Gasoline engine oil composition and preparation method thereof

A technology for gasoline engine oil and composition, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve problems such as strong steric hindrance effect, and achieve the effects of simple and easy preparation method, excellent anti-oxidation performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

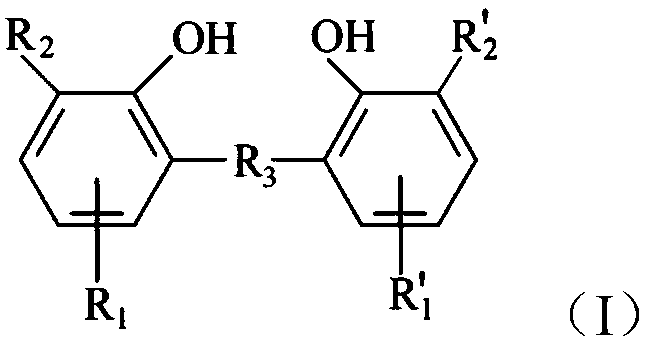

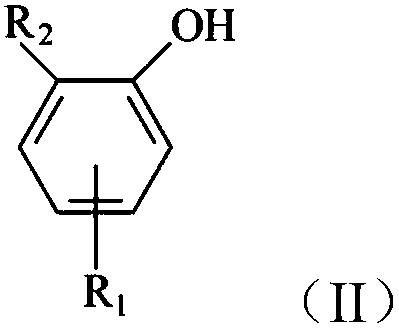

Method used

Image

Examples

Embodiment 1

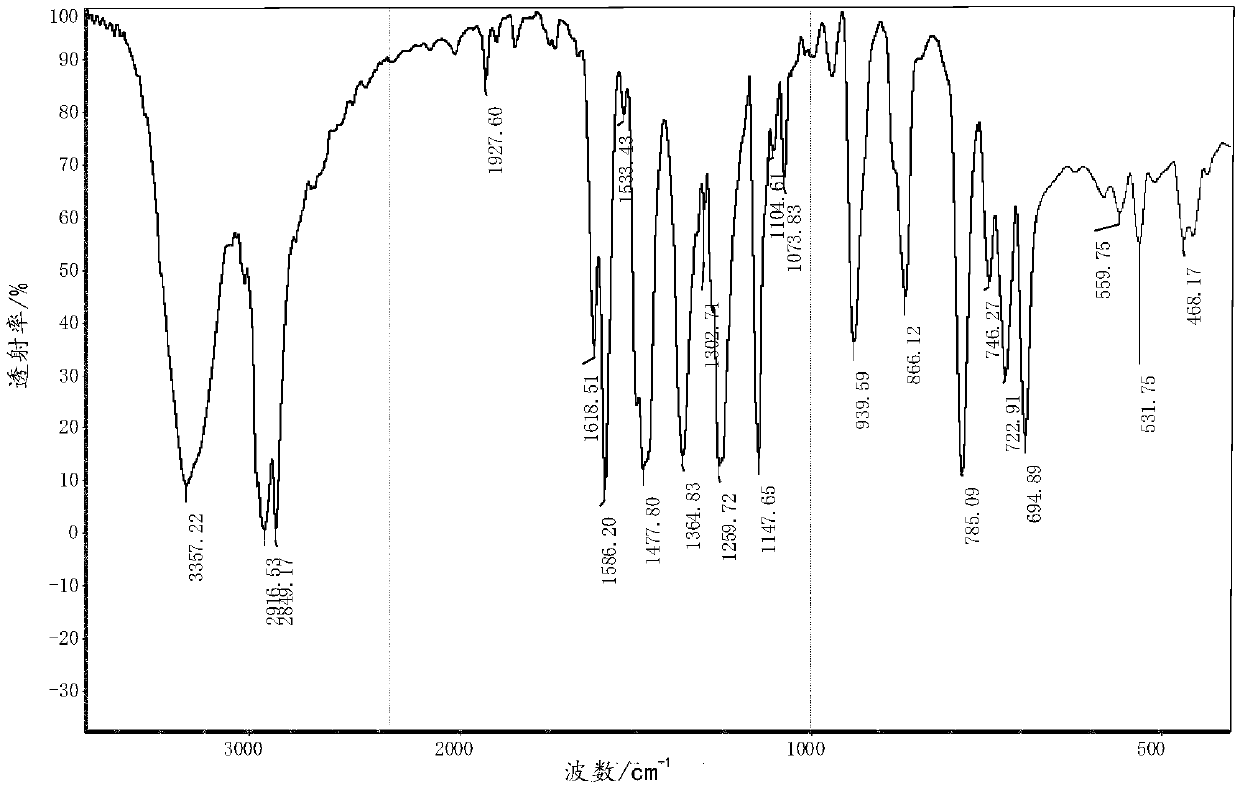

[0069] The preparation of embodiment 1 pentadecylphenol

[0070] Put 100g of cardanol and 1.5g of palladium-carbon catalyst into a 200ml autoclave, seal the autoclave, feed hydrogen to 3.5MPa, start stirring, heating, and react at 200°C for 4.5 hours. After the reaction was completed, the temperature was lowered to 60°C, and the viscous reaction mixture was taken out, and distilled under reduced pressure at 100 Pa and 160°C for 1 h, and a milky white solid was obtained after cooling. Dissolve it with petroleum ether, and then crystallize and purify to obtain m-pentadecylphenol with a purity greater than 98%, and the reaction conversion rate is 83.6%.

Embodiment 2

[0071] The preparation of embodiment 2 6-tert-butyl cardanol

[0072] Dissolve 30g of cardanol into 100ml of acetone, put it into a 250ml three-necked flask, add 0.9g of zinc chloride catalyst, start stirring and heating. Maintaining the reaction temperature at 60°C, 9.5 g of tert-butyl chloride was slowly added dropwise into the reaction flask, and the reaction was continued for 3 hours after the dropwise addition was completed. After the reaction, the temperature was lowered to obtain a brown-red transparent liquid. After filtering the reaction product, wash it with 5% KOH solution, then wash it with distilled water to neutrality, distill under reduced pressure at 1000Pa and 120°C for 1h, remove the solvent, water and unreacted raw materials, and obtain a brown-red transparent viscous The thick liquid is 6-tert-butylcardanol, and the conversion rate of the product is 85.1%.

Embodiment 3

[0073] Example 3 Preparation of 3-pentadecyl-6-tert-butylphenol

[0074] Dissolve 30g of m-pentadecylphenol into 100ml of acetone, put it into a 250ml three-necked flask, add 1.5g of zinc chloride catalyst, start stirring and heating. Maintaining the reaction temperature at 50°C, 9.5 g of tert-butyl chloride was slowly added dropwise into the reaction flask, and the reaction was continued for 5 hours after the dropwise addition was completed. After the reaction, the temperature was lowered to obtain a brown-red transparent liquid. After filtering the reaction product, wash it with 5% KOH solution, then wash it with distilled water until it is neutral, distill it under reduced pressure at 1000Pa and 120°C for 1h, remove the solvent, water and unreacted raw materials, and obtain an orange-yellow color after cooling down. The solid is 3-pentadecyl-6-tert-butylphenol, and the conversion rate of the product is 80.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com