Aluminum oxide breaking and unloading integrated device and aluminum oxide breaking and unloading integrated method for aluminum electrolysis cell

An aluminum electrolytic cell and alumina technology, which is applied in the field of aluminum electrolysis, can solve the problems of easy formation of electrolyte nodules and complicated devices by a shell hammer, and achieve the effects of solving the electrolyte nodules, improving the dissolution rate and facilitating maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

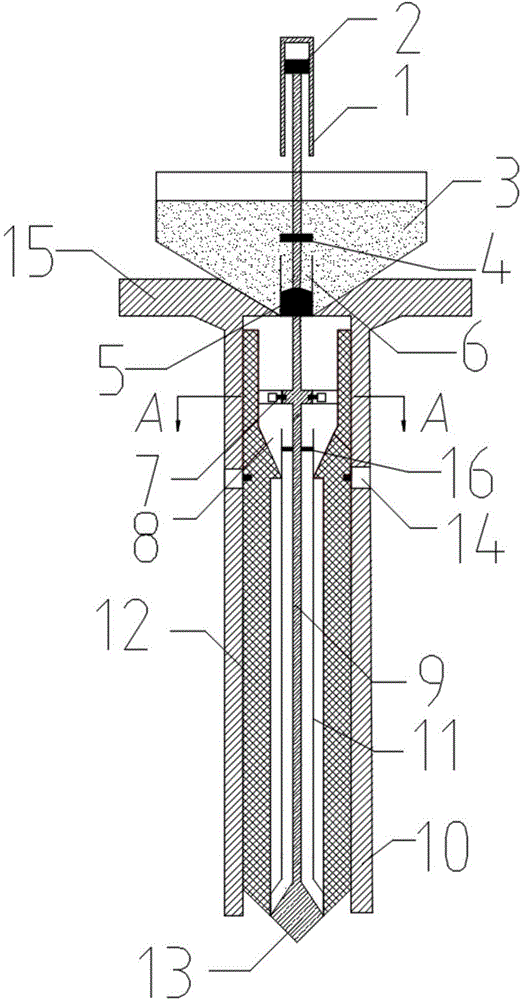

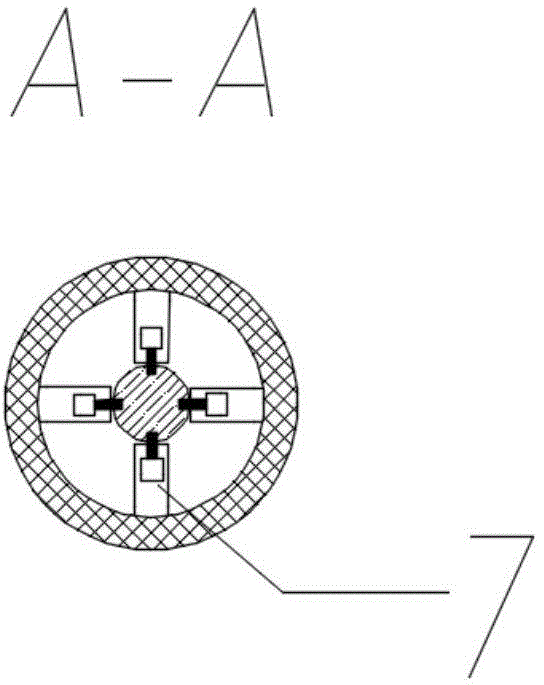

[0027] The structure diagram of this embodiment is as follows figure 1 Shown:

[0028] This embodiment comprises cylinder, material box, constant volume device, hammerhead rod, steel cylinder, steel cylinder hammerhead rod linkage device and steel cylinder fixing device, and cylinder, material box, steel cylinder are arranged in order from top to bottom, and hammerhead rod It is vertically set and passes through the material box and the external steel cylinder, and the top is in the cylinder and is equipped with a driving piston driven by the cylinder. The bottom of the hammer rod is equipped with a hammer for striking the crust on the surface of the electrolytic cell. The constant volume device is set In the material box, the constant volume device includes a feed piston, a discharge piston and a constant volume chamber. The constant volume chamber is cylindrical and is set on the opening at the bottom of the feed box. Both the feed piston and the discharge piston are fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com