Stirrup centering and welding mechanism, system and method

A welding mechanism and stirrup technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of high labor intensity, low efficiency, poor welding quality, etc., and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

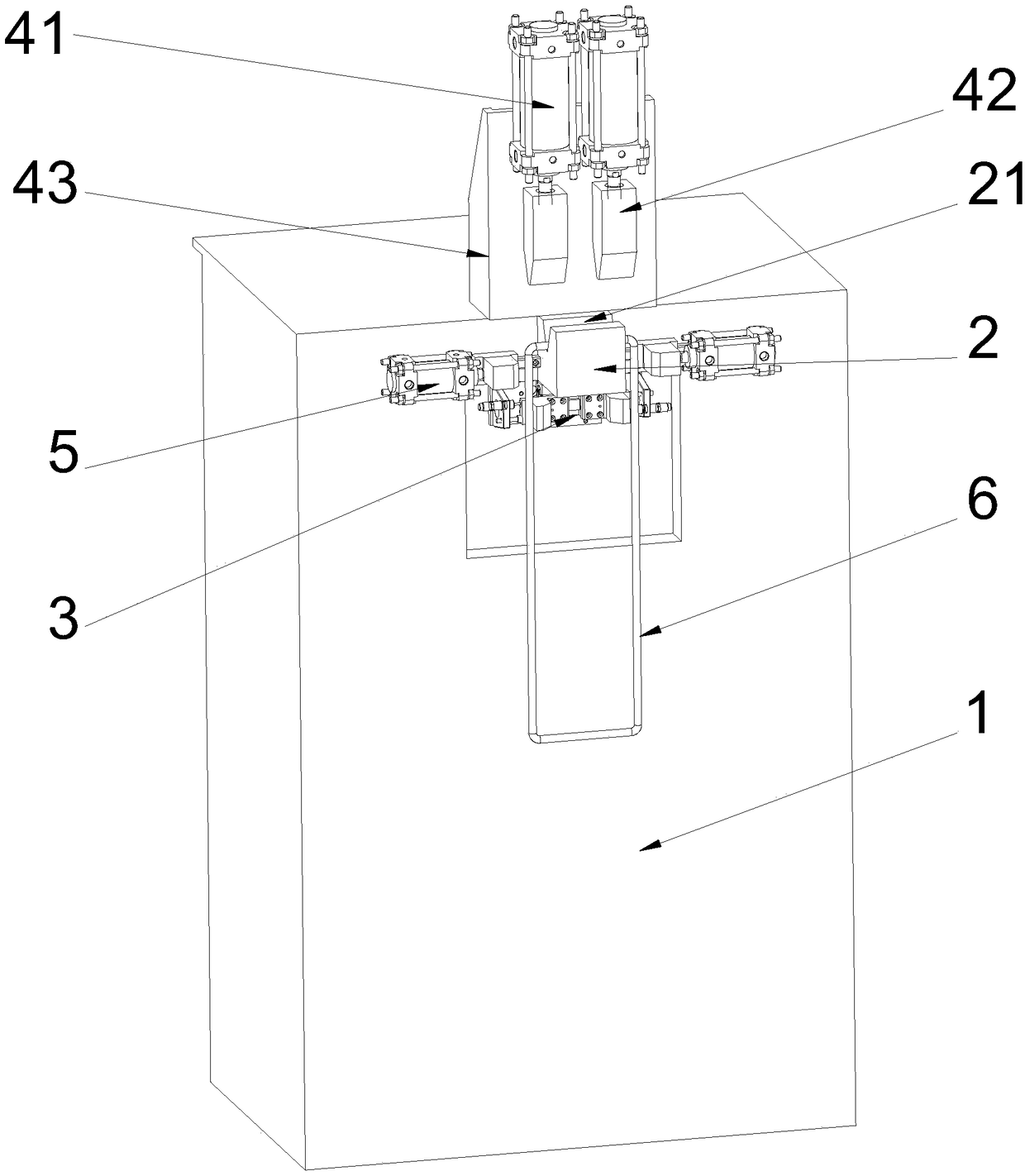

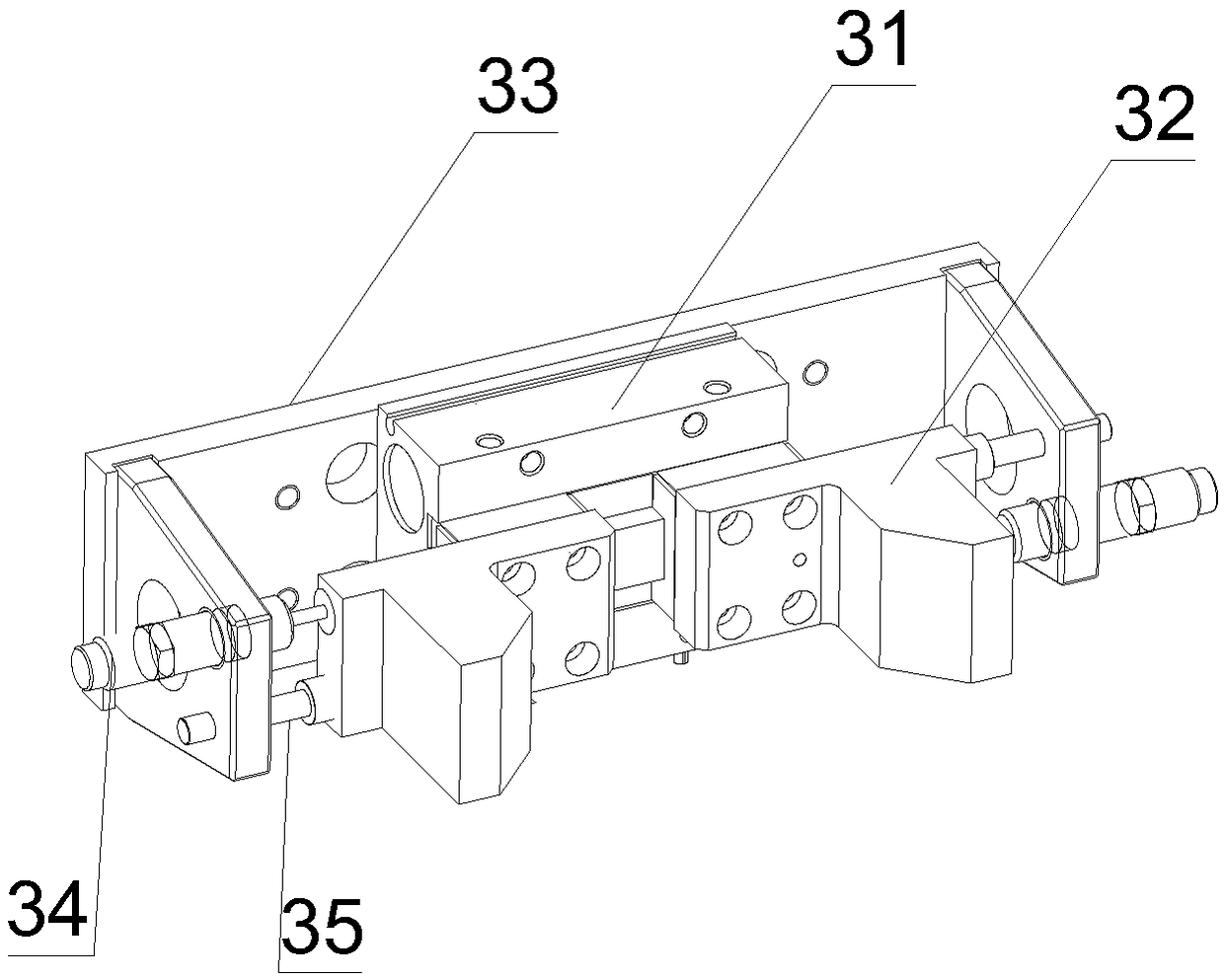

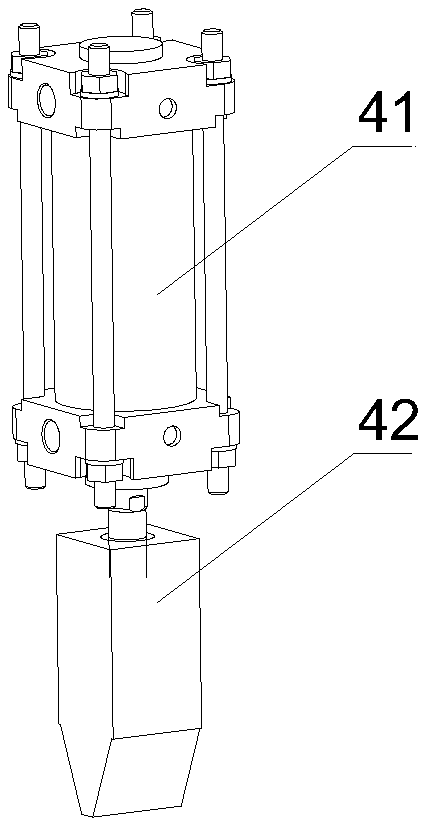

[0036] This embodiment provides a stirrup centering welding mechanism, such as figure 1 As shown, it includes a support body 1 and an upper welding electrode 42 arranged on the support body 1, a lower welding electrode 2, a stretching assembly 3, a pressing driver and a centering assembly 5; the upper surface of the lower welding electrode 2 has a V-shaped Groove 21, V-shaped groove 21 runs through the lower welding electrode 2 in the length direction, V-shaped groove 21 is used to place the two joints of the stirrups 6 to be welded; the expansion component 3 is used to expand the stirrups to be welded outward 6 and make the two joints of the stirrup 6 to be welded in a non-overlapping state; the pressing material driver is used to drive the upper welding electrode 42 to press the two joints in a non-overlapping state located in the V-shaped groove 21 , and make the axes of the two joints collinear; during the welding of the two joints of the stirrup 6 by the lower welding ele...

Embodiment 2

[0050] This embodiment provides a stirrup centering welding system, including a six-axis robot and the stirrup centering welding mechanism in Embodiment 1. A clamping assembly 7 is connected to the handle of the six-axis robot, and the clamping assembly 7 is used to grasp Get the stirrup 6 to be welded and place the side arm of the stirrup 6 to be welded in the V-shaped groove 21 with the joint.

[0051] Such as Figure 5 As shown, there are multiple sets of clamping assemblies 7, and each set of clamping assemblies 7 includes a jaw cylinder 71 and a jaw 72, and the jaw cylinder 71 is fixedly arranged on a flat plate 73 for connecting with a handle of a six-axis robot , the jaw cylinder 71 is used to drive the jaw 72 to clamp or loosen a side arm of the stirrup 6 to be welded, and each vertical side arm corresponding to the stirrup 6 to be welded on the flat plate 73 is provided with at least A clamping assembly 7.

[0052] There are 4 sets of clamping assemblies 7, and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com