Automatic production line for packaging thin film roll materials

An automated production line and film roll technology, applied in the field of film roll stretching, can solve problems such as high labor intensity, product damage, and occupation of human resources, and achieve the effect of improving safe operation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

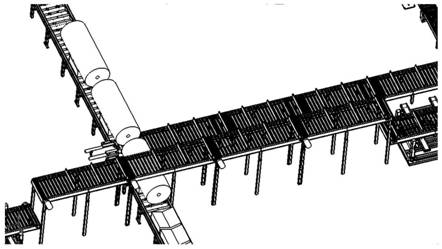

[0034] The automatic production line that is used for film coil packaging of the present invention, its preferred embodiment is:

[0035] Including sequentially connected conveying and loading station, weighing and measuring station, packaging cutting and laminating station, end cover installation station, label pasting station, stacking and unloading station, the end cover installation station One side is equipped with an end cover assembly station;

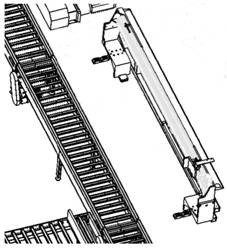

[0036] The conveying and feeding station includes two chain-plate conveying lines, and the outer end of each chain-plate conveying line is respectively equipped with a horizontal coil material conveying line, wherein a chain-plate conveying line at the far end is bypassed by a lifting conveying platform Another chain-plate conveying line for coil material transverse conveying line;

[0037] The coil material transverse conveying line is provided with at least six coil material buffer positions and a partition to prevent the coi...

specific Embodiment

[0054] 1. Production line layout

[0055] Such as figure 1 As shown, the roll automatic packaging line consists of the following parts:

[0056] 1. Chain plate conveying line

[0057] 2. Weigh the platform and measure the length of the coil (on-line measurement)

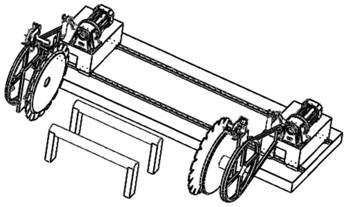

[0058] 3. Packaging film feeder, film rolling mechanism and adhesive tape (including loading and unloading mechanism)

[0059]4. Cardboard, foam partition feeding mechanism; cardboard, foam partition packaging mechanism (on-line packaging)

[0060] 5. Automatic labeling machine

[0061] 6. Palletizing walking ground rail robot

[0062] 2. Workflow

[0063] The solution consists of a fully automatic six-axis manipulator, a truss manipulator, and a transport chain. The camera ccd system is used to identify the length of the roll, the manipulator grabs it, and the AGV transports to complete the entire loading action.

[0064] workflow such as figure 2 shown.

[0065] 3. Production line takt calculation

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com