On-line identification method for concentration signal of aluminum oxide in electrolyte in aluminum electrolysis cell

A technology of inner electrolyte and aluminum electrolytic cell, which is applied in the field of online identification of alumina concentration signal in the electrolyte of aluminum electrolytic cell, which can solve the problems of limited sensor life, high requirements for equivalent circuit selection, error, etc., to reduce the anode effect coefficient, improve current efficiency, and realize the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

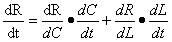

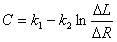

[0027] In a 200kA prebaked aluminum electrolysis series in an aluminum plant, 1# and 2# electrolytic cells were selected to identify the alumina concentration, and the anode was lifted every 3 hours, and the voltage change data of the cell was recorded to identify the alumina concentration, and the electrolyte was sampled , to analyze the alumina concentration in the electrolyte. The anode moves about 4mm, the process lasts for 2 minutes, record △L 1 、△R 1 , electrolyte sampling analysis alumina concentration C 1 , restore the polar distance; after a period of time, raise the anode again about 4mm, last for 2 minutes, and record △L 2 、△R 2 , electrolyte sampling analysis alumina concentration C 2 , restore the pole distance, and calculate the calibration constant k 1 、k 2 . 1# slot record result:

[0028] △L 1 △R 1 C 1 △L 2 △R 2 C 2 0.4121cm 5.06×10 -7 Ω 3.08% 0.4803cm 5.89×10 -7 Ω 3.14%

[0029] Then, 1# slot

[0030]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com