Longitudinal joint automatic welding machine

An automatic welding machine and longitudinal seam technology, applied in welding equipment, welding equipment, arc welding equipment, etc., to prevent the welding position from changing, make good contact, and solve the effect of poor consistency of weld quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

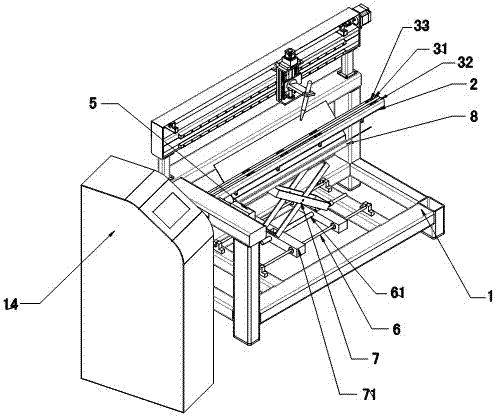

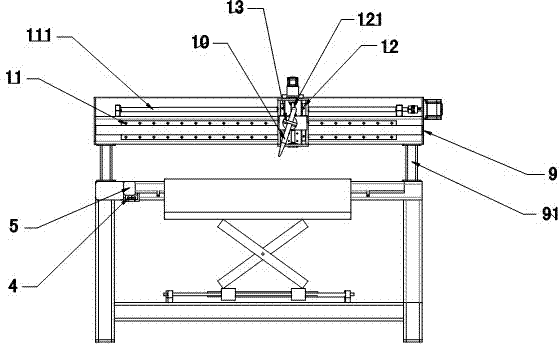

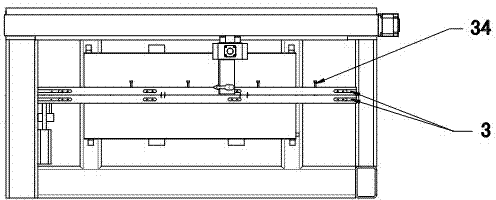

[0025] Figure 1 to Figure 4 A preferred embodiment of the automatic longitudinal seam welding machine of the present invention is shown, the welding machine includes a frame 1, an adsorption base 2, a vacuum adsorption tube 3, a vacuum fixed adsorption tube 31, a vacuum mobile adsorption tube 32, an adsorption port 33, Adjusting pin 34, horizontal guide rail 4, cylinder 5, lifting guide rail 6, X-shaped support frame 7, lifting adjustment screw 61, X-shaped support base 71, V-shaped bracket 8, beam 9, beam column 91, welding torch 10, X Axis guide rail 11, X-axis ball screw 111, Z-axis guide rail 12, Z-axis ball screw 121, rotating mechanism 13, and control cabinet 14.

[0026] Such as figure 1 , figure 2 and image 3 As shown, the upper end of the frame 1 is provided with an adsorption base 2, and the upper surface of the adsorption base is provided with two vacuum adsorption tubes 3 for absorbing workpieces along its length direction. The two vacuum adsorption tubes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com