Intelligent crust breaking system and control method thereof

A shelling system and intelligent technology, applied in the field of intelligent shelling system and its control, can solve the problems of low service life of the hammer head, inability to reduce the system pressure, large gas consumption, etc., so as to reduce the labor intensity and workload of workers, and improve the Yield and quality, the effect of improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

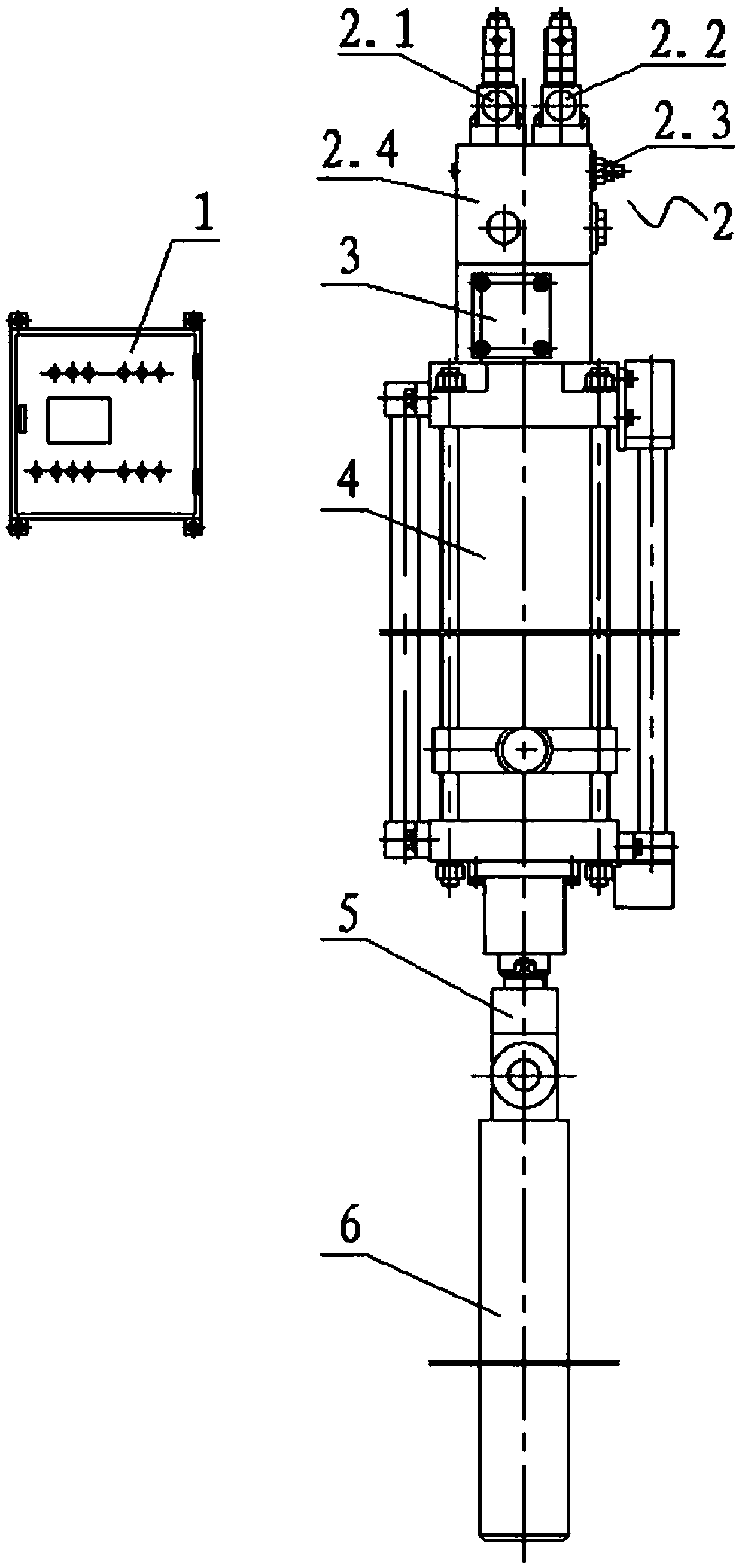

[0013] Attached below figure 1 , 2 The specific embodiment of the present invention will be further described.

[0014] Intelligent shelling system, including control cabinet 1, combination valve 2, signaling adjustment device 3, shelling cylinder 4 and shelling hammer 6; combined valve 2 includes reversing valve 2.1, pressure valve 2.2, pressure adjustment knob 2.3 and valve Body 2.4, reversing valve 2.1 and pressure valve 2.2 protrude from the top of valve body 2.4, and pressure adjustment knob 2.3 protrudes from one side of valve body 2.4; the sending adjustment device 3 is installed on one side of valve body 2.4, and valve body 2.4 is installed On the rear end cover of the shelling cylinder 4, the shelling hammer head 6 and the piston rod of the shelling cylinder 4 are hinged through the fork joint 5; the combination valve 2 is connected with the control cabinet 1 by wire.

[0015] The control cabinet 1 is independently installed on the wall near the electrolytic tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com