A flow control device in kr desulfurization hot metal tank

A technology of molten iron tanks and stirring devices, which is applied in the direction of manufacturing tools, casting molten material containers, casting equipment, etc., can solve the problems of desulfurization agent accumulation, etc., to improve utilization rate, eliminate desulfurization agent accumulation, and suppress the formation of central eddy current zone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

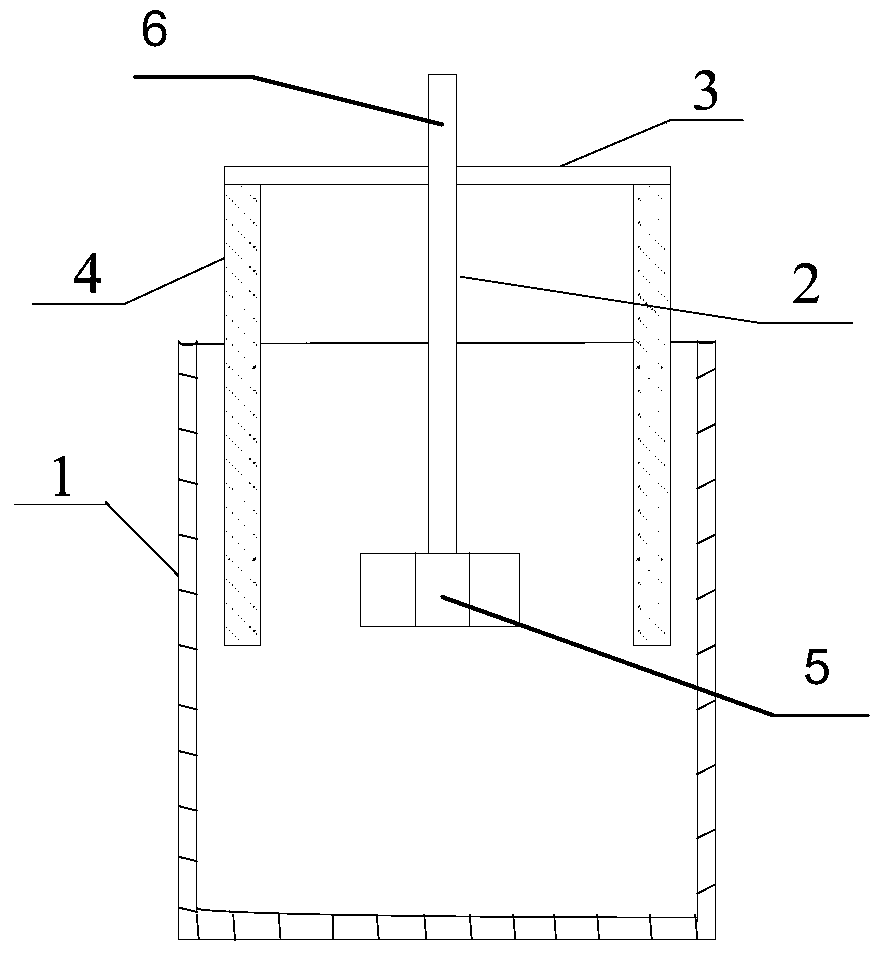

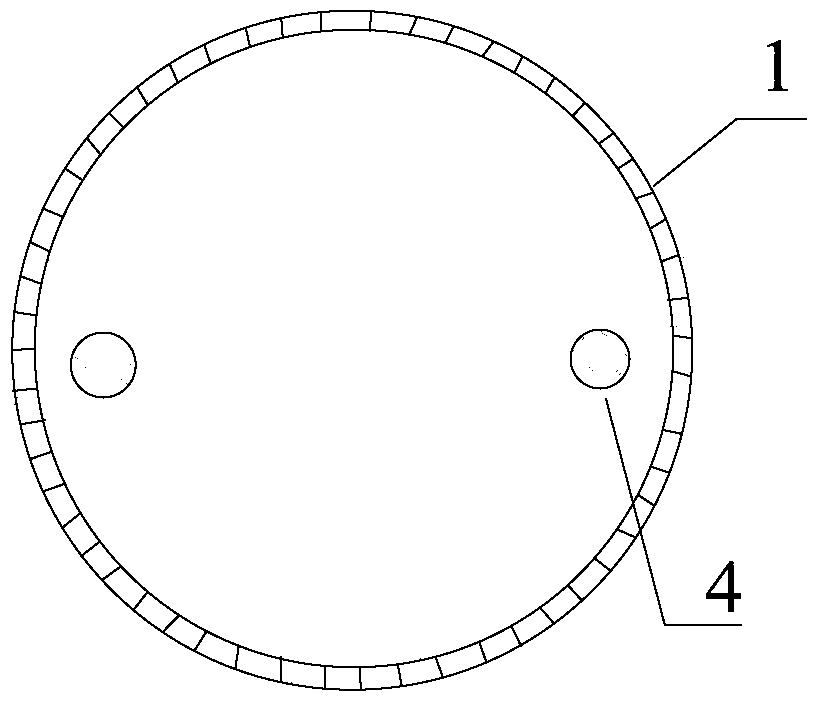

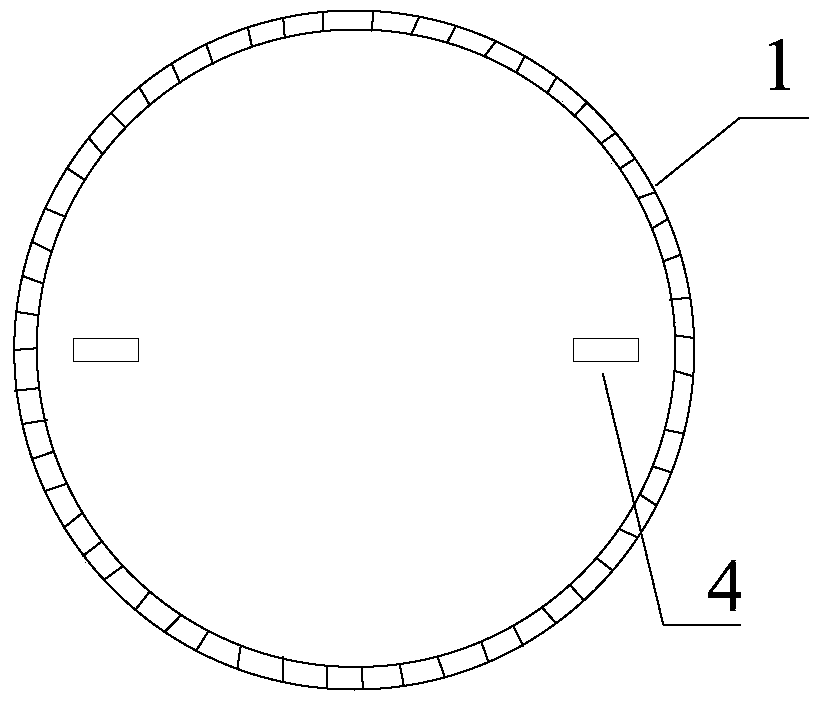

[0025] The flow control device in a KR desulfurization molten iron tank provided by the present invention is as follows: Figure 2-4 As shown, it is the same as the prior art in that it also includes a stirring device 2 inserted into the molten iron tank 1. The stirring device 2 is composed of a stirring head 5 and a stirring rod 6. The difference is that it also includes a bracket 3 and a stop rod 4. The bracket 3 is installed above the molten iron tank 1. The baffle rod 4 has several strips. The upper ends are distributed and fixedly installed on the bracket 3, and the lower ends are respectively inserted into the molten iron tank 1, and are distributed symmetrically with the stirring rod as the axis.

[0026] As an example, the baffle rod 4 can be made of refractory material, and of course, the baffle rod 4 can also be coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com