Cast-in-situ bored pile and construction method thereof

A technology of bored piles and piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in mechanical equipment, waste of concrete, etc., to improve the quality of construction, improve quality, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

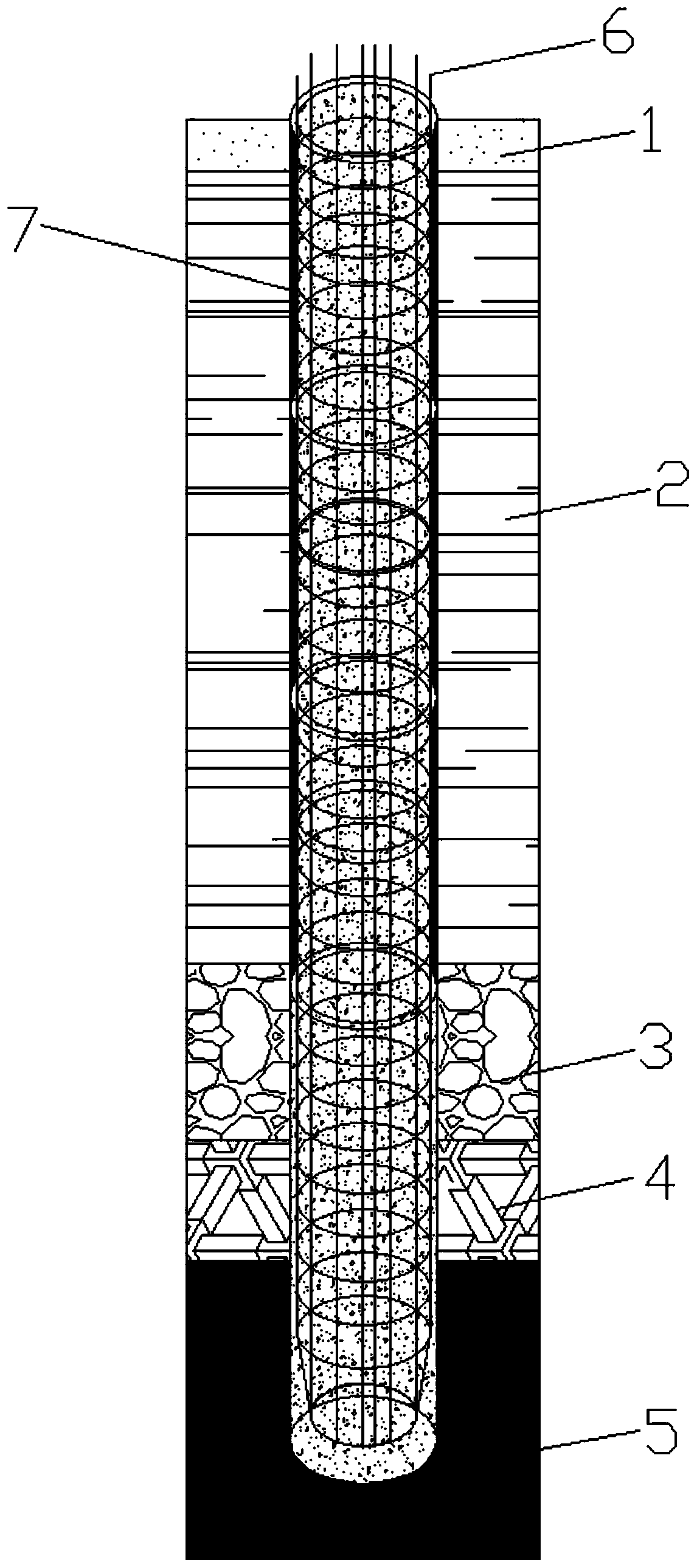

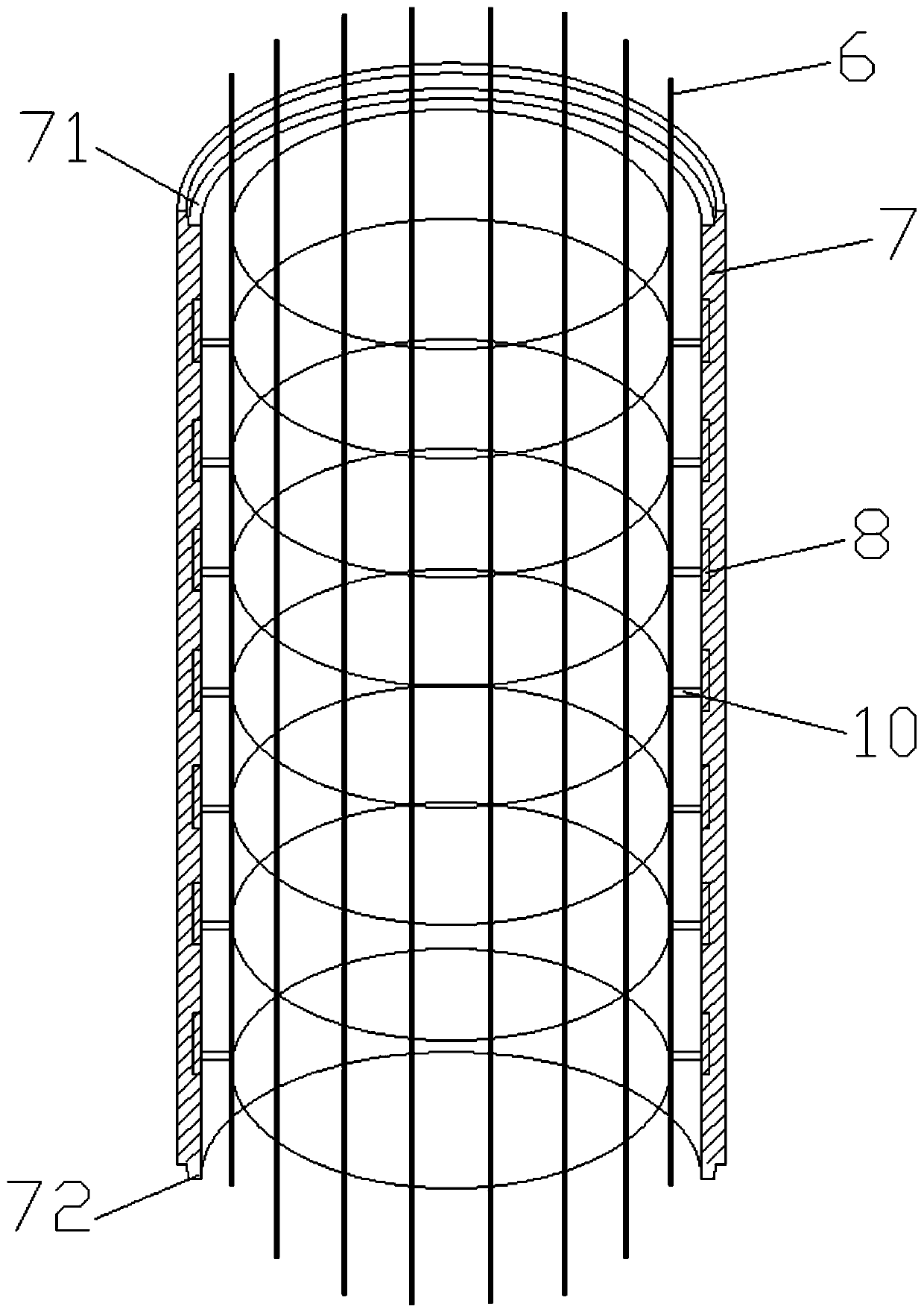

[0030] figure 1 It is a structural schematic diagram of the bored pile involved in an embodiment of the present invention. In this embodiment, the bored cast-in-place pile is an end-bearing pile with a diameter of 2 meters and a pile length of 40 meters, and the groundwater level is below the bottom of the pile. The order from top to bottom in the figure is: Miscellaneous fill layer 1, 2 meters thick; Silt layer 2, 20 meters thick; Strongly weathered rock layer 3, 3 meters thick; Medium weathered rock layer 4, 8 meters thick; Slightly weathered rock layer 5, The thickness is 12 meters. figure 2 It is a schematic diagram of a partial cross-sectional structure of a bored pile involved in an embodiment of the present invention. figure 2 shows the section structure of a cement circular pipe and the structure of the pile reinforcement cage where the joint circular pipe is located.

[0031] Please refer to figure 1 and figure 2 , the bored cast-in-place pile in the present i...

Embodiment 2

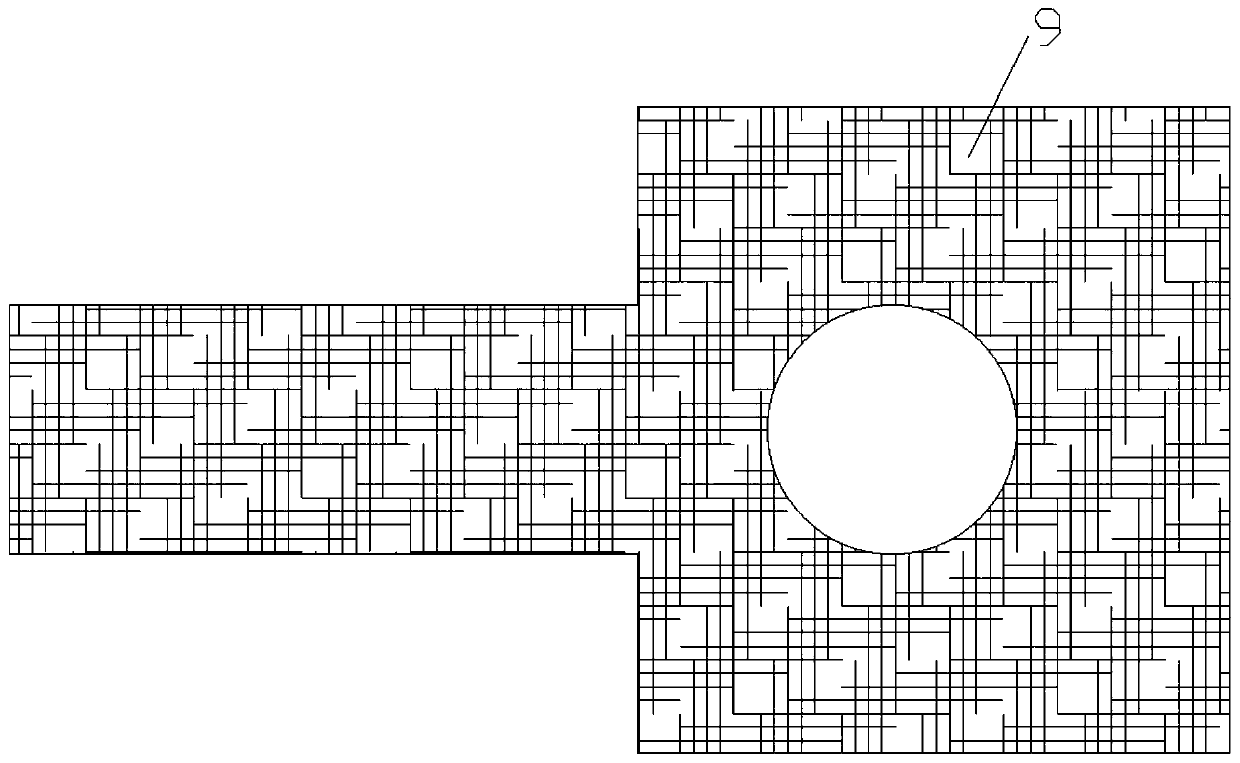

[0035] image 3 It is a schematic plan view of the construction platform involved in an embodiment of the present invention. Figure 4 It is a schematic flowchart of the construction method of the bored pile involved in one embodiment of the present invention.

[0036] In this embodiment, the construction method of the bored pile described in the first embodiment is introduced, and the construction method mainly includes the following steps:

[0037] Step S1: Carry out construction lofting on the pile site to determine the center of the pile site and the circumference line of the pile site.

[0038] Step S2: laying subgrade box slabs around the piles to form a construction platform 9 around the piles. The construction platform 9 is composed of a steel frame inserted in the mud layer and an upper roadbed box board, and each roadbed box board is connected together by a hinge. The middle of the construction platform 9 is where the pile holes are located, and one side of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com