Oil cylinder drive type feeding device for multi-station internal thread tapping equipment for sleeves

An internal thread and multi-station technology, applied in metal processing equipment, thread cutting device, metal processing, etc., can solve problems such as low degree of automation, low production efficiency, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

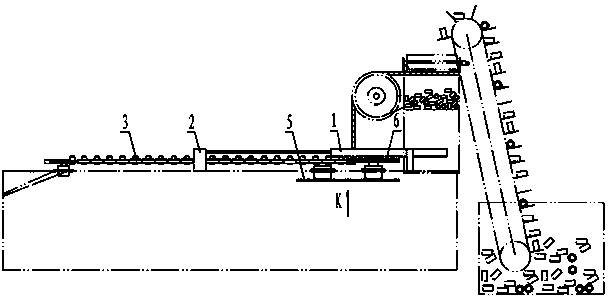

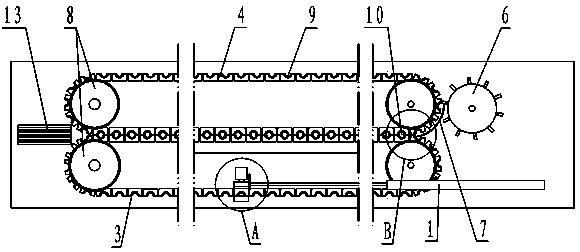

[0020] See Figure 1, figure 2 , the present invention includes a driving cylinder 1, a clamping unit 2, a driving chain assembly 3, a driven chain assembly 4, a gear transmission unit 5 and a dial wheel 6, and the driving cylinder 1 is fixed on the base of the sleeve internal thread tapping equipment On the telescopic arm, a clamping unit 2 is installed, the clamping unit 2 is matched with the driving chain assembly 3, and the driving chain assembly 3 is matched with the driven chain assembly 4 to realize the transfer of the sleeve workpiece 11 from the automatic sorting station to the For the delivery of the tapping station, the gear transmission unit 5 is fitted with the driven chain assembly 4 and the dial wheel 6 .

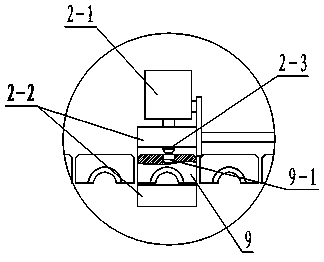

[0021] see figure 2 , image 3 , Figure 4 , the clamping unit 2 of the present invention includes a clamping oil cylinder 2-1 and a clamping block 2-2, the telescopic arm of the clamping oil cylinder 2-1 is fitted with the clamping block 2-2, and the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com