Aluminum alloy fin material for heat exchanger and method ofproduction of same and method of production of heat exchanger by brazing fin material

A technology of heat exchangers and aluminum alloys, applied in heat exchange equipment, manufacturing tools, welding/cutting media/materials, etc., can solve the problems of no electrical conductivity and achieve high electrical conductivity, excellent heat transfer characteristics, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

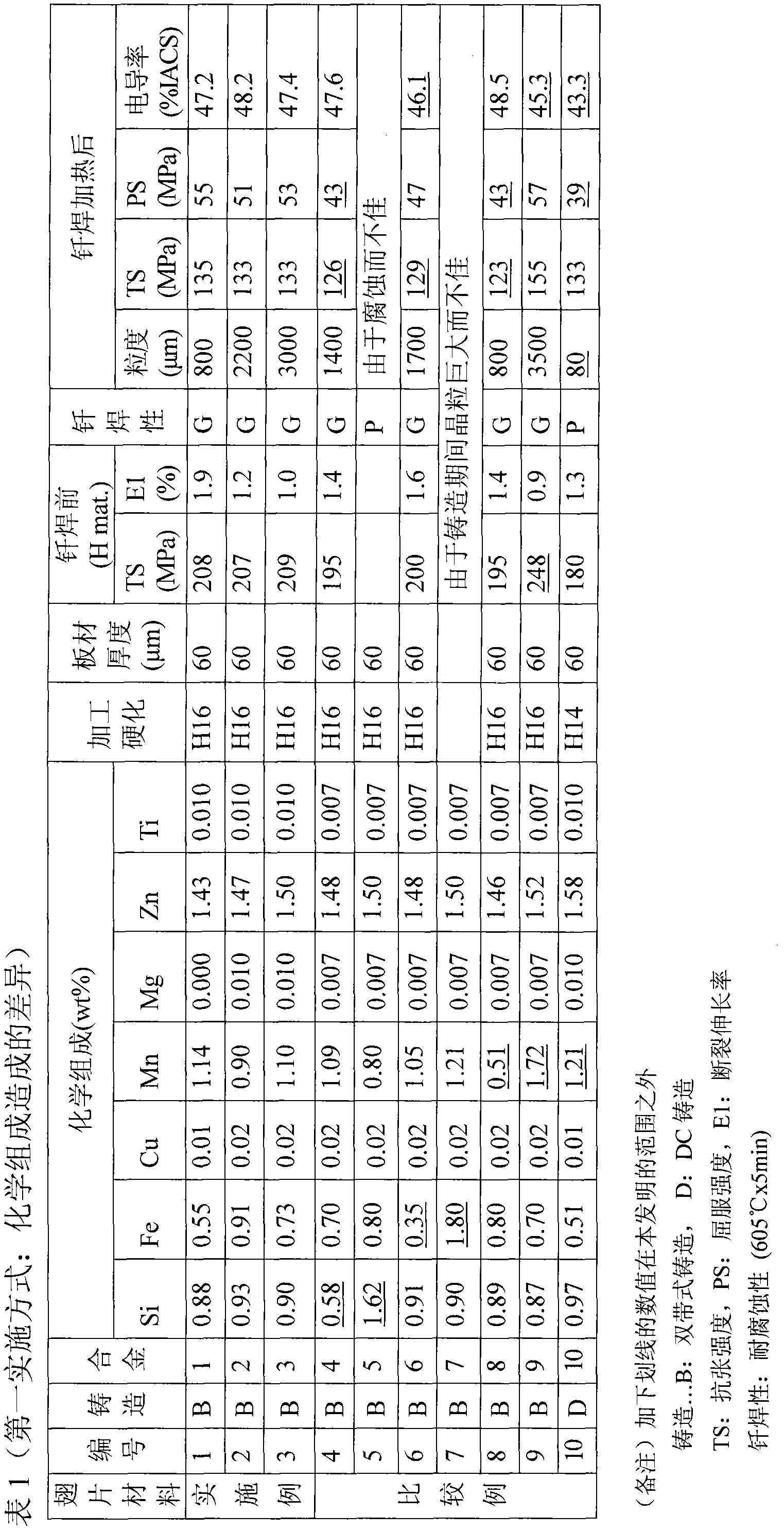

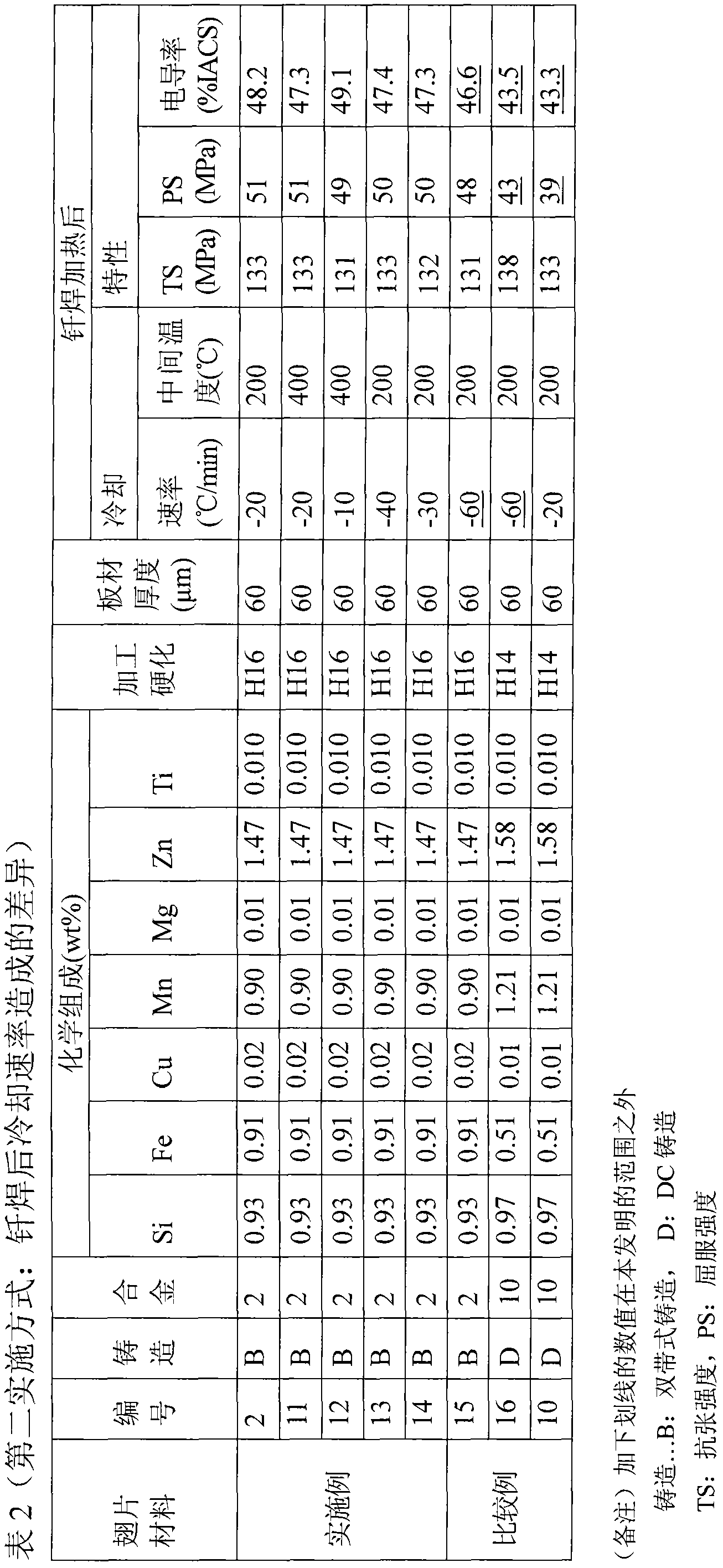

[0066] Hereinafter, examples of the present invention will be explained in comparison with comparative examples.

no. 1 approach

[0068] As an inventive example and a comparative example, alloy melts having the composition of alloy Nos. 1 to 9 shown in Table 1 were produced, passed through a ceramic filter, and poured into a twin-belt casting machine to pass through a casting of 8 m / min. Speed to obtain a slab with a thickness of 7 mm. The cooling rate during solidification of the melt at 1 / 4 of the thickness of the slab was 50°C / sec. The thin slab was cold rolled to 4mm, heated at a heating rate of 50°C / hr, kept at 400°C for 2 hours, and then cooled to 100°C at a cooling rate of 50°C / hr for primary intermediate annealing. Next, the sheet was cold-rolled to 120 μm, heated at a heating rate of 50 °C / hr, held at 400 °C for 2 hours, and then cooled to 100 °C at a cooling rate of 50 °C / hr for secondary intermediate annealing. Next, the plate material was cold-rolled to obtain a fin material having a thickness of 60 μm.

[0069]

[0070]As a comparative example, an alloy melt having the composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com