Purification method of hydrocyanic acid

A purification method and technology of hydrocyanic acid, applied in the direction of cyanic acid/isocyanic acid, sustainable manufacturing/processing, climate sustainability, etc., can solve reboiler and tower body corrosion, high safety risks, and increase investment Cost and operating costs, etc., to ensure reliability, eliminate aggregation, and shorten residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

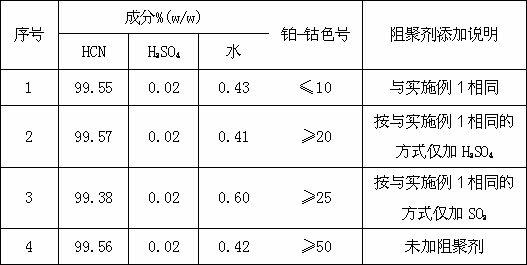

Embodiment 1

[0019] A method for purifying hydrocyanic acid. The purified raw material is prepared by using water as an absorbent to absorb hydrogen cyanide in the hydrogen cyanide synthesis gas produced by the Angle method in an absorption tower. The specific composition is mass percent Content (w / w, the same below) as the following hydrocyanic acid solution: HCN 2.10%, water 97.75%, H 2 SO 4 0.15%; Its rectifying tower adopts the rectifying tower that the diameter is 1200 mm and is filled with acid-resistant ceramic filler, and this rectifying tower has 22 trays altogether, wherein 15 rectifying sections, 7 stripping sections; The purified raw material flows through the feed heater at a flow rate of 12050kg / hour and is heated to 55°C, and then the seventh tray from the bottom enters the rectification column, the temperature at the top of the tower is 19.6°C, and the pressure at the top of the tower is The negative pressure of 80 KPa, the tower still temperature is 94.2 ℃, the tower sti...

Embodiment 2

[0021] A method for purifying hydrocyanic acid, the specific composition of its purified raw materials is as follows: hydrocyanic acid solution: 10.0% HCN, 89.65% water, H 2 SO 4 0.35%; heated to 40°C in the feed heater; the pressure at the top of the tower is a negative pressure of 90 KPa, the temperature of the top of the tower is 25°C, the temperature of the bottom of the tower is 60°C, the pressure of the bottom of the tower is a negative pressure of 95 KPa, reflux The ratio is 15; the purified raw material is added at a flow rate of 12050kg / hour, and the polymerization inhibitor SO is added in an amount of 2.5 liters / hour in the hydrogen cyanide gas steamed from the gas phase outlet pipeline at the top of the tower 2 (gaseous state), add mass concentration in the reflux liquid by the amount of 1.1kg / hour and be that the phosphoric acid aqueous solution of 80% is made polymerization inhibitor, other equipment requirements, operating requirements etc. are the same as embo...

Embodiment 3

[0023] A method for purifying hydrocyanic acid, the specific composition of its purified raw materials is as follows: hydrocyanic acid solution: 8.50% HCN, 91.15% water, H 2 SO 4 0.35%; heated to 50°C in the feed heater; the pressure at the top of the tower is 10 KPa negative pressure, the temperature at the top of the tower is 23.5°C, the temperature of the tower bottom is 90°C, the pressure of the bottom bottom is 90 KPa negative pressure, reflux The ratio is 3; the purified raw material is added at a flow rate of 12050kg / hour, and the polymerization inhibitor SO is added in the amount of 2.5 liters / hour in the hydrogen cyanide gas steamed from the gas phase outlet pipeline at the top of the tower 2 (gaseous state), add mass concentration in the reflux liquid by the amount of 1.0kg / hour and be that 85% formic acid aqueous solution is made polymerization inhibitor; Other equipment requirements, operating requirements etc. are the same as embodiment 1, finally obtain the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com