Metal substrate corrosion prevention coating and preparation method and anticorrosion member

A metal substrate and coating technology, applied in the direction of metal material coating process, coating, mechanical equipment, etc., can solve the problems of brittleness, time lag, difficult to make wire, etc., to improve corrosion resistance, coating Layer stability and strong protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

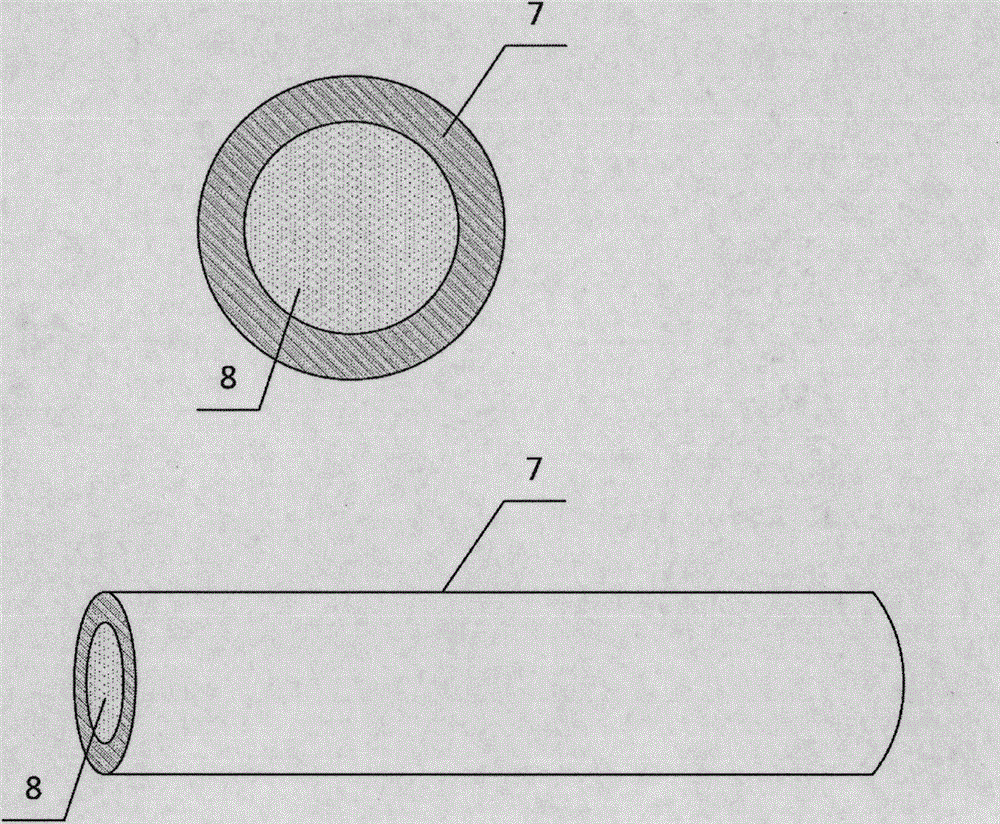

[0103] The preparation method of above-mentioned powder core wire material

[0104] The preparation method of the powder core wire material will be described below:

[0105] The first step is to prepare the outer skin of the alloy belt. Specifically: (1) According to the design composition and proportion of the skin, the pure metal used for the batching can be powder, wire or ingot, especially the impurity content in the raw material used for the batching should meet the requirements of Fe≤0.035 %, Cu≤0.025%, C≤0.02%; (2) At the melting temperature of 750-900°C, melt the pure metal prepared into a molten state in the melting furnace; (3) pour the molten alloy into in the crystallizer, and pull out the solidified alloy casting from the other end of the crystallizer; (4) utilize a rolling mill to hot-roll the alloy casting into an alloy strip; (5) after the hot-rolled alloy strip is cooled, the The alloy strip is surface treated to remove the scale on the surface; (6) the al...

specific Embodiment 1

[0109] Application Environment

[0110]In this embodiment, the coating of the present invention is applied to three in-service light hydrocarbon fuel spherical tanks, the volume of which is 1000 cubic meters, and the inner surface area of each spherical tank is about 484 square meters. These spherical tanks have been in service for more than 10 years, and the average concentration of hydrogen sulfide in the tanks exceeds 3900ppm. This situation has a very negative impact on the safe operation of the spherical tanks. During the annual tank opening inspection, a large number of microcracks with a length of 20mm-50mm can be found on the inner wall of the spherical tank. In order to eliminate hidden dangers of accidents, reduce hazards, and ensure safe and stable long-term operation of hydrocarbon spherical tanks, countermeasures must be taken to avoid equipment accidents. In addition, the installation of these spherical tanks is to weld the bottom plate, wall plate and roof ...

specific Embodiment 2

[0121] Application Environment

[0122] In this embodiment, the coating of the present invention is applied to 6 in-service LNG spherical tanks of a city gas company. The volume of the spherical tanks is 5000 cubic meters, and the inner surface area of each spherical tank is about 1414 square meters. These spherical tanks have been in service for more than 8 years. The average concentration of hydrogen sulfide in the tank exceeds 1500ppm, and the water content in the tank is not less than 300ppm. This situation has a very negative impact on the safe operation of the spherical tank. During the annual tank opening inspection, a large number of microcracks with a length of 10mm-22mm can be found on the inner wall of the spherical tank. Like Example 1, there is also a weld on the base of the spherical tank in this embodiment, and the inner wall of the spherical tank is divided into a weld zone (within 15 cm on both sides of the weld) and a non-weld zone. In addition, there is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com