Heat dissipation method and device for integrated heat pipe of large-power LED

A high-power, integrated technology, applied in lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of low heat transfer efficiency and large contact thermal resistance of heat pipes, and achieve simple structure and low Thermal stress, effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

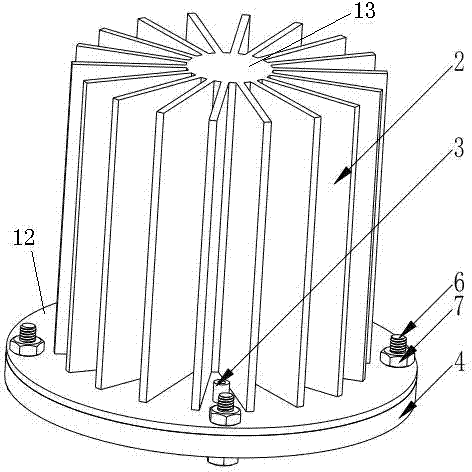

[0041] Such as figure 1 , 5 shown.

[0042] A method for dissipating heat with an integral heat pipe for high-power LEDs, comprising the following steps:

[0043] First, a plurality of cylindrical small-diameter gravity straight heat pipes are installed vertically side by side in the fixed body of the upper shell to form an array of small-diameter gravity heat pipes, and there is no communication between the vertical heat pipes; each heat pipe The wall and the fixed body of the upper casing are preferably in close contact without gaps to achieve better heat conduction. The fixed body 13 of the upper casing 12 is integrally connected with rectangular heat dissipation fins 2, wherein the gravity direct heat pipe 1, the fins 2 are made of aluminum alloy or copper material with good heat dissipation performance;

[0044] Secondly, make the evaporation ends at the lower ends of all the gravity heat pipes 1 communicate with the groove 5 on the lower cover plate 4 to form a common...

Embodiment 2

[0048] Such as Figure 1-4 shown.

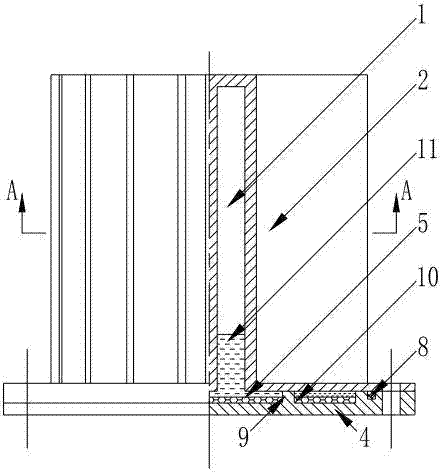

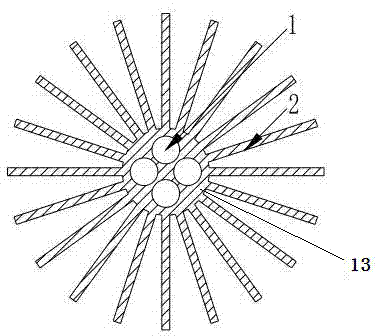

[0049] An integrated heat pipe cooling device for high-power LEDs, which includes an upper case 12 and a lower cover 4 connected to each other, the upper case 12 and the lower cover 4 are connected by bolts 6 and nuts 7, and there is an additional Equipped with rubber gasket 8 for sealing, such as figure 1 , the LED light source is mounted on the bottom surface of the lower cover plate 4, the upper surface of the lower cover plate 4 is provided with a groove 5, and a number of support columns 9 are arranged in the groove 5 ( figure 1 ) to prevent deformation due to pressure changes in the chamber, the groove 5 forms a common evaporation chamber with the lower surface of the upper shell 12 ( figure 2 ); the upper shell 12 is provided with a cylindrical fixed body 13 for fixing the gravity direct heat pipe 1, and the gravity direct heat pipe 1 is arranged around the center of the cylindrical fixed body 13, as image 3 The tube wall of each...

Embodiment 3

[0057] Such as Figure 5 , 6 .

[0058] The difference between this embodiment and embodiment 1 is that the arrangement of the gravity straight heat pipe 1 is different, Figure 5 , 6 The medium-gravity direct heat pipe 1 is fixed in the long waist-shaped fixing body 13 and is arranged in a straight line, which is suitable for narrow and long LED devices, and the rest is exactly the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com