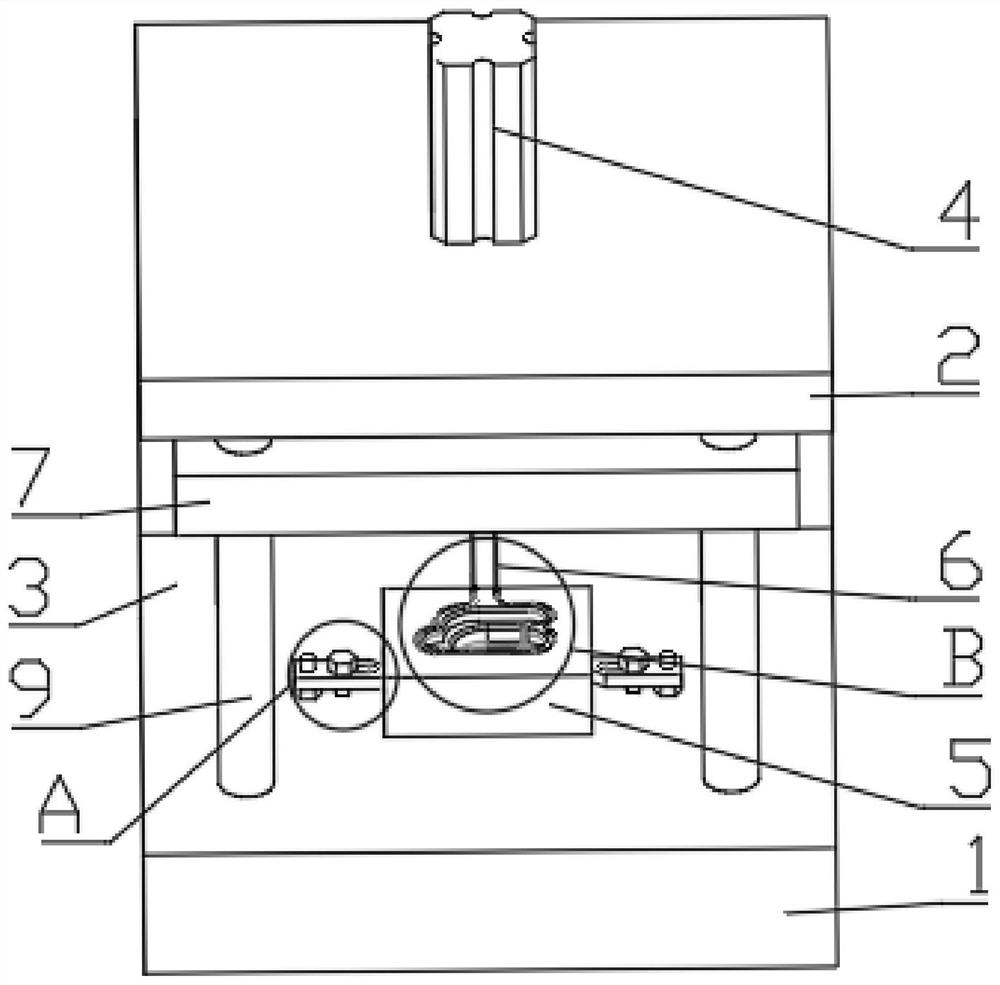

[0031] A kind of plastic welding machine used for oil-gas separator of the present invention is described in detail below in conjunction with accompanying drawing.

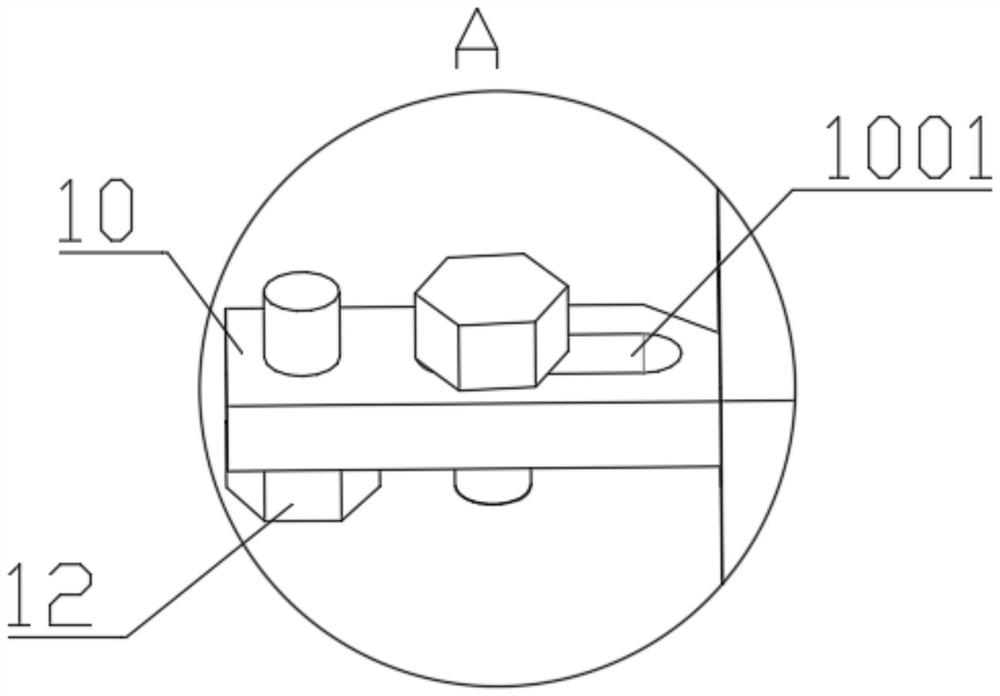

[0032] Such as Figures 1 to 7 As shown, a plastic welding machine for an oil-gas separator, which includes a base 1, a top plate 2 is integrally formed on the base 1, a working chamber 3 is provided between the base 1 and the top plate 2, and a driving device is provided on the top plate 2 4. The upper surface of the base 1 is provided with a lower die 5, the lower die 5 is provided with a lower die cavity 501 and a first groove 502, the first groove 502 is located around the lower die cavity 501 and extends along the outer edge of the lower die cavity 501, the first Both ends of the groove 502 are located on the same side of the lower mold 5 . A copper tube 6 is arranged in the first groove 502, and the copper tube 6 is externally connected with a variable high-frequency current. The working cavity 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com