Vertical continuous oil pipe blowout preventer

A blowout preventer and tubing technology, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc., can solve problems such as personnel trauma, and achieve the effects of facilitating operation, semi-sealing reliability, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

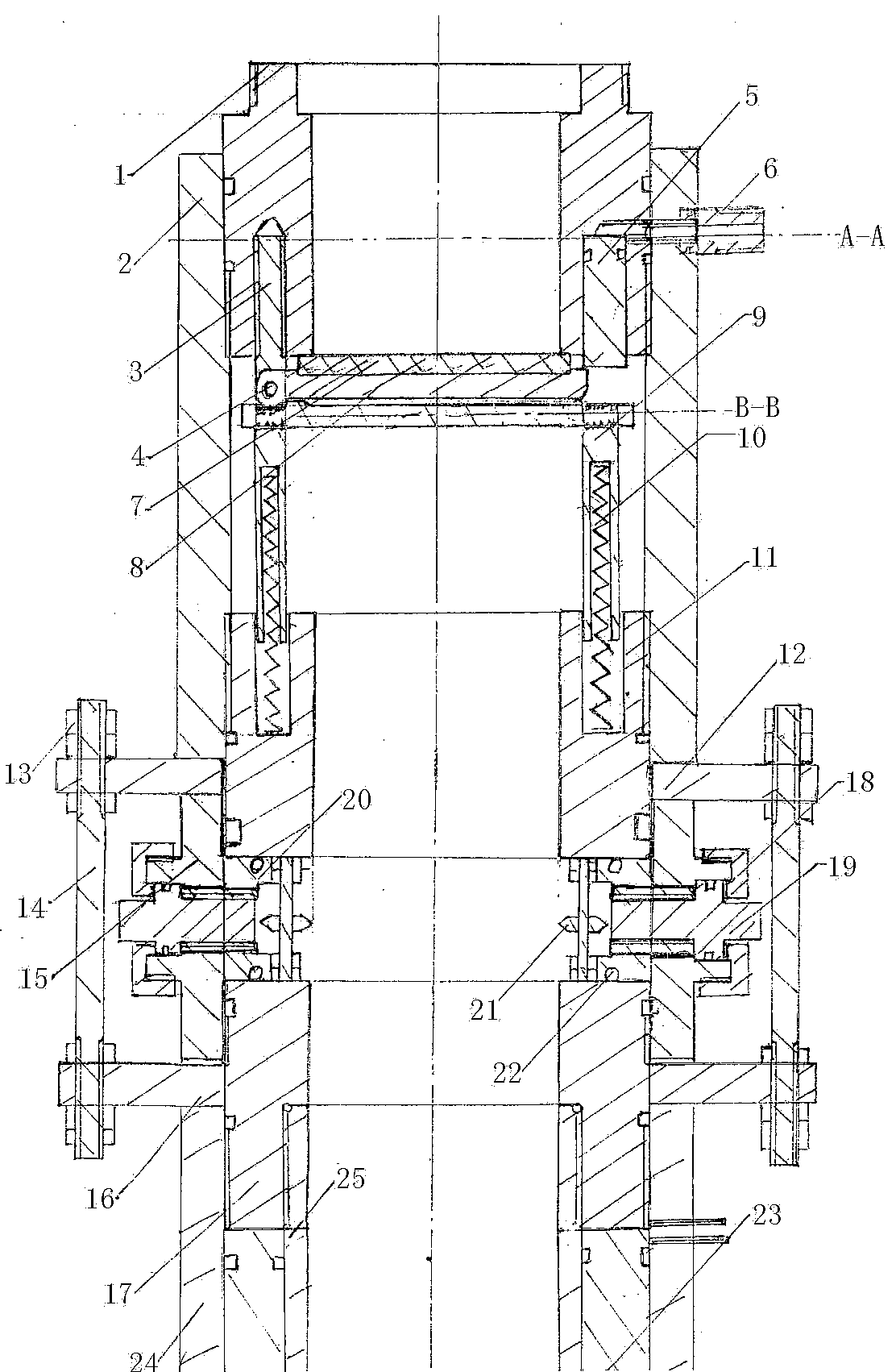

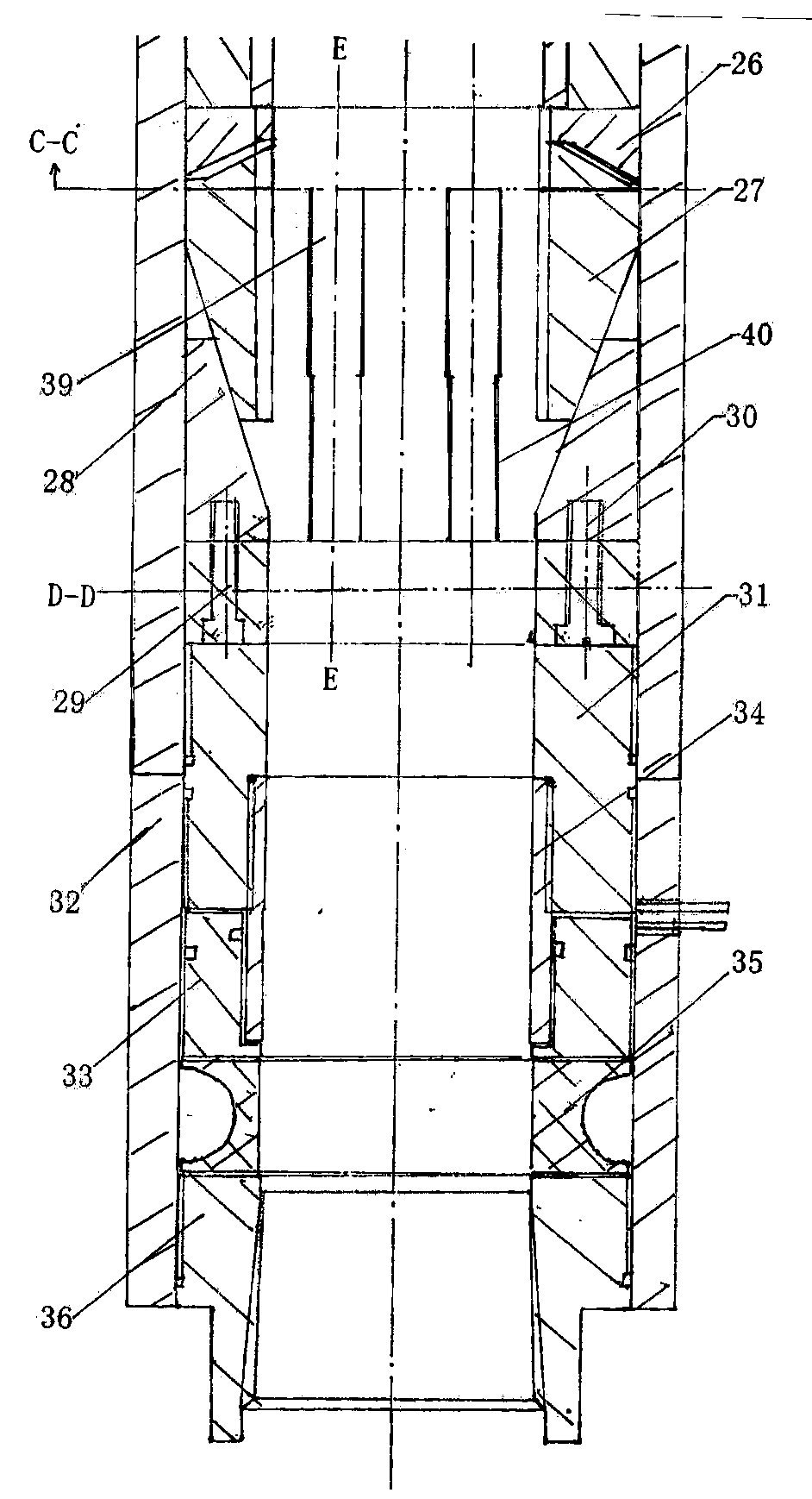

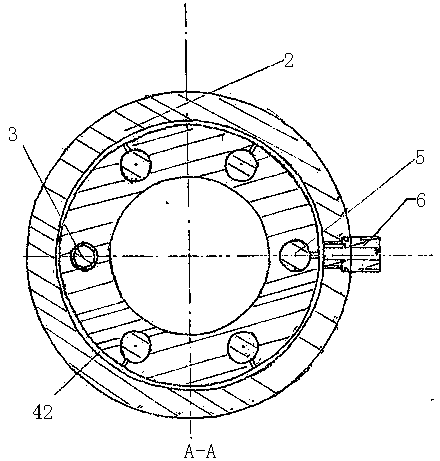

[0013] refer to Figure 1-7 , the vertical coiled tubing blowout preventer consists of four parts from bottom to top: half seal, suspension, cutting and full seal. The half seal part includes lower joint 36, annular half seal 35, seat seal inner sleeve 34, Sealed piston 33, half-sealed outer cylinder liner 32 and half-sealed connecting ring 31, the suspension part includes a tapered fixed ring 29, connecting bolts 30, seat clamping cones 28, return spring seat 40, return spring sleeve 39, slips 27, Slip return spring 41, slip holder 26, seat card sealing cylinder 24, seat card sealing inner sleeve 25, seat card piston 23 and suspension connecting ring 17, the cutting part includes lower flange 16, pressure ball 22, cutter 21, Cutting tool holder 20, feed screw 19, feed limit pressure ring 18, cutting swivel 15, bolt 14, upper flange 12 and nut 13, the fully sealed part includes upper joint 1, fully sealed outer cylinder liner 2, Hydraulic oil exchange tank 42, ram fixing bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com