Automatic paper-spreading machine

A paper laying and automatic technology, which is applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of inability to achieve consistency and accuracy, affect the overall appearance of the product, and uneven products, and achieve the perfect paper laying process , reduce industrial accidents, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

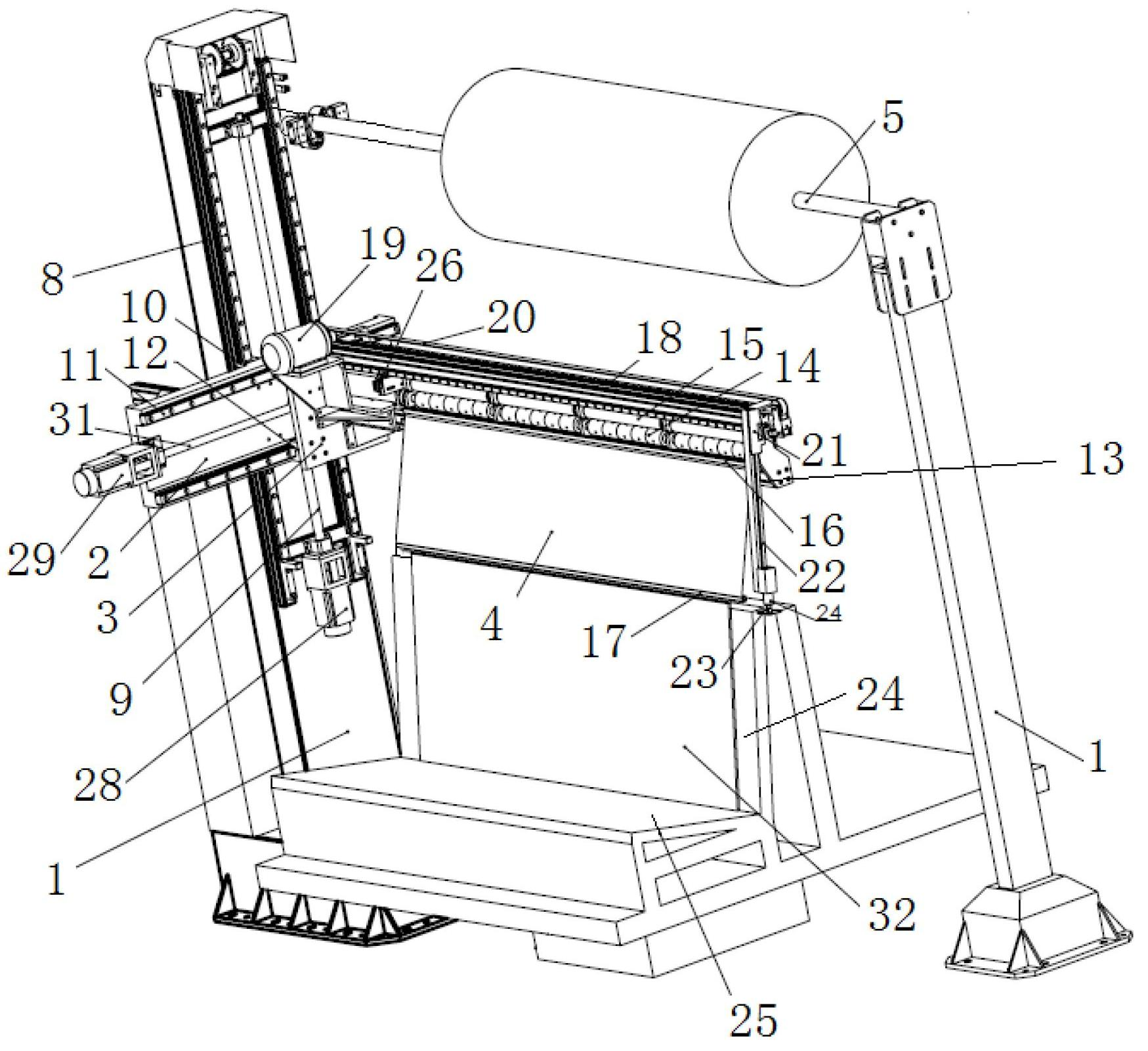

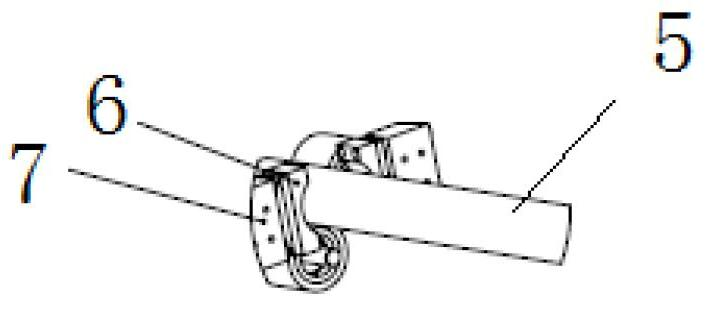

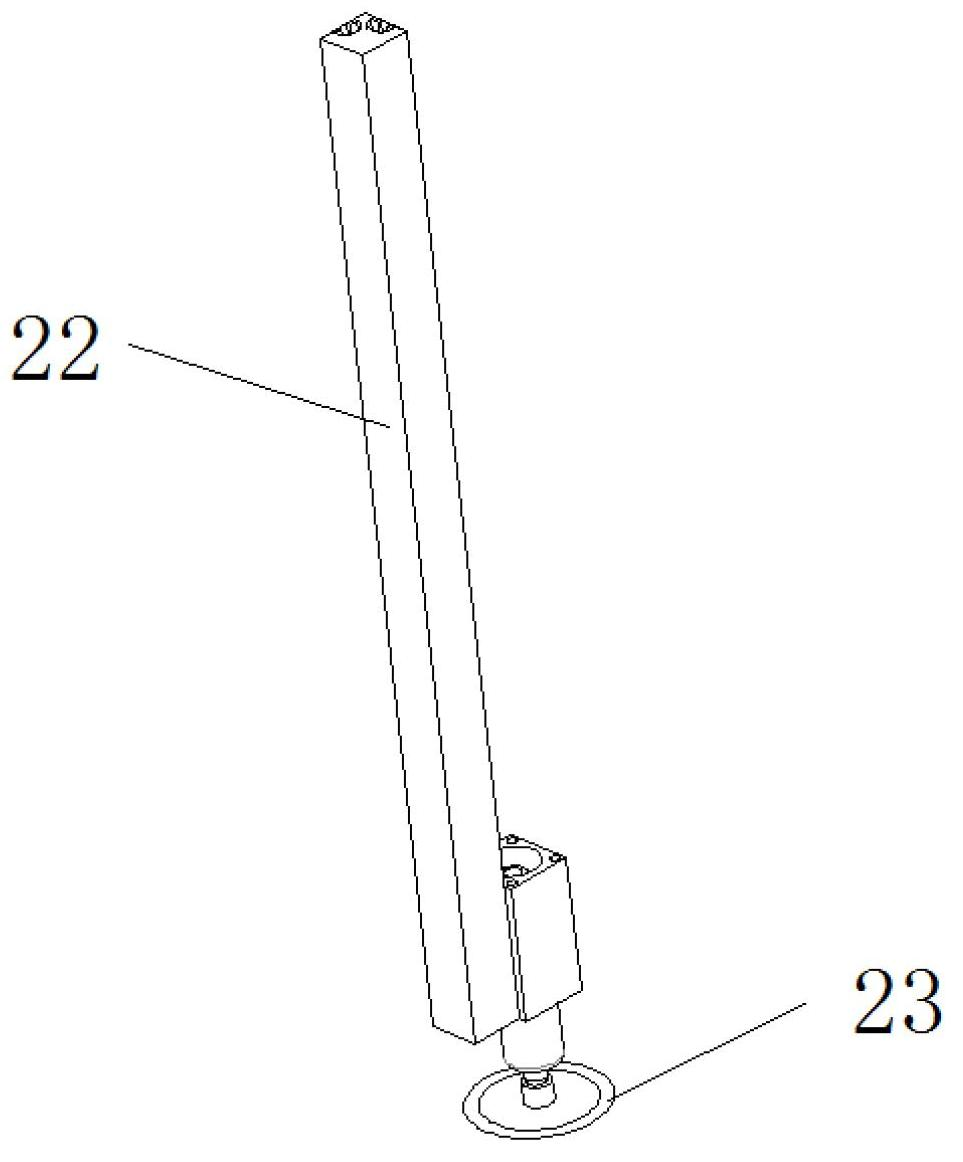

[0022] Such as Figure 1~Figure 3 An automatic paper laying machine is shown, including two uprights 1, an elevating sliding table 2 arranged on one of the uprights 1, a horizontal sliding table 3, a paper feeder, a paper guide plate 4 arranged under the paper feeder, and a paper cutter , the transverse sliding platform 3 is arranged on the lifting sliding platform 2, and one end of the paper feeder is connected to the described transverse sliding platform 3. A paper roll shaft 5 is arranged between the tops of the two upright columns 1, a paper roll shaft is sleeved on the paper roll shaft 5, and a rotation brake mechanism is arranged on the paper roll shaft. The rotating brake mechanism includes two brake blocks 6 and two brake cylinders 7 that respectively control the expansion and contraction of the two brake blocks 6. The brake block 6 is provided with arc grooves, and the arc grooves of the two brake blocks 6 are merged to form a joint with the roll paper. Cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com