A microporous aerator

A technology of microporous aerator and air inlet, which is applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc. Achieve the effect of improving aeration efficiency, prolonging service life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

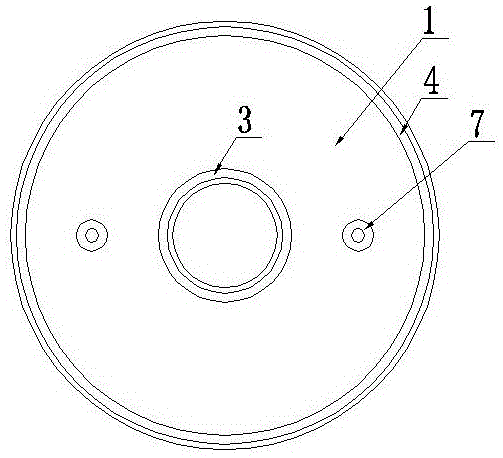

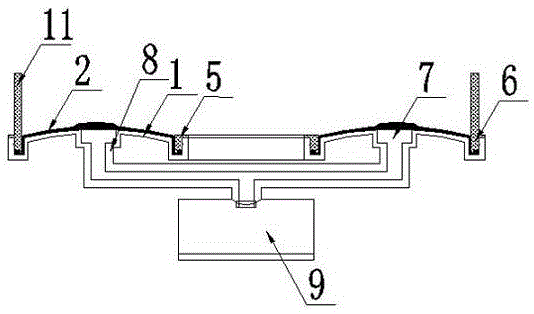

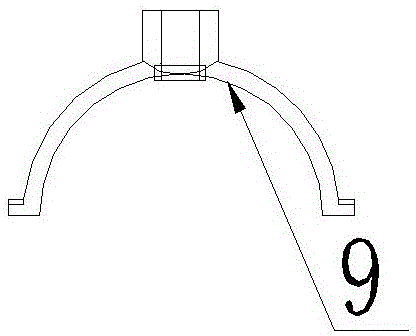

[0018] Such as Figures 1 to 4 As shown, the present invention includes a support disc 1 and a membrane 2 covering the support disc. The support disc 1 is a circular curved disc body with a hollow center, and the inner ring and the outer ring are respectively provided with inner pressure grooves 3 and outer pressure grooves 4 with U-shaped cross-sections. An inner pressure ring 5 and an outer pressure ring 6 corresponding thereto are respectively provided in the inner and outer pressure grooves. The disc body of the support disc 1 is provided with two air intake holes 7, and can also be provided with a plurality of them as required. A support base 8 is connected to the lower end of each air inlet 7 and communicates with the support base. The supporting bases 8 communicate with each other through pipes, and communicate with the saddle frame 9 below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com