Material tensile real constitutive curve testing technology

A curved and realistic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high computational cost, many iterations, and significant impact of compression simulation, and achieve ideal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

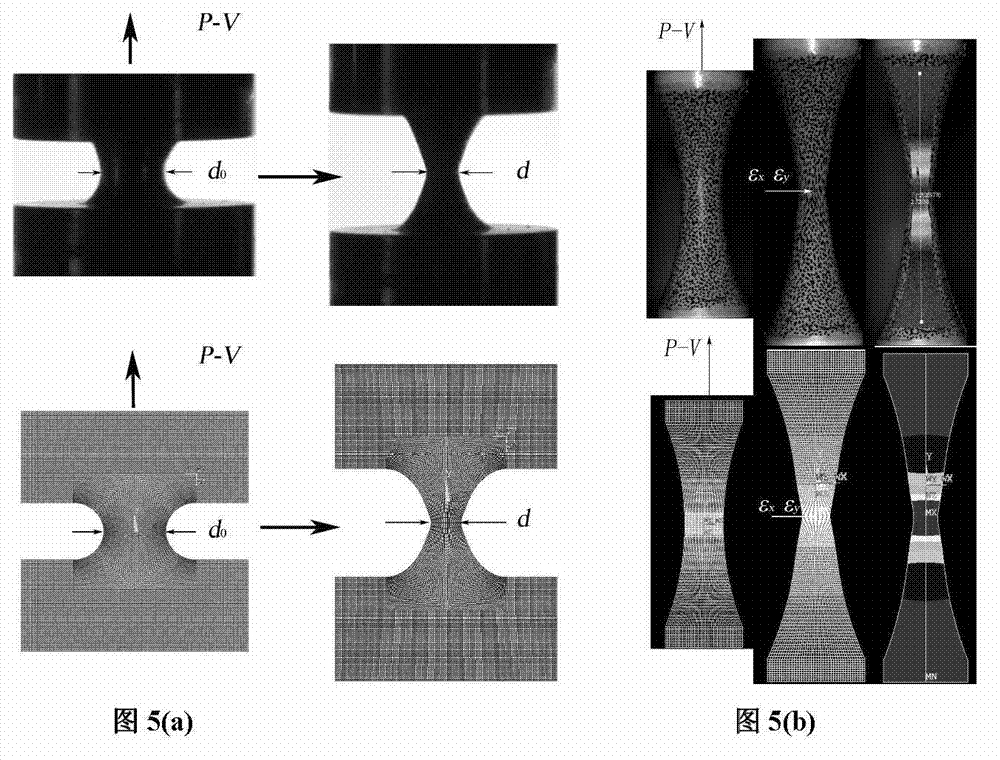

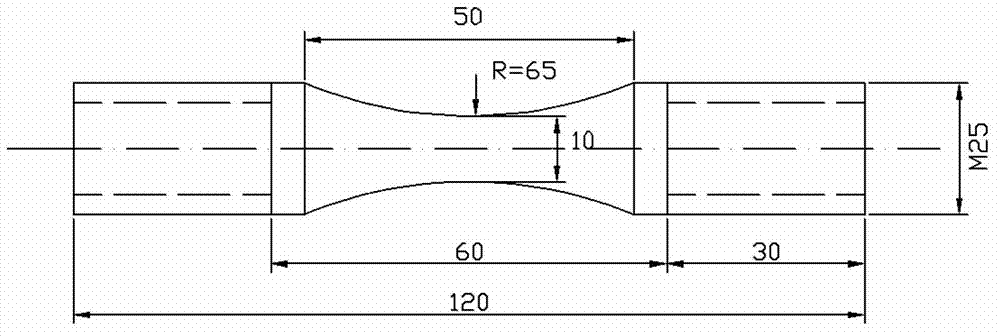

[0040] Taking 304 stainless steel as an example to further illustrate the specific implementation method of the technical solution of the present invention. Tensile test and VIC-3D optical measurement system such as Figure 4 As shown, the finite element simulation is carried out with ANSYS11.0. Figure 5 It is the comparison chart of funnel sample necking phenomenon test and finite element simulation, and the comparison chart of finite element simulation deformation field and optical measurement deformation field, Image 6 is the comparison result of the test load-displacement curve and the simulated load-displacement curve, Figure 7 is the optical measurement and simulation results of the minimum cross-sectional diameter d-displacement V curve at the necking root of the sample, Figure 8 is the photometry and simulation results of the shape curve of the funnel root at a certain loading moment of the sample, Figure 9 It is the result comparison of the real tensile consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com