Control method and device for arc energy and computer readable medium

An arc energy and control method technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of uncontrollable welding power output, poor heat input control effect, etc., and achieve good quality and small heat input. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

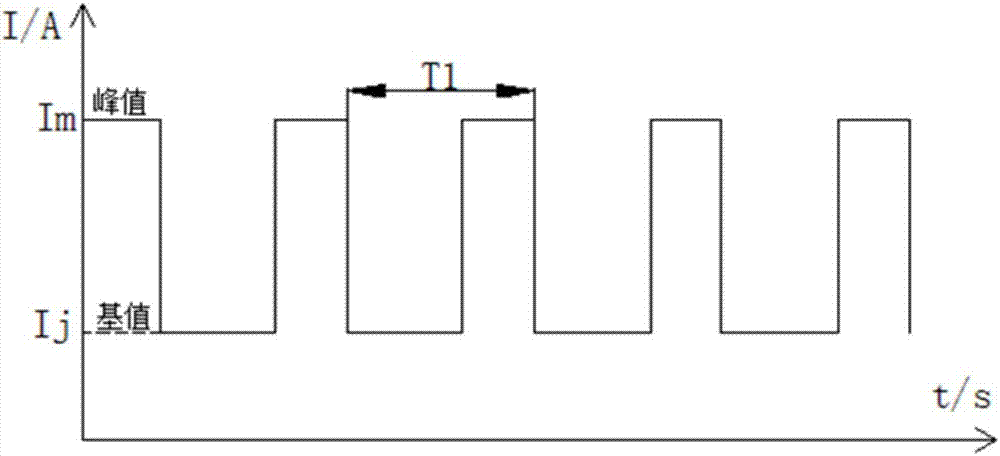

[0037] figure 1 A schematic diagram of the output waveform of an existing pulse welding power supply is given. In the existing pulse welding, the welding power supply periodically outputs pulse current I (unit is ampere A) with time t (unit is second s), the period of pulse current is T1, the peak value of pulse current is Im, and the pulse current The base value of is Ij.

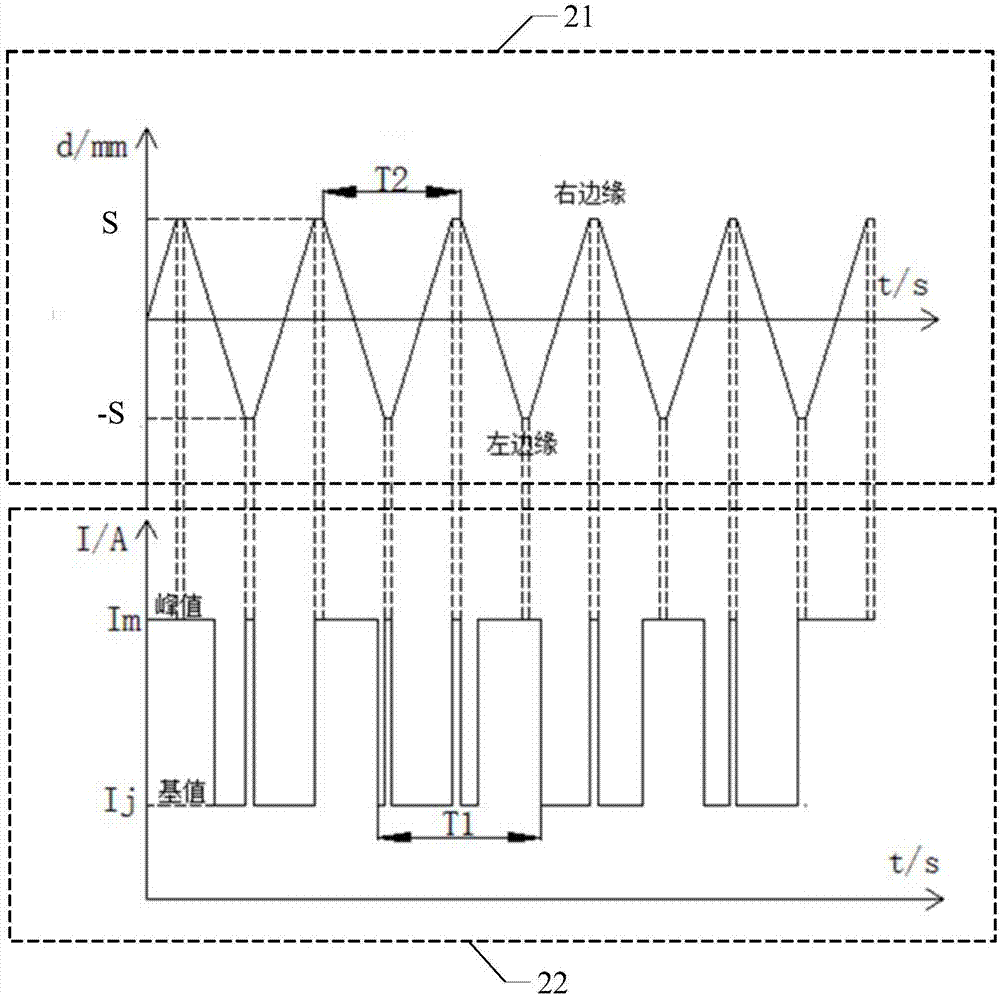

[0038] For oscillating arc welding, the existing control method based on the arc position is applied to control the output current of the pulse welding during the welding process. When the arc reaches the edge of the weld, the output of the welding power supply is forced to the base value of the pulse current or pulse peak current. The schematic diagram of the power output waveform of pulse welding based on arc position control is as follows: figure 2 shown.

[0039] see figure 2 , the upper figure 21 is a schematic diagram of the periodic swing of the arc position with time t (unit is second s), wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com