Method for early warning and inhibiting on-line anode effect of aluminum electrolysis cell

An anode effect and aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of insufficient forecasting, achieve energy-saving greenhouse gas, and realize the effect of low-voltage non-effect production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

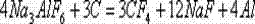

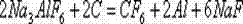

[0030] Open holes in the flue of a single aluminum electrolytic cell to collect gas. The gas enters the gas analyzer through filtration and drying. The gas analyzer conducts online continuous analysis of the gas composition and obtains the CF in the flue gas in real time. 4 concentration, and communicate the analysis results to the aluminum electrolytic cell control system.

[0031] When CF 4 When the concentration is zero, the electrolyzer operates normally, when CF 4 When the concentration mutation is not zero, that is, the minimum resolution of the detection equipment, such as: 0.01ppm, it can be judged that there has been an electrolytic side reaction at this time, and the overall or local alumina concentration of the electrolytic cell is already in a critical state. The alumina concentration is the critical alumina concentration under the process conditions.

[0032] When the electrolytic cell is in the state of critical alumina concentration, the corresponding alumina ...

Embodiment 2

[0036] Collect gas from openings in different areas of a single aluminum electrolytic cell, such as fire holes in different areas. The gas enters the gas analyzer through filtration and drying, and the gas analyzer conducts online continuous analysis of the gas composition, and obtains the CF in the flue gas in real time. 4 concentration, and communicate the analysis results to the aluminum electrolytic cell control system.

[0037] when a CF 4 When the concentration mutation is not zero, that is, the minimum resolution of the detection equipment, such as: 0.01ppm, at this time it can be judged that there has been an electrolytic side reaction near this position, and the local alumina concentration of the electrolytic cell is already in a critical state. , the control system can carry out local effect suppression processing on this area. Add alumina feed to the feeder corresponding to this area. If CF 4 The increase time of each minimum resolution of the gas concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com