Forming device and method for precise subregional temperature control to realize tube end shrinking and thickening

A sub-area and necking technology, which is applied to forming tools, reducing greenhouse gases, manufacturing tools, etc., can solve the problems of heating the mold for a long time, increasing the weight of parts, and hindering the flow of materials, so as to improve the strength and utilization of materials. The effect of reducing the weight of parts and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

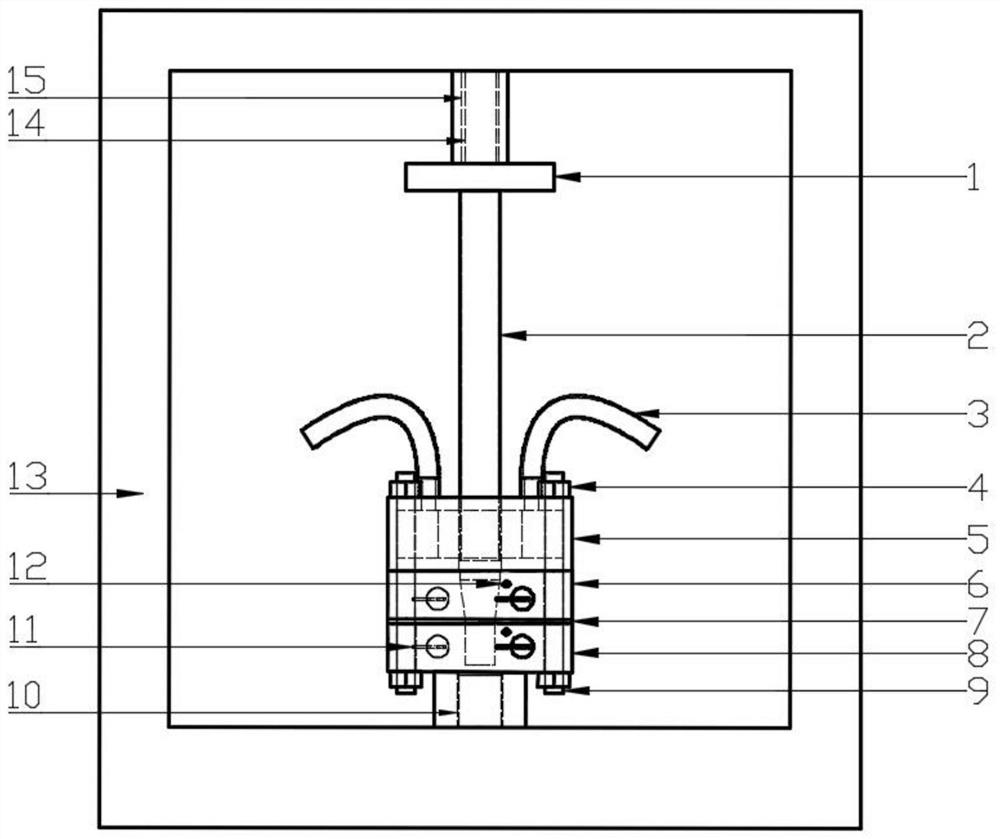

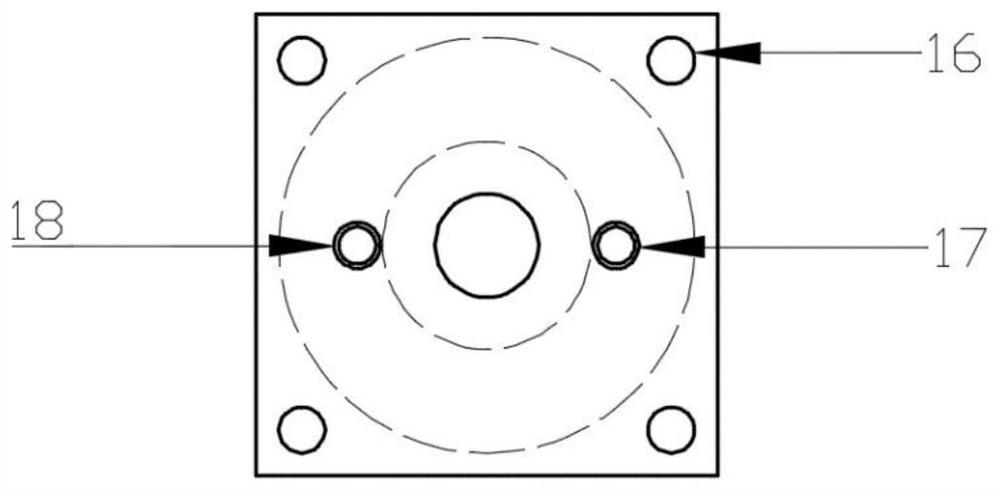

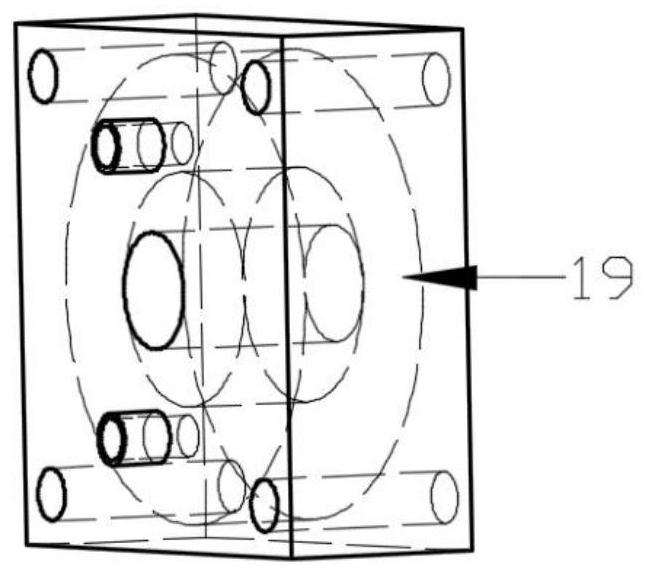

[0035] like Figure 1-6 As shown, this embodiment provides a forming device for accurately controlling the temperature in different regions to realize the thickening of the necking of the pipe end. Among them, the universal testing machine 13 is used as the main power source to generate a pressing force that pushes the pusher 1 to form the tube blank 2 . The threaded hole 15 on the top of the universal testing machine 13 is used to fix the pusher 1, the water inlet 17 and the water outlet 18 of the cooler 5 are respectively connected with the hose 3, and the screw 9 is used to connect the cooler 5, the shrinking die 6, and the heat insulating plate. 7 and thickening die 8, the threaded hole 10 at the bottom of the universal testing machine 13 is used to fix the thickening die 8, the pusher 1 is used to realize the feeding of the tube blank 2, and the cooler 5 is used to cool the necking die 6 and thickening The temperature of the tube blank other than the die 8, the shrinking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com