Special-shaped necking die

A special-shaped, mold technology, applied in the field of stamping molds, can solve the problems of high difficulty in forming process, difficult to accurately locate, large size and weight, etc., and achieve the effect of meeting product technical requirements, high positioning accuracy, improving product quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

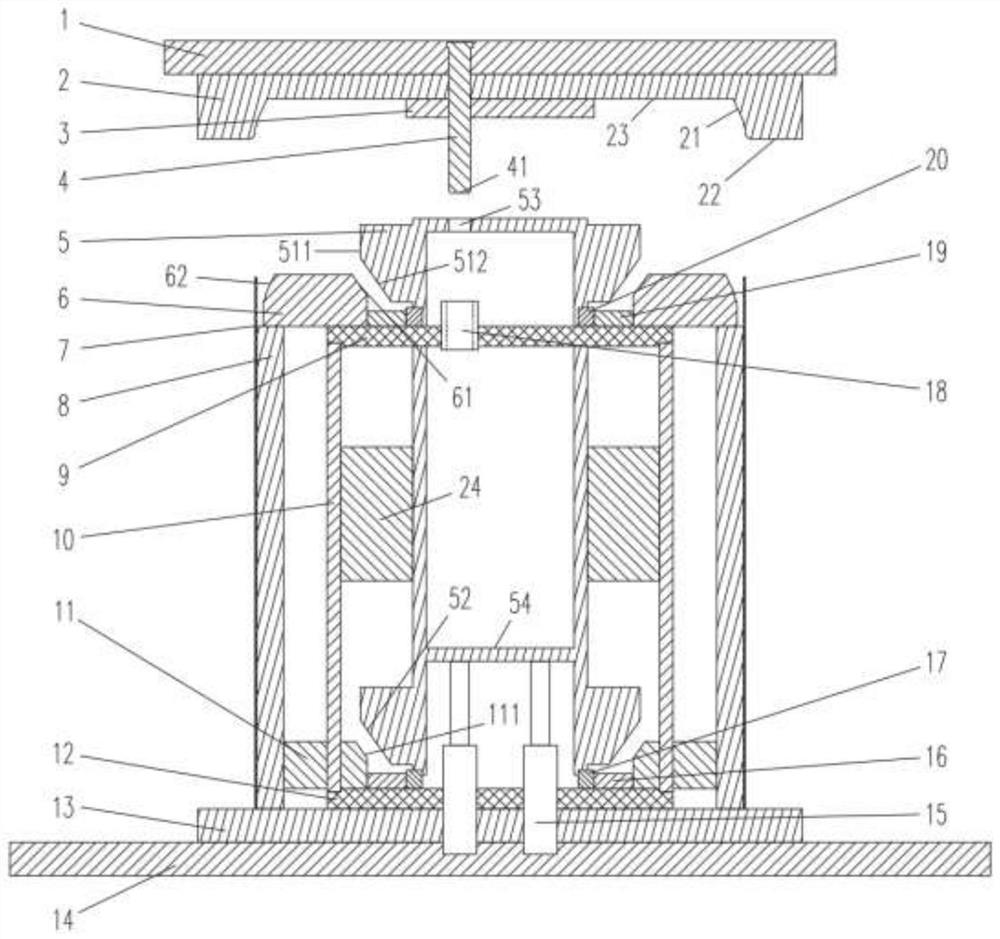

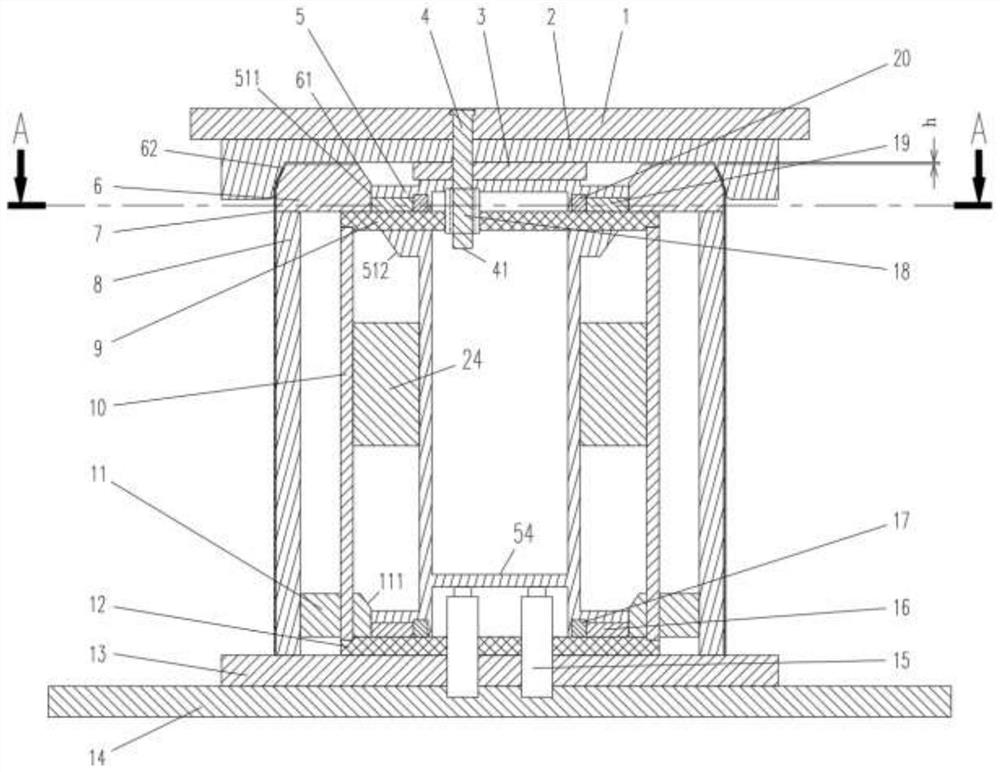

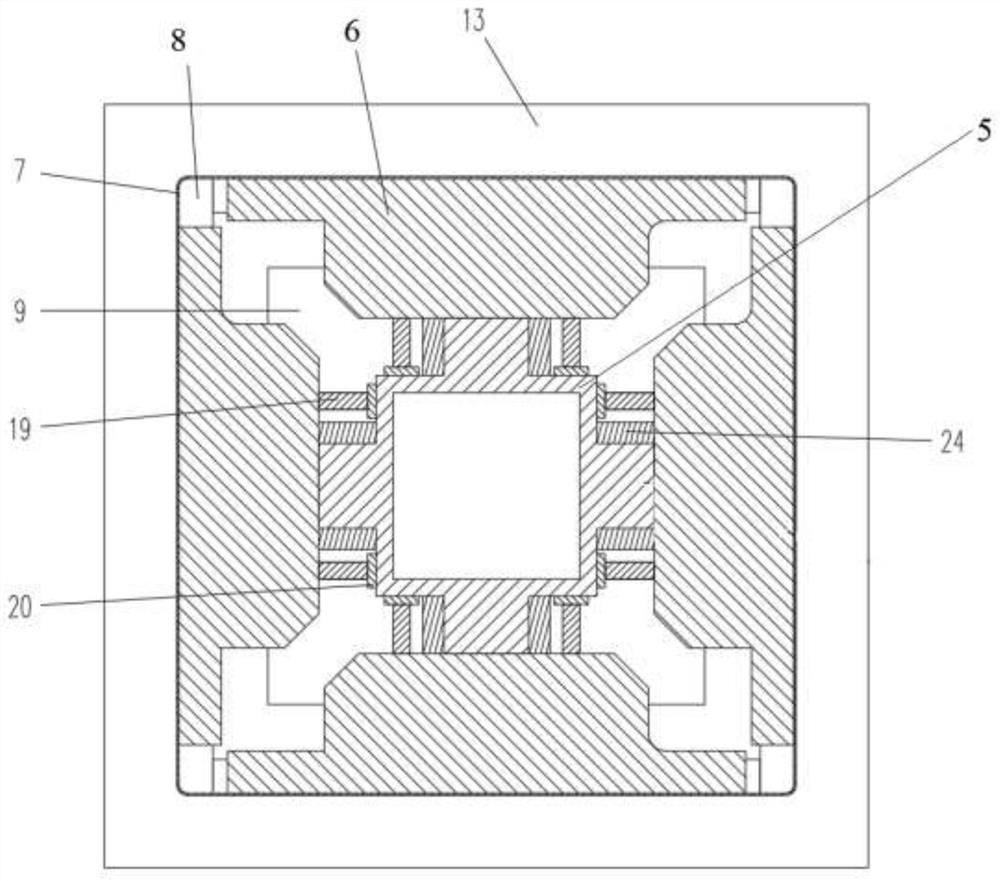

[0040] Embodiment 1, a kind of special-shaped necking mold, such as Figure 1~3 As shown, including upper mold and lower mold. The lower mold is located directly below the upper mold and works in cooperation with the upper mold. When the stretch extrusion die is not working or is in the initial state, the upper die and the lower die are separated, such as figure 1 shown.

[0041] The upper mold includes an upper back plate 1 , a die 2 , an upper mold pressing block 3 and an upper mold guide post 4 .

[0042] The outer bottom surface of the die 2 is fixedly connected with the lower surface of the upper back plate 1, and the inner cavity of the die 2 is a trapezoidal inner cavity with a narrow bottom and a wide top, and an upper mold pressing block is fixedly arranged at the center of the bottom surface 23 of the trapezoidal inner cavity of the die 2 3. The cross section of the upper mold pressing block 3 is much smaller than the bottom surface 23 of the table-shaped inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com