Device and method for feeding steel scraps into blast furnace for iron making

A technology for blast furnace ironmaking and steel shavings, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of reduced iron yield of Fe element, high energy consumption of electric arc furnaces, and large pollution, etc. High recovery rate, smooth conveying, uniform mixing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

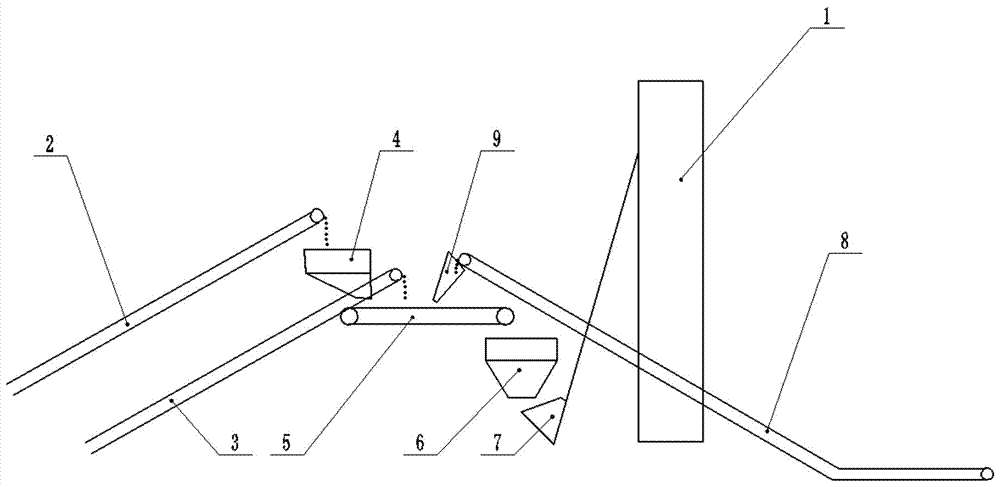

Embodiment 1

[0030] Such as figure 1 As shown, a device for scrap steel shavings into a blast furnace for ironmaking includes an ironmaking blast furnace 1 and a feeding conveyor chain arranged on one side of the ironmaking blast furnace 1. The feeding conveyor chain is composed of three stages, including a primary conveyor chain, The secondary conveyor chain and the tertiary conveyor chain, the primary conveyor chain includes the primary iron ore belt conveyor 2 and the primary coke belt conveyor 3 and the iron ore below the tail end of the primary iron ore belt conveyor 2 Vibrating screen 4, the iron ore it belongs to is sintered iron ore, and the secondary conveying chain is the secondary conveying belt 5 located below the iron ore vibrating screen 4 and the primary coke belt conveyor 3, and the tertiary conveying chain is located at the The tertiary hopper 6 at the tail end of the secondary conveyor belt 5 and the tertiary bucket elevator 7 located below the tertiary hopper 6 are compo...

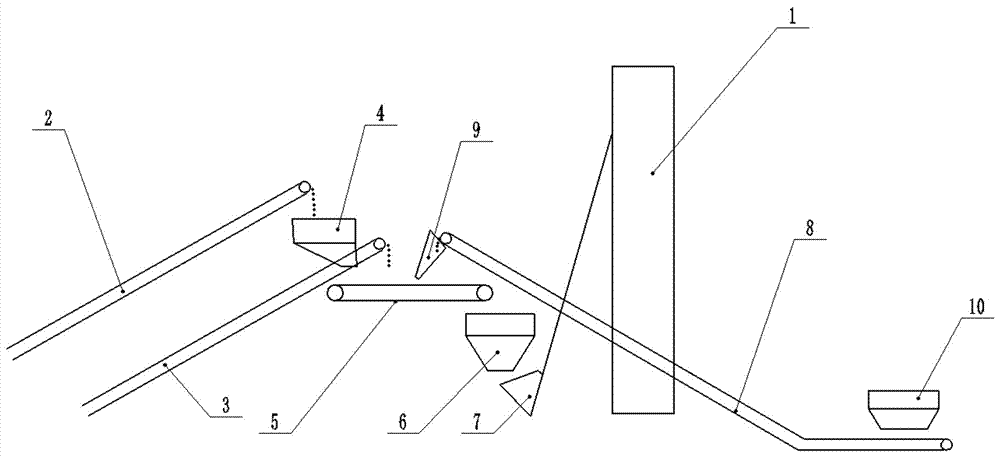

Embodiment 2

[0037] Such as figure 2As shown, a device for scrap steel shavings into a blast furnace for ironmaking includes an ironmaking blast furnace 1 and a feeding conveyor chain arranged on one side of the ironmaking blast furnace 1. The feeding conveyor chain is composed of three stages, including a primary conveyor chain, The secondary conveyor chain and the tertiary conveyor chain, the primary conveyor chain includes the primary iron ore belt conveyor 2 and the primary coke belt conveyor 3 and the iron ore below the tail end of the primary iron ore belt conveyor 2 The vibrating screen 4, the iron ore belonging to it is sintered iron ore and lump ore, the secondary conveying chain is the secondary conveying belt 5 located below the iron ore vibrating screen 4 and the primary coke belt conveyor 3, and the tertiary conveying chain It consists of a tertiary hopper 6 located at the tail end of the secondary conveyor belt 5 and a tertiary bucket elevator 7 located below the tertiary ho...

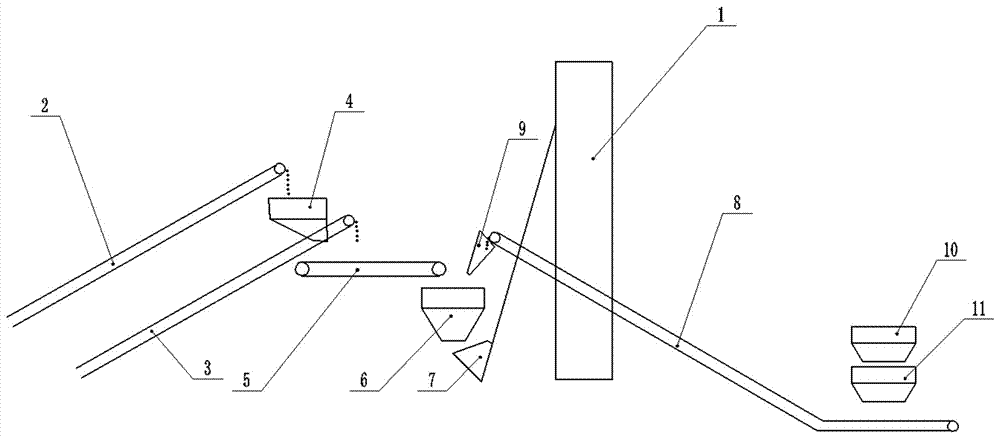

Embodiment 3

[0043] Such as image 3 As shown, a device for scrap steel shavings into a blast furnace for ironmaking includes an ironmaking blast furnace 1 and a feeding conveyor chain arranged on one side of the ironmaking blast furnace 1. The feeding conveyor chain is composed of three stages, including a primary conveyor chain, The secondary conveyor chain and the tertiary conveyor chain, the primary conveyor chain includes the primary iron ore belt conveyor 2 and the primary coke belt conveyor 3 and the iron ore below the tail end of the primary iron ore belt conveyor 2 Vibrating screen 4, the iron ore to which it belongs is sintered iron ore, and the secondary conveying chain is the secondary conveying belt 5 located below the conveying vibrating screen 4 and the primary coke belt conveyor 3, and the tertiary conveying chain is located at the The third-stage hopper 6 at the tail end of the secondary conveyor belt 5 and the third-stage bucket elevator 7 located below the third-stage ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com