Gravel pile with consolidated sand layer and reinforced concrete pipe joint, and construction method thereof

A reinforced concrete pipe and reinforced concrete technology, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problem that gravel piles cannot more effectively meet engineering needs, prevent water permeable holes from being blocked, and reduce the effect of pile body drainage. and other problems, to achieve the effect of good forming effect, ensuring pile quality, and improving the bearing capacity of foundation soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0043] The manufacturing process and transportation of prefabricated reinforced concrete pipe joints and spud cans, transportation of crushed stones, etc. will not be described repeatedly in this embodiment, and the embodiment of the structure related to the present invention will be mainly explained.

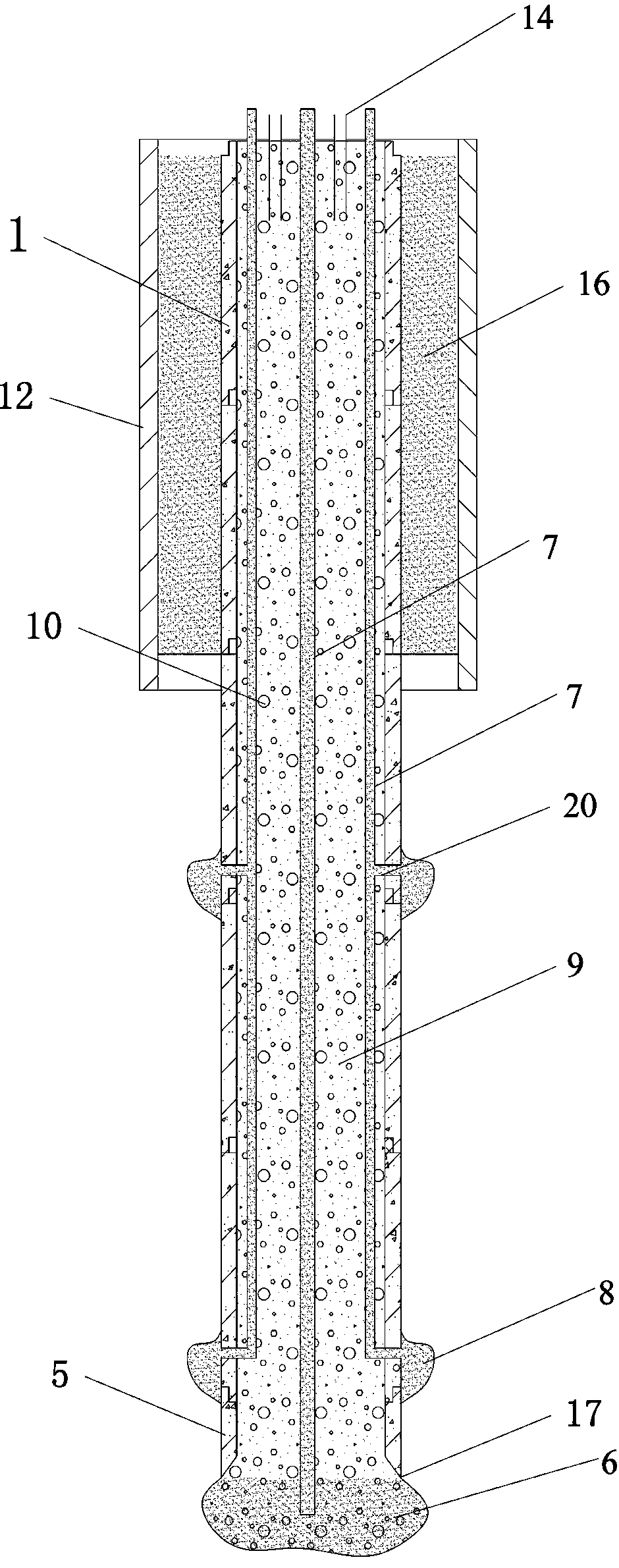

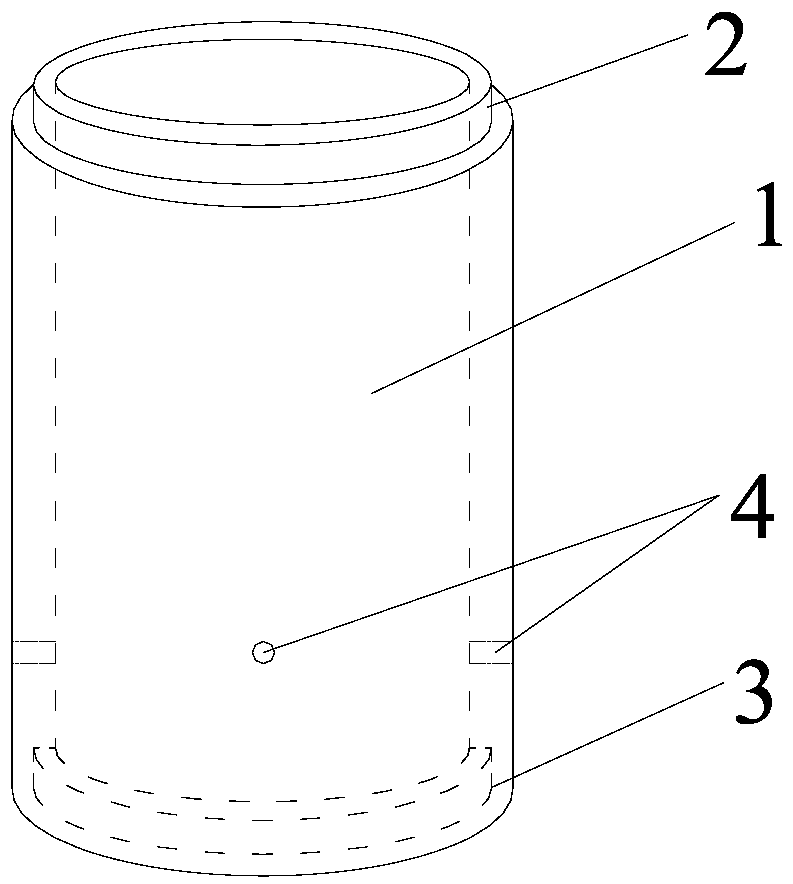

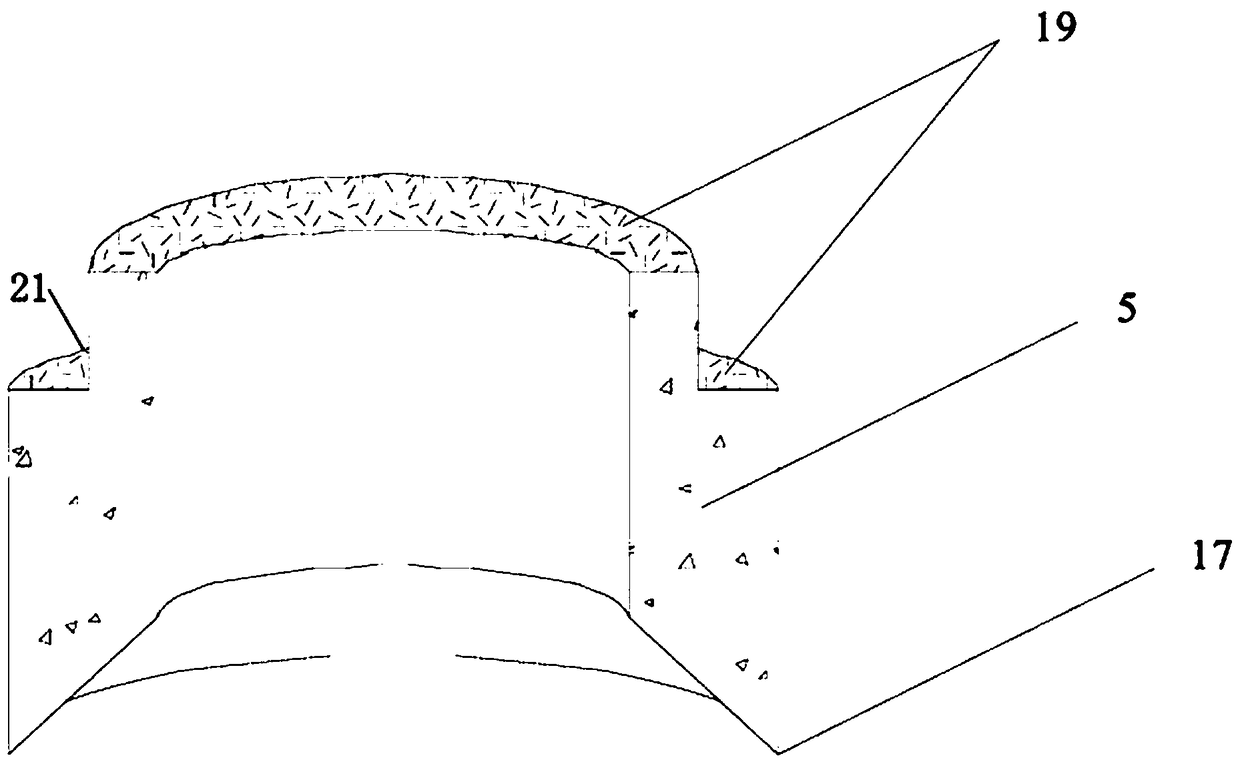

[0044] figure 1 It is a schematic diagram of a reinforced concrete pipe joint gravel pile with a sand layer consolidated after pressure grouting of the present invention; figure 2 It is a schematic diagram of a reinforced concrete pipe joint of the present invention; image 3 is a schematic cross-sectional view of the spud can of the present invention; Figure 4 It is a schematic diagram of the cross-section of the consolidated sand layer reinforced con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com