Method for improving corrosion resistance of powder coating

A powder coating and anti-corrosion technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of insufficient, unusable, easy to break, etc., to reduce the cost of use, reduce the thickness of the coating film, and achieve high anti-corrosion. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

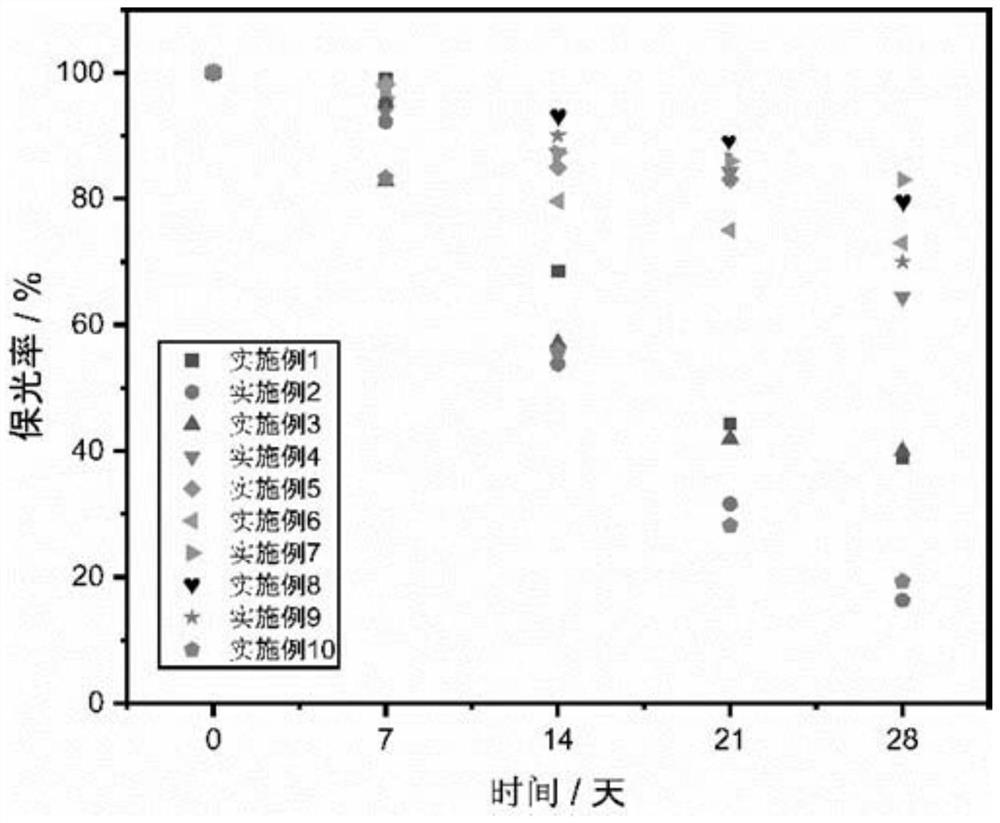

Embodiment 1

[0034] Graphene and zinc phosphate are added to the raw materials of polyester / TGIC powder coating in the mass ratio of 0.5% and 1.0% respectively, and mixed uniformly according to the processing step 1, and the prepared mixture is obtained according to the processing steps 2 and 3 Anti-corrosion powder coating with median particle size (D50, V)≤40μm.

Embodiment 2

[0036] Graphene and zinc phosphate are added to the raw materials of polyester / epoxy hybrid powder coatings in an amount of 0.5% and 8.0% by mass respectively, and mixed uniformly according to processing step 1, and the prepared mixture is processed according to processing step 2 and 3 Prepare an anti-corrosion powder coating with a median particle size (D50, V) ≤ 40 μm.

Embodiment 3

[0038] Add nano-clay and zinc phosphate to the raw materials of polyurethane powder coatings in the mass ratio of 6.0% and 2.0%, respectively, and mix them uniformly according to processing step 1, and the prepared mixture is obtained according to processing steps 2 and 3. Anti-corrosion ultra-fine powder coating with particle size (D50, V)≤22μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com