Environment-friendly and low-temperature residue-free solder paste and preparing method thereof

A technology without residue and solder paste, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of poor weldability of Sn-Bi alloy, etc., achieve less residue after soldering, promote wetting, and transparent residue after soldering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

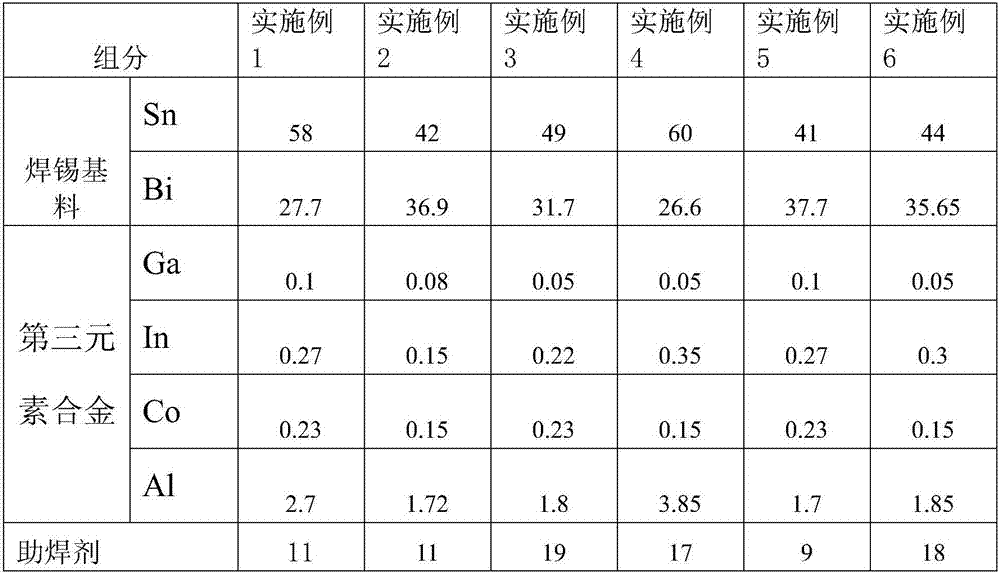

Embodiment 1~6

[0032] The preparation method of embodiment 1~6 is as follows:

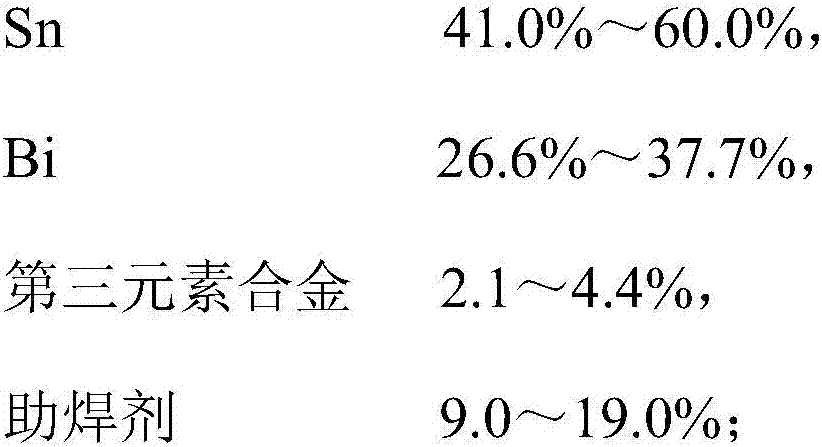

[0033] Table 1: The solder paste composition ratio of Examples 1-6

[0034]

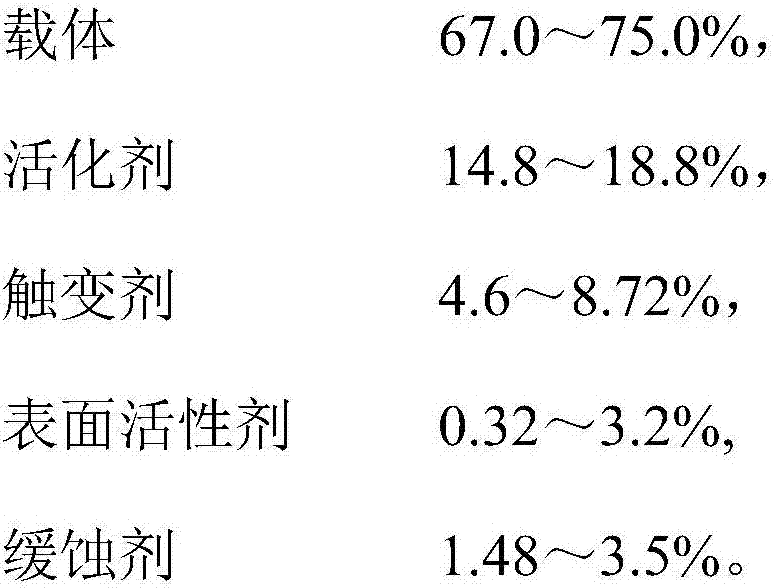

[0035] Table 2: Component distribution ratio of flux in the solder paste of Examples 1-6

[0036]

[0037]

Embodiment 1

[0039] A. Mix the activator and carrier evenly in proportion, and heat to 110°C to completely dissolve to make primary mixture a, cool to room temperature for later use;

[0040] B. Mix the film-forming agent and the surfactant evenly, and heat to 105°C to completely dissolve to obtain the primary mixture b;

[0041] C. Add corrosion inhibitor to the primary mixture b, stir to dissolve completely and cool to room temperature, then add the above primary mixture a, stir evenly to make flux, and place it in an environment with a temperature of 2°C for later use;

[0042] D. After the prepared flux is left to stand for 24 hours, add Sn-Bi solder powder and the third element alloy powder except aluminum powder according to the weight ratio, mix and stir in the vacuum disperser at 125°C for 3.7H, and cool down After reaching 45°C, add nano-aluminum powder and stir evenly, and refrigerate at 4°C to obtain a finished solder paste.

Embodiment 2

[0044] A. Mix the activator and the carrier evenly in proportion, and heat to 120°C to completely dissolve to make primary mixture a, cool to room temperature for later use;

[0045] B. Mix the film-forming agent and the surfactant evenly, and heat to 100°C to completely dissolve to obtain the primary mixture b;

[0046] C. Add corrosion inhibitor to the primary mixture b, stir to dissolve completely and cool to room temperature, then add the above primary mixture a, stir evenly to make flux, and place it in an environment with a temperature of 2°C for later use;

[0047]D. After the prepared flux is left to stand for 24 hours, add Sn-Bi solder powder and the third element alloy powder except aluminum powder according to the weight ratio, mix and stir and evaporate in the vacuum disperser at 135°C for 4H, and cool down to After 45°C, add nano-aluminum powder and stir evenly, and refrigerate at 1°C to obtain a finished solder paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com