Detecting device for end-reaching of built-in piston of crust breaking cylinder of electrolytic cell

The technology of a shelling cylinder and a detection device is applied in the field of detection devices for whether the shelling cylinder of a pre-baked electrolytic cell is in the end. , reduce the number of occurrences, and relieve the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

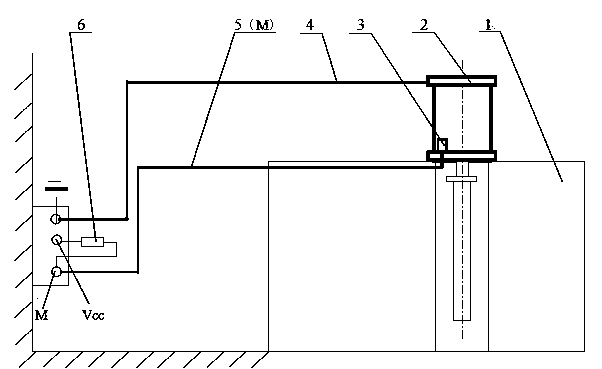

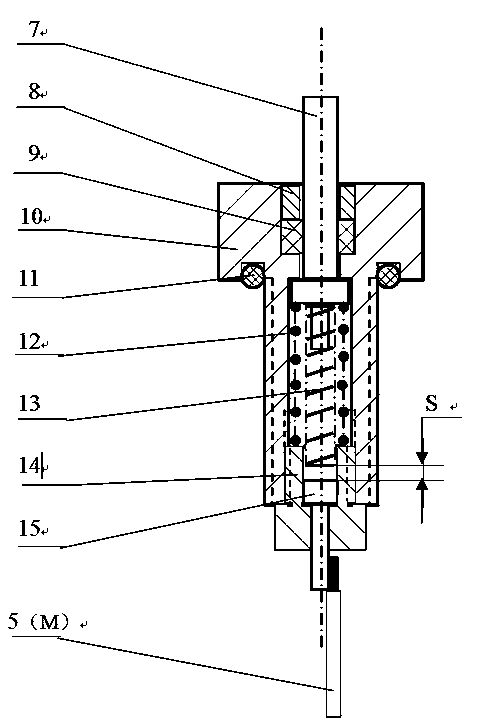

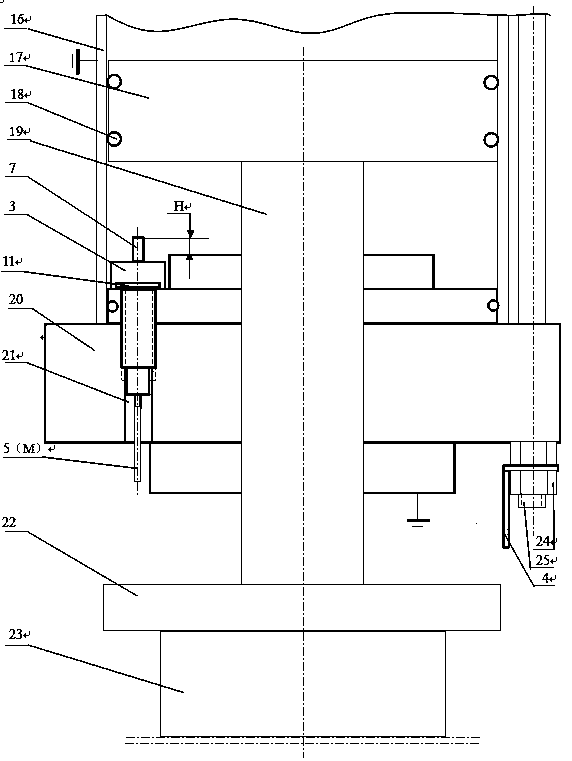

[0017] Such as figure 1 Shown: a detection device with a built-in piston in the shelling cylinder of an electrolytic cell, including a shelling cylinder 2 and an electrolytic cell 1, and the electrolytic cell 1 includes a DC power supply Vcc; the detection device also includes a built-in detection sensor 3 and a pull-up resistor 6; see image 3 , the steel flange 20 at the bottom of the shelling cylinder 2 is provided with a threaded mounting hole 21, the built-in detection sensor 3 is installed in the threaded mounting hole 21, the lower end of the built-in detection sensor 3 is connected with a high temperature resistant pulse wire 5, and the other end of the high temperature resistant pulse wire 5 Lead out from the shelling cylinder 2 to the Vcc DC power supply box below the electrolytic tank 1, and connect with the pull-up resistor 6, the other end of the pull-up resistor 6 is connected with the DC power supply Vcc, and connected to the Vcc DC power supply, so that the bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com