A control method and device for a water washing robot for live equipment

A technology of electrified equipment and control method, applied in the direction of using optical methods for testing, instruments, manipulators, etc., can solve problems such as inability to locate arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

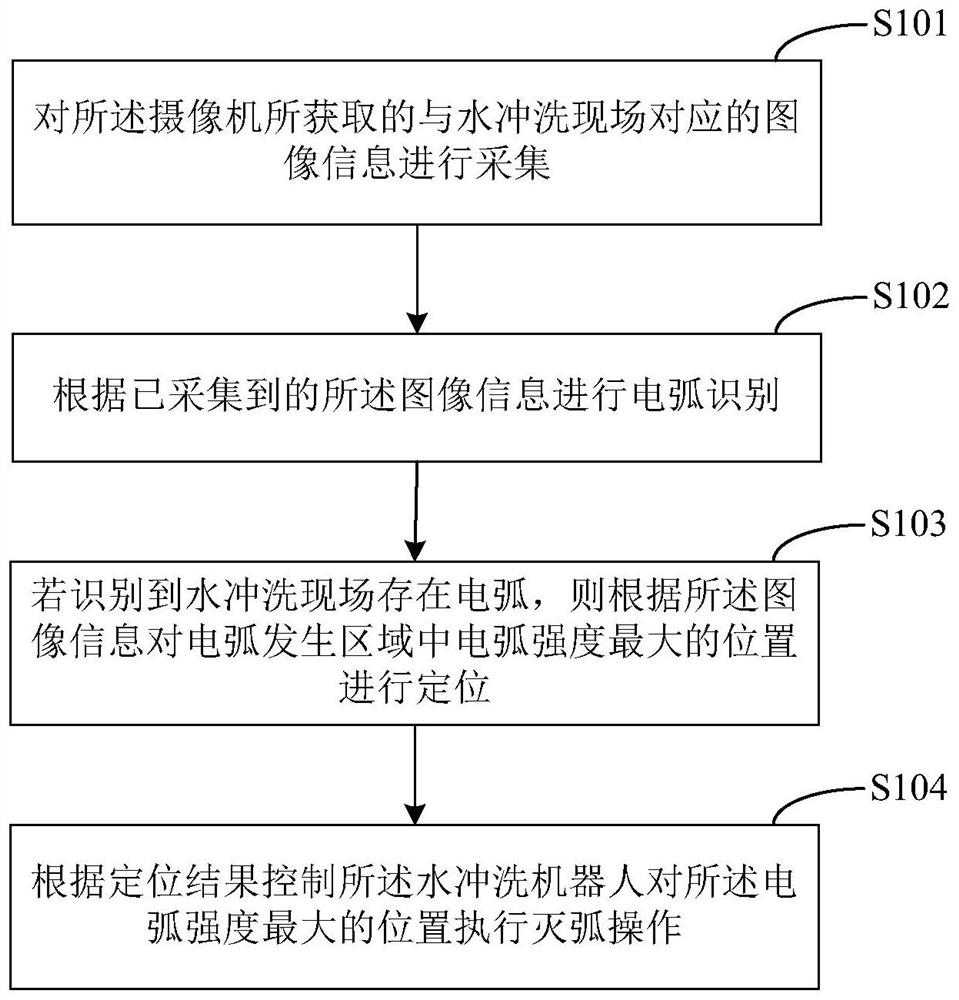

[0025] figure 1 It shows the implementation process of the control method of the charged equipment water washing robot provided by Embodiment 1 of the present invention. For the convenience of description, only the parts related to this embodiment are shown, and the details are as follows:

[0026] In step S101, the image information corresponding to the water flushing scene acquired by the camera is collected.

[0027] In the embodiment of the present invention, the image information corresponding to the water flushing scene acquired by the above-mentioned camera is specifically: within a preset distance, the image obtained by the camera shooting an image of the flushing target in the water flushing scene Therefore, the above step S101 is to collect the image information obtained through the camera shooting after the camera shooting is completed. Wherein, step S101 may specifically be:

[0028] The image information corresponding to the water flushing scene acquired by the ...

Embodiment 2

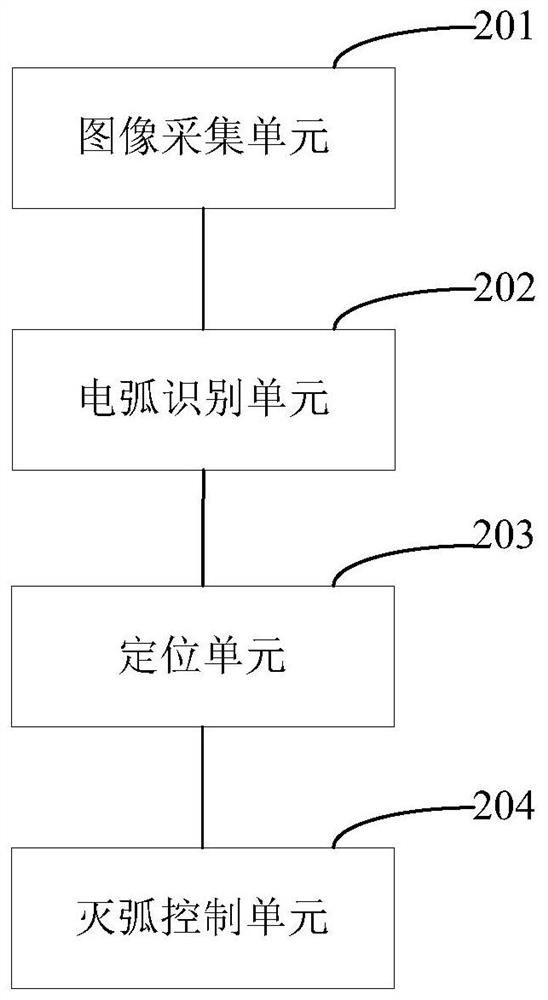

[0052] Embodiment 2 of the present invention provides a control device 20 of a water washing robot for charged equipment, such as figure 2 As shown, the control device 20 of the water washing robot for charged equipment includes an image acquisition unit 201 , an arc identification unit 202 , a positioning unit 203 and an arc extinguishing control unit 204 .

[0053] The image acquisition unit 201 is configured to acquire the image information corresponding to the water flushing scene acquired by the camera.

[0054] The arc identification unit 202 is configured to perform arc identification according to the collected image information.

[0055] The positioning unit 203 is used for locating the position with the highest arc intensity in the arc occurrence area according to the image information if the arc identification unit recognizes that there is an arc in the water flushing site.

[0056] The arc extinguishing control unit 204 is used to control the water washing robot t...

Embodiment 3

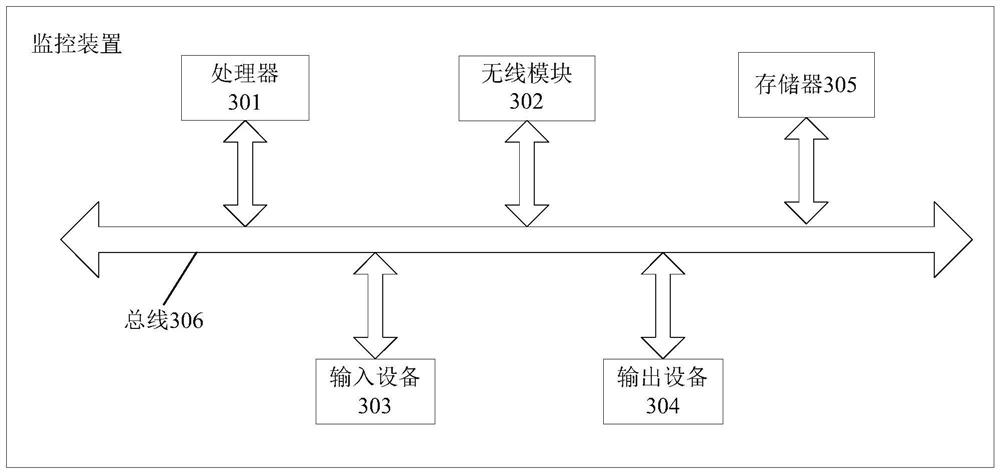

[0081] Embodiment 3 of the present invention provides a control device 30 of a water washing robot for charged equipment, such as image 3 As shown, the control device 30 of the charged equipment water washing robot includes one or more processors 301 (only one is shown in the figure); one or more wireless modules 302 (only one is shown in the figure); one or more input device 303 (only one shown in the figure), one or more output devices 304 (only one shown in the figure) and memory 305 . The aforementioned processor 301 , wireless module 302 , input device 303 , output device 304 and memory 305 are connected through a bus 306 . Among them: the processor 301 is used to collect the image information corresponding to the water flushing scene acquired by the camera, and perform arc identification according to the collected image information. Position the position with the highest arc intensity in the occurrence area, and control the water washing robot to perform arc extinguish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com