Packaging machine capable of automatically mounting packaging belt

An automatic installation and strapping technology, which is applied in the field of strapping machines, can solve the problems of heavy strapping, prone to work-related accidents, and labor-intensive problems, and achieve the effects of reducing labor intensity, reducing the probability of occurrence, and reducing work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

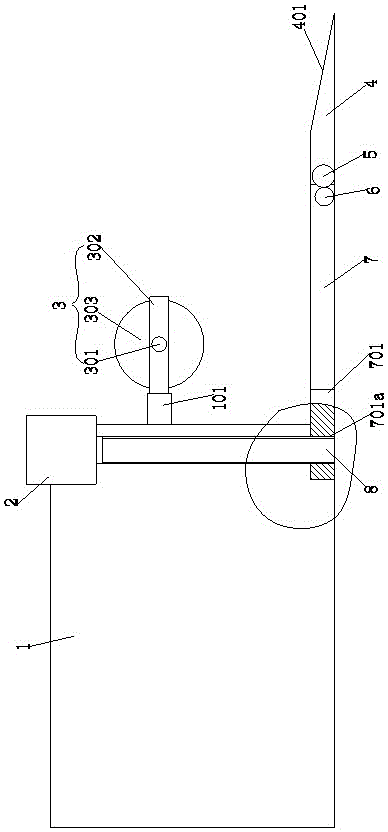

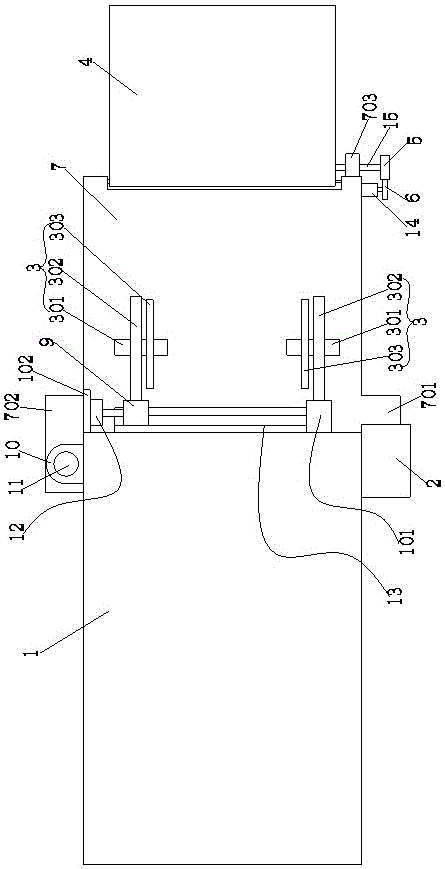

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] like Figures 1 to 2 As shown, a kind of packing machine of the present invention automatically installs packing belt, it comprises packing machine body 1; The side wall of described packing machine body 1 is provided with packing tape clamping mechanism; Described packing tape clamps A slide plate 7 is provided directly below the mechanism; a left convex plate 701 and a right convex plate 702 are respectively provided on the left and right sides of the slide plate 7; a threaded hole 701a is provided on the upper surface of the left convex plate 701; the baler body The left and right side walls of 1 are respectively fixed with a lifting motor 2 and a guide sleeve 10; the right convex plate 702 is fixed with a guide shaft 11 that matches the guide sleeve 10; the top of the guide shaft 11 passes through from bottom to top Guide sleeve 10; the output end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com