Air jet spinning unit having spindle-shaped component

A technology of air-jet spinning and parts, which is applied in the field of mandrel-shaped parts, which can solve the problems of processing costs and other problems, and achieve the effect of simplifying processing and assembly costs and eliminating fiber aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

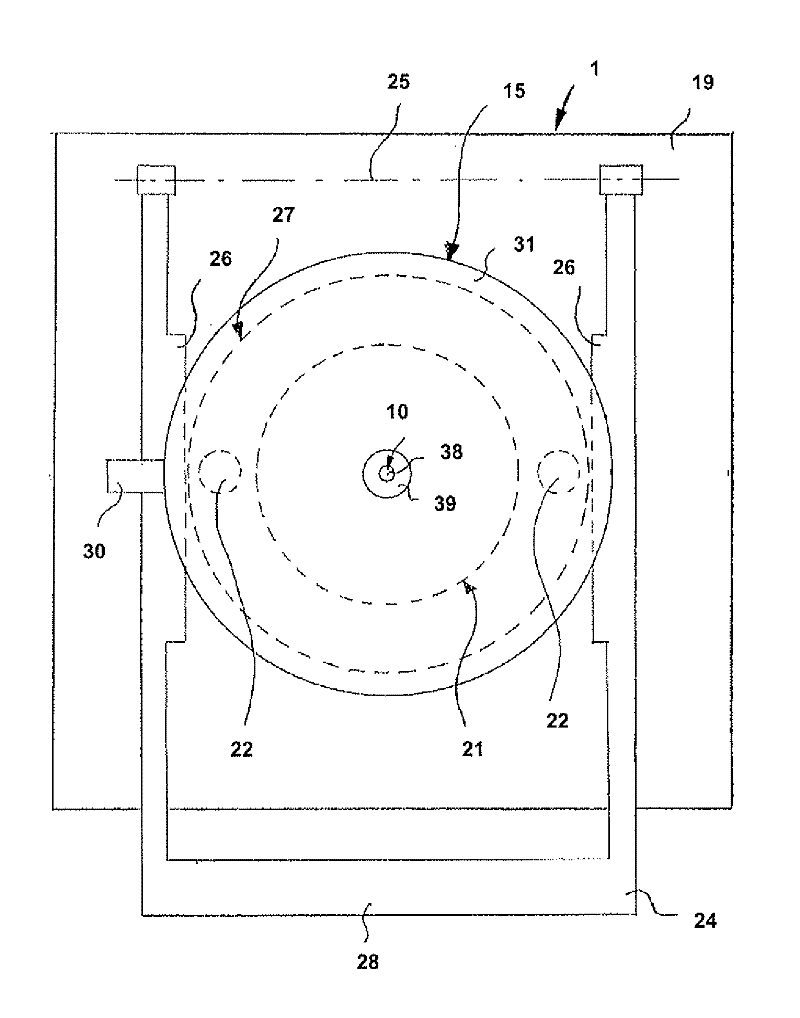

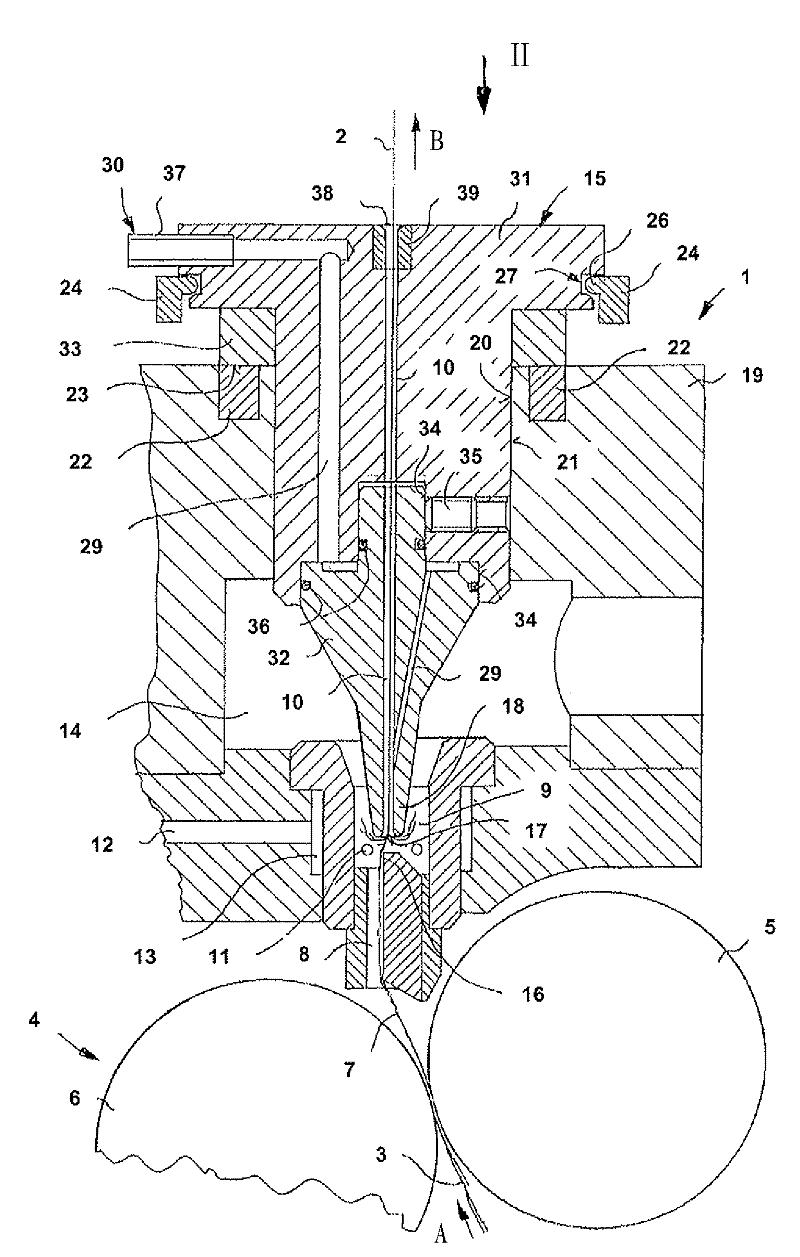

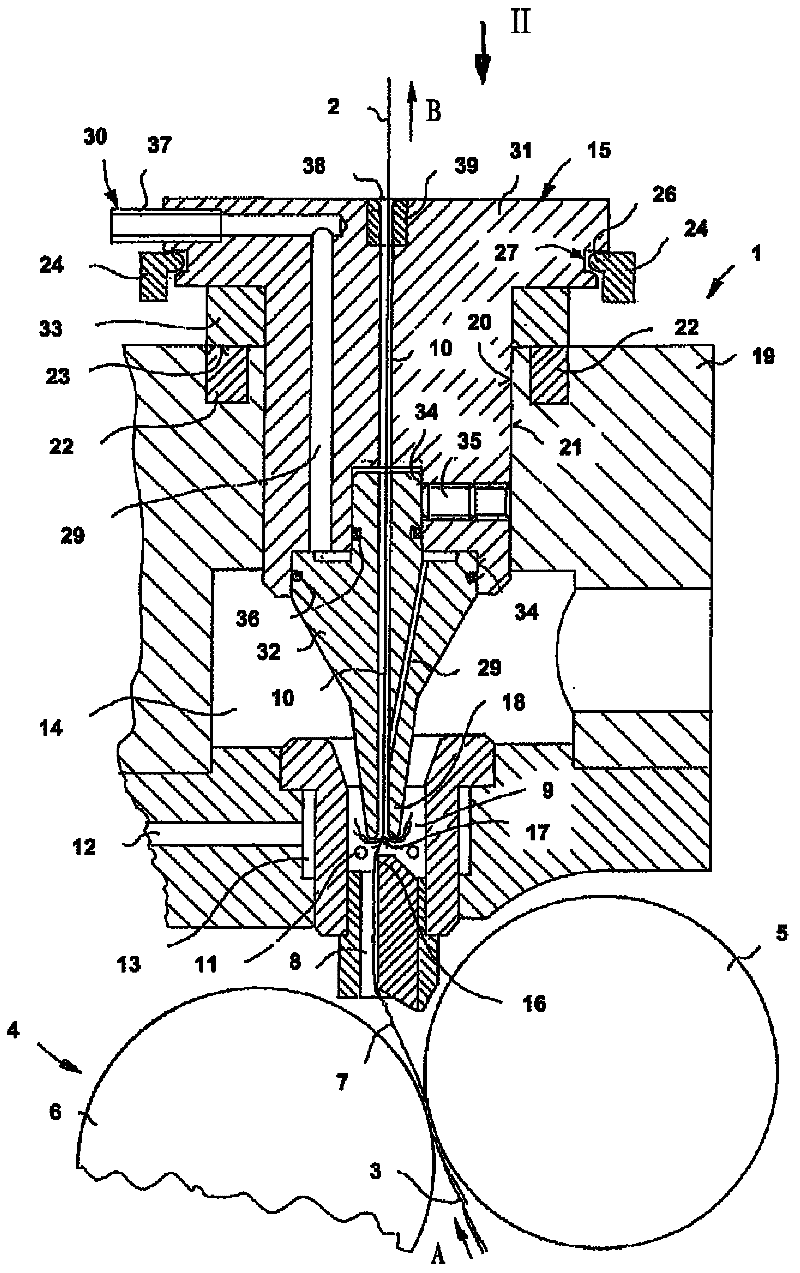

[0020] exist figure 1 The air-jet spinning device shown in is used for processing a spun yarn 2 from a staple fiber sliver 3 . The drafting device 4 is placed in front of the air-jet spinning device 1 .

[0021] The staple fiber strand 3 to be spun is transported in the drafting device 4 in the drafting direction A and is discharged as spun yarn 2 in the yarn discharge direction B and is passed on to a winding device (not shown). The drafting device 4 , which is only partially shown, is preferably a three-roller drafting device and therefore contains a total of three roller pairs, which each have a driven bottom roller and an upper roller formed by pressure rollers. Only the feed roller pairs 5 , 6 which limit the drafting range of the drafting device 4 are shown. In this drafting device 4, the staple fiber strand 3 is drafted to the desired fineness in a known manner. Then the thin fibrous strands 7 appear on the clamping line of the feed roller pair 5,6 in the drafting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com