Double-head heating necking method and necking device thereof for thick-wall round tubes

A heating device and necking technology, which is applied in the field of thick-walled circular tube double-head heating and necking method and its necking device, can solve the problems of high labor cost, increased labor intensity, and easy occurrence of defective products, and achieve the degree of automation High, reduce labor intensity, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

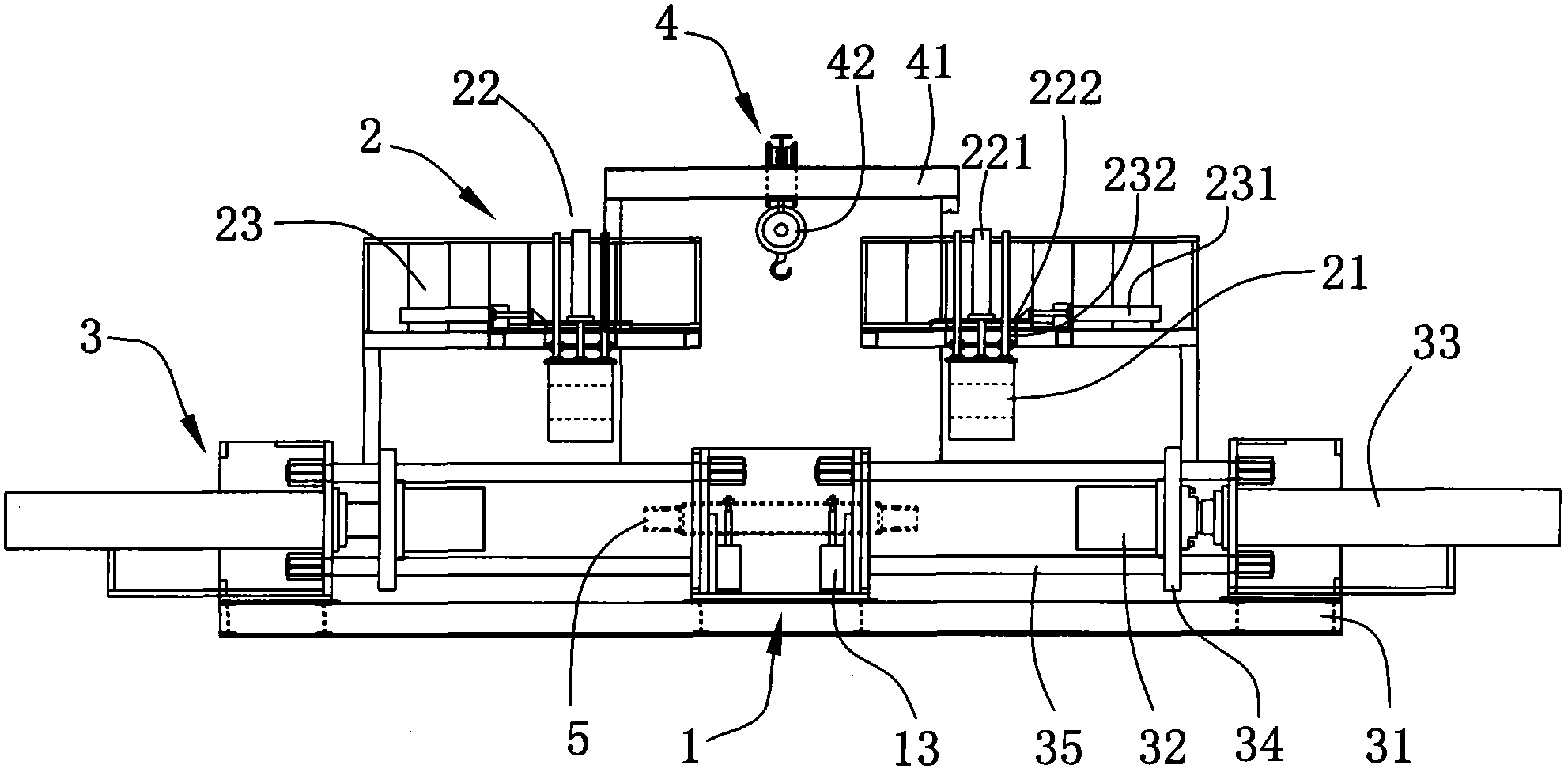

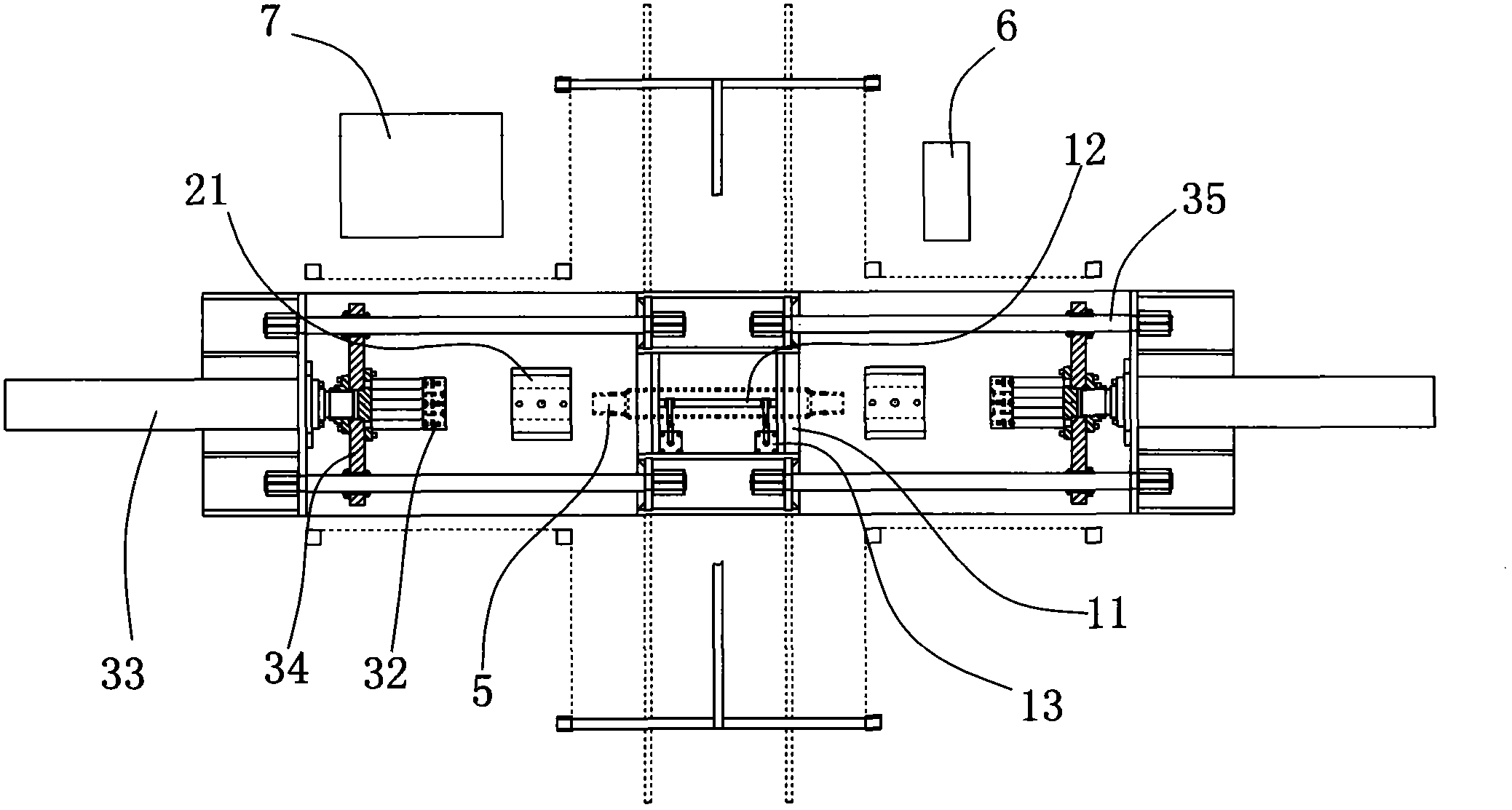

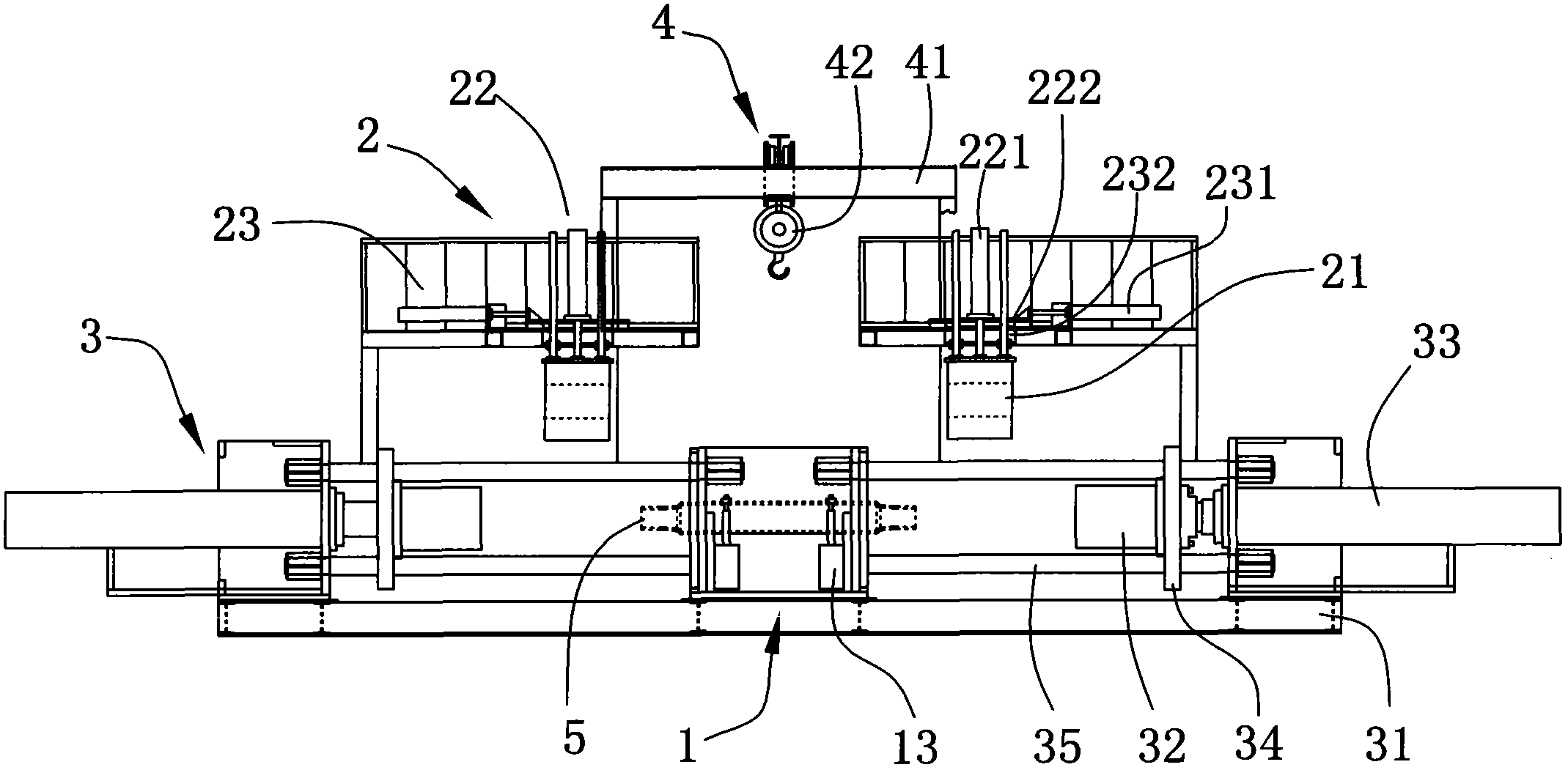

[0036] Example: see figure 1 and figure 2 , the embodiment of the present invention provides a thick-walled circular tube double-head heating necking method, which includes the following steps:

[0037] (1) clamping device 1 is set, and by controlling the work of this clamping device 1, to realize the metal pipe 5 of clamping required necking;

[0038] (2) heating device 2 is set, and by controlling the operation of this heating device 2, to realize heating the neck of the metal pipe 5 required to be necked;

[0039] (3) A pressure device 3 is set, and by controlling the work of the pressure device 3, the neck of the metal pipe 5 required to be necked is suppressed and necked;

[0040] (4) An automatic control system is provided, which is respectively connected with the clamping device 1, the heating device 2 and the pressure device 3, and controls their working states;

[0041] The steps (1) to (3) are in no sequence.

[0042] It also includes the steps of:

[0043] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com